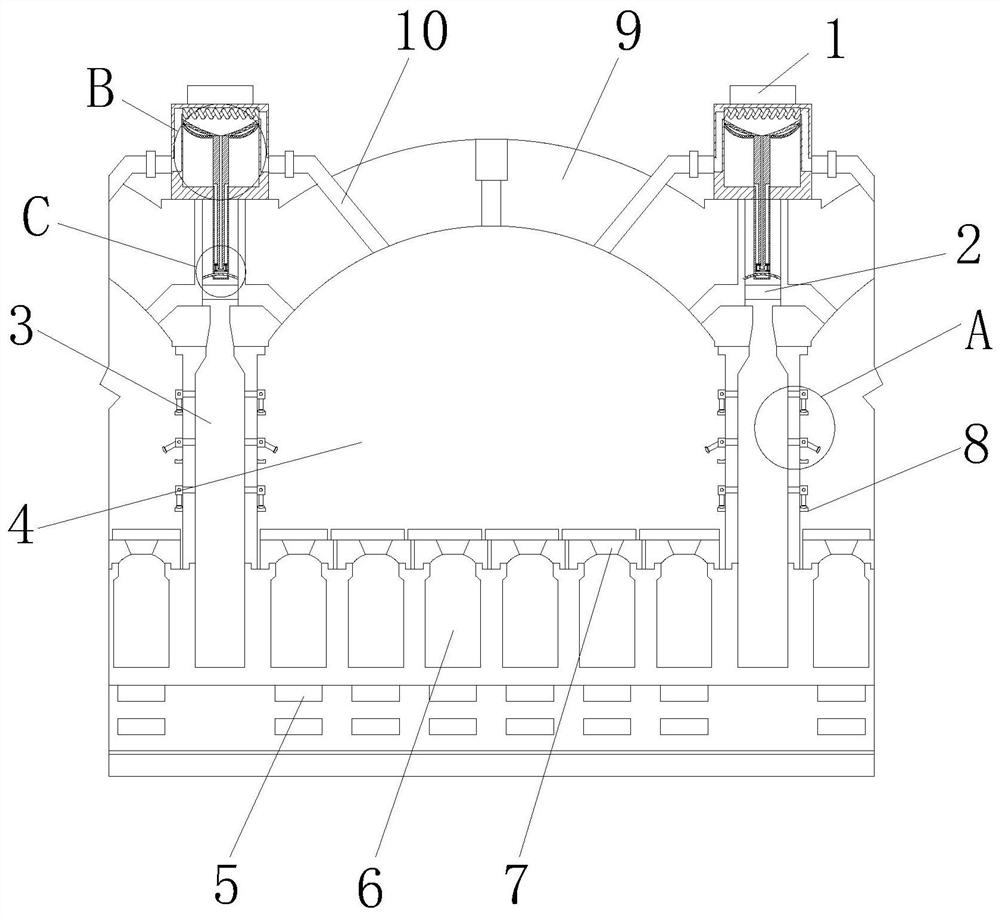

A coke oven for producing molded coke from anthracite

An anthracite and coking oven technology, applied in the field of coking ovens, can solve the problems of inability to preheat coking ovens, reduce coking efficiency, and reduce coking quality, and achieve the effects of enhancing coking effect, facilitating coking, and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

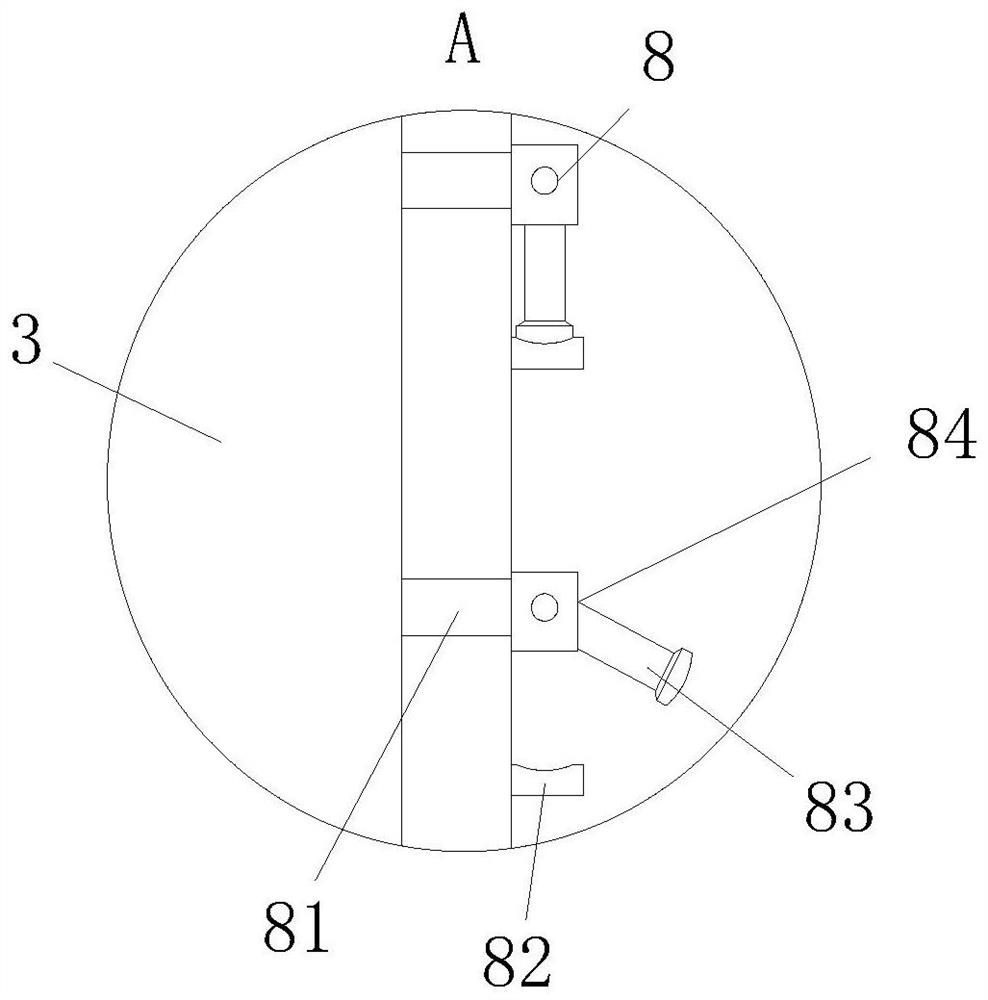

Method used

Image

Examples

Embodiment approach

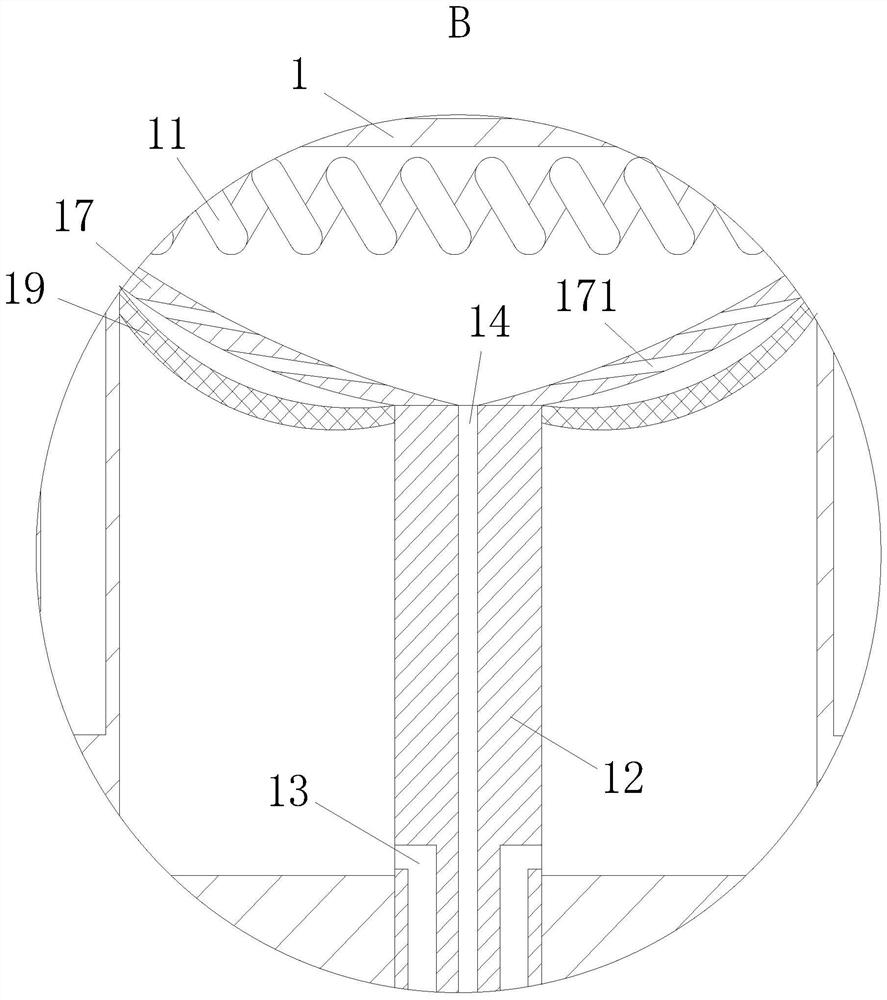

[0026] As an embodiment of the present invention, the lower end of the guide column 12 is fixedly connected with a heat conduction plate 18; the heat conduction plate 18 is inserted into the middle of the U-shaped groove 13 and designed, and the heat conduction plate 18 is made of heat conducting material; A diaphragm 19 is fixedly connected between one end surface in the heat box 1 and the inner wall of the heat collecting box 1; the diaphragm 19 is insulated and made of elastic material, and the diaphragm 19 is designed to be close to the lower surface of the partition plate 17 in the initial state; when working, The contact area between water and heat can be increased through the heat conduction plate 18, thereby increasing the production rate of water vapor and further increasing the preheating rate of the coal to be coked in advance. At the same time, the setting of the diaphragm 19 can ensure the air pressure in the upper and lower heat collecting box 1 of the diaphragm 19...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com