Amido aniline group zinc compound and preparation method and application thereof

An aminoaniline, zinc compound technology is applied in the field of catalysts for ring-opening polymerization of cyclic lactones, can solve the problems of low catalytic activity, uncontrollable molecular weight, wide molecular weight distribution of polymers, etc., and achieves high catalytic activity and simple preparation method. , the effect of less metal residue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

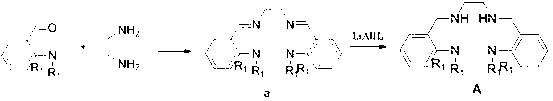

[0045] Take N, N-dimethylaminobenzaldehyde (8.8 g, 59 mmol) and dissolve it in 30 ml of hexane, slowly add ethylenediamine (1.8 g, 29.5 mmol) dropwise, after the dropwise addition, the reaction is heated under reflux and stirred 12 hours. After cooling and crystallization, 7.2 g of yellow powder Schiff's base was obtained by filtration, with a yield of 76%.

Embodiment 2

[0047] in N 2 Under the atmosphere, take the Schiff base (5.0 g, 15.5 mmol) of Example 1 and dissolve it in 30 ml of dry diethyl ether, slowly add lithium aluminum hydride (0.6 g, 15.5 mmol) in small amounts at 0 °C, and add The reaction was then slowly raised to room temperature and stirred for 12 hours. After the reaction, slowly add 1.5 mL of ice water to the reaction system to stop the reaction, then add 1.5 mL of NaOH (3M) aqueous solution, 4.5 mL of water, filter, wash the filter cake with 30 ml of ethyl acetate, collect the filtrate, and remove the solvent in vacuo to obtain light yellow liquid A 5.3 g, 96% yield.

Embodiment 3

[0049] Dissolve N,N-diethylaminobenzaldehyde (7.1 g, 40 mmol) in 40 ml of ethanol, slowly add ethylenediamine (0.8 g, 13.3 mmol) dropwise, and heat the reaction to 50°C after the dropwise addition , stirred for 24 hours. After the reaction, the solution was concentrated, 10 mL of hexane was added to cool and crystallize, and 3.6 g of yellow powder Schiff base was obtained by filtration, with a yield of 71%.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap