Heat-circulation continuous automated coal pyrolysis method

A technology of automatic coal and thermal cycle, applied in the field of coal pyrolysis, to overcome the low production efficiency, reduce the cost of coking, and improve the efficiency of coking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

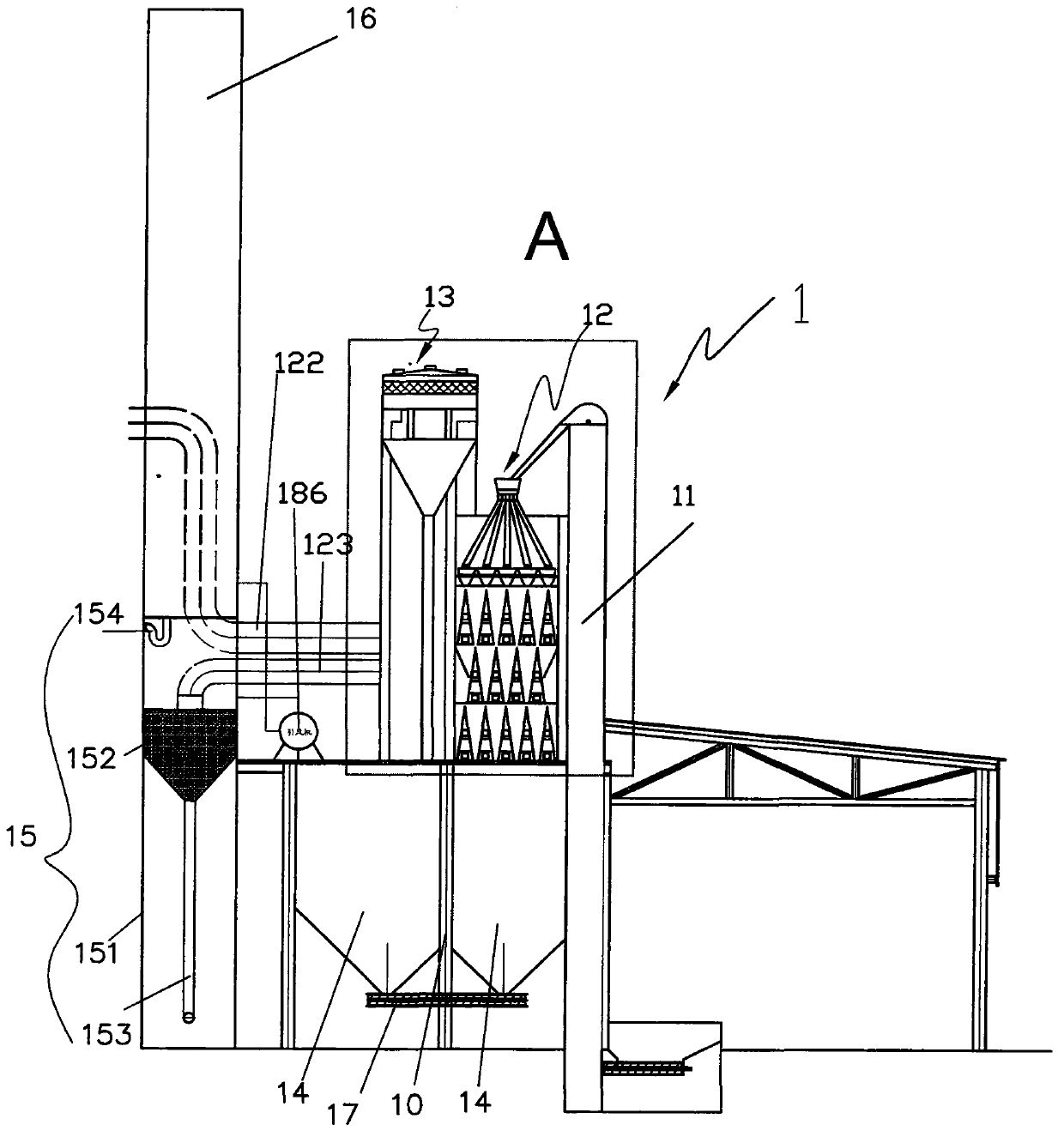

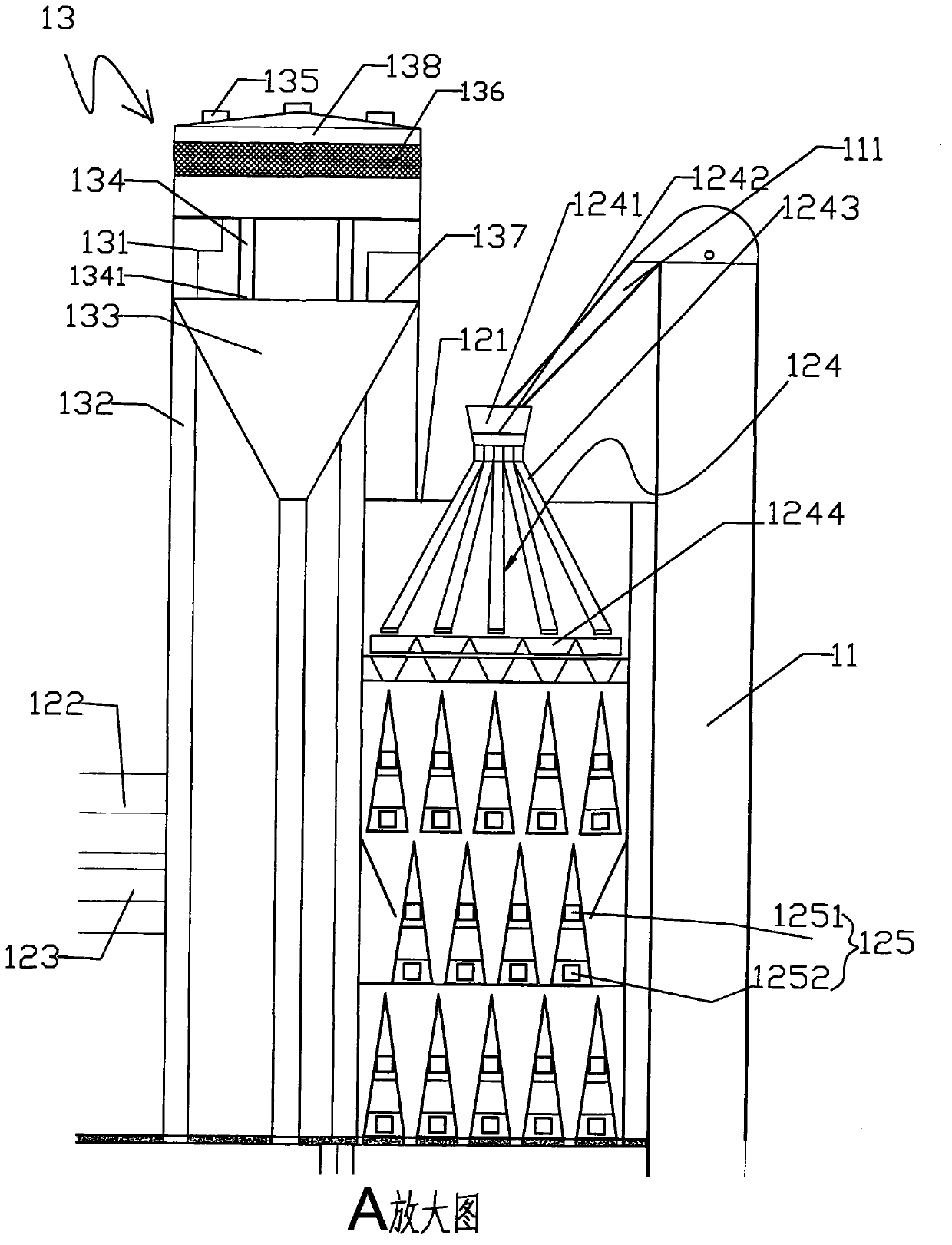

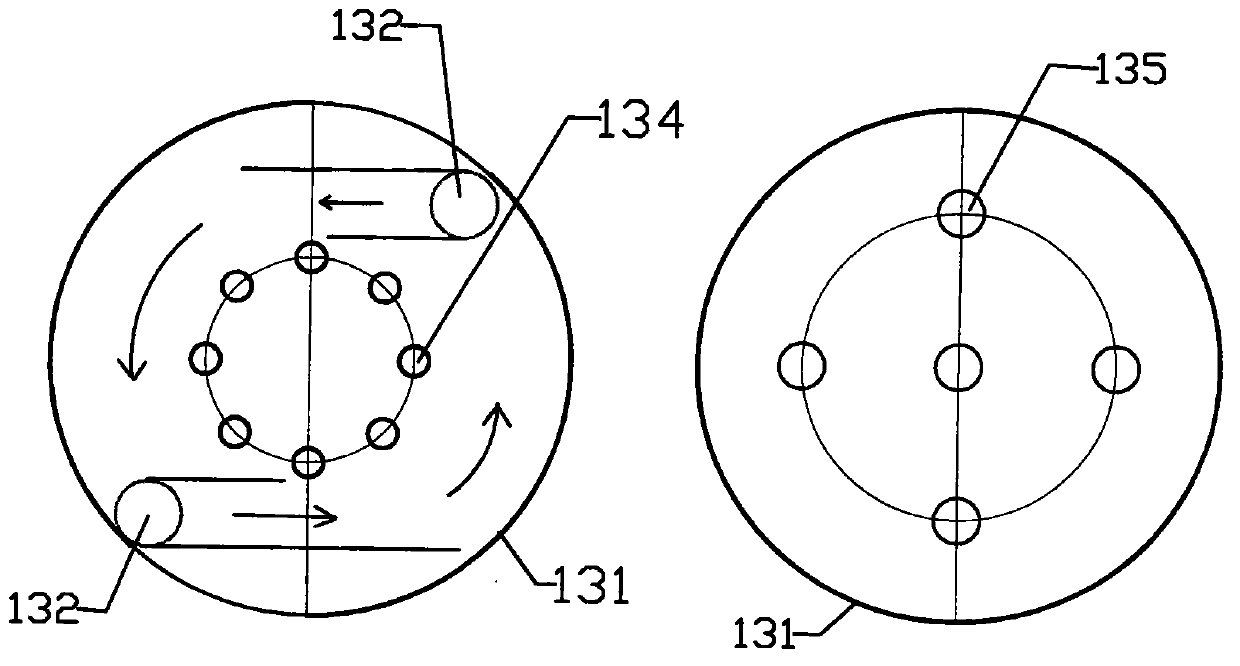

[0062] The specific embodiment of a thermal cycle continuous automatic coal pyrolysis method of the present invention is mainly introduced in detail below.

[0063] Part 1 Furnace Coal Proportion and Preparation

[0064] The coal pyrolysis furnace involved in the present invention can obtain cokes of different grades according to different proportions of coals fed into the furnace.

[0065] The steps are as follows: 1) 5 kinds of different coals are selected, which are respectively gas coal, fat coal, coking coal, one-third coking coal and lean coal. 2) Gas coal 20%~40%; fat coal 10%~20%; coking coal 10%~20%; one-third coking coal 15%~30%; lean coal 10%~15%, first mix and then sieve Broken until the broken particles reach below 5mm to form coal into the furnace. Of course, the coal pyrolysis furnace of the present invention is equally applicable to coal into the furnace with other proportions and particle sizes, and does not constitute a restriction on the required coal powde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com