Coal tar modification and coke oven carbonization chamber top coke prevention method and system

A carbonization chamber coal coke and carbonization chamber technology, which is applied in coke ovens, coke oven heating, combustible gas heating coke ovens, etc., can solve the problems of low utilization rate of aromatic ring components, etc. The effect of improving production efficiency and shortening coke cooking time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

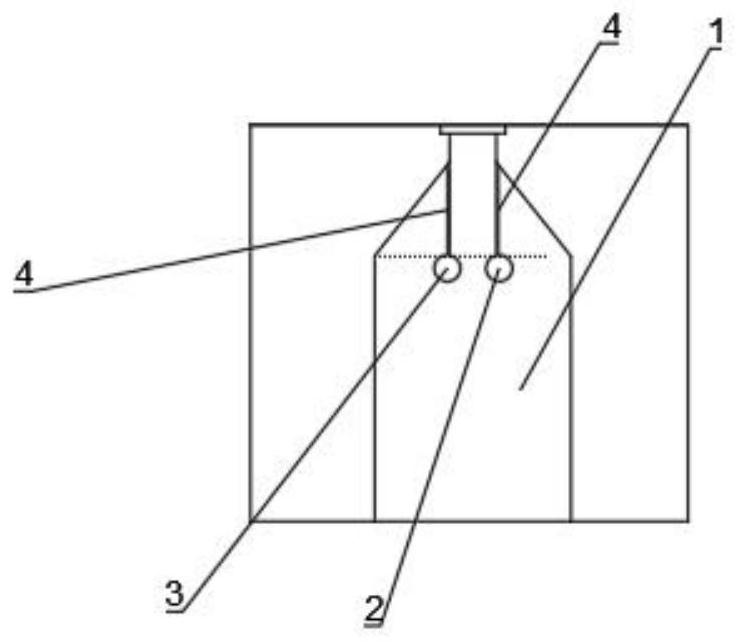

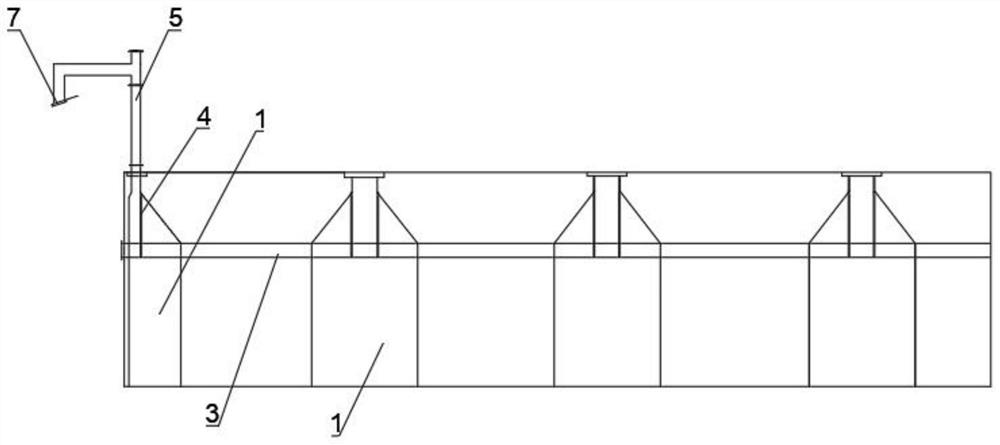

[0037] Such as figure 1 with 2 As shown, this embodiment is used to realize the system of coal tar modification and the coking prevention method at the top of the coke oven carbonization chamber, including the coke oven carbonization chamber 1, the coke oven gas inlet pipe 2 and the water vapor inlet pipe provided on the top of the coke oven carbonization chamber 1 The air pipe 3, the coke oven gas inlet pipe 2 and the water vapor inlet pipe 3 extending into the coke oven carbonization chamber 1 are installed in the coke oven carbonization chamber 1 through the bracket 4, and the inlet pipe 2 and the water vapor inlet pipe extending into the coke oven carbonization chamber 1 A number of air holes are provided on the 3 pipe sections of the water vapor inlet pipe.

[0038] The water vapor introduction method described in the present embodiment:

[0039] Water vapor is fed into the top of the coke oven carbonization chamber 1 through the steam inlet pipe 3 , and coke oven gas i...

Embodiment 2

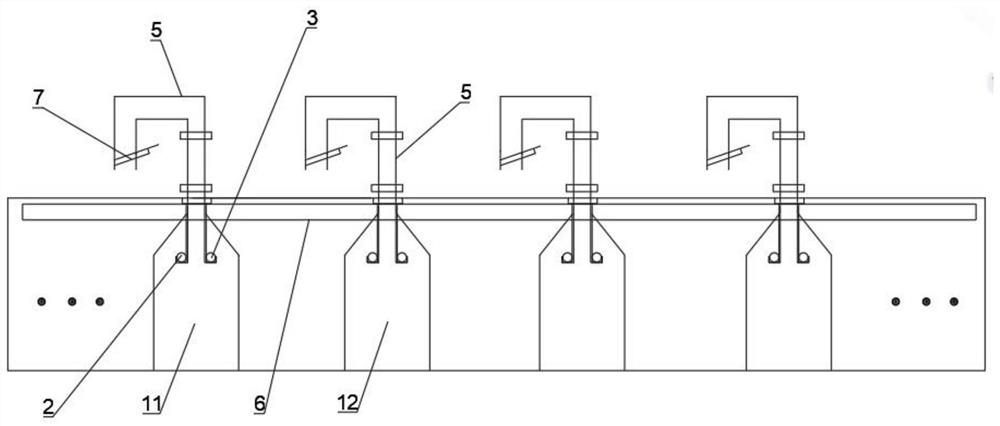

[0042] Such as image 3 As shown, this embodiment is used to realize the system of coal tar modification and the coke prevention method at the top of the coke oven carbonization chamber, including the primary coke oven carbonization chamber 11, the post-generation coke oven carbonization chamber 12, the water vapor inlet pipe 3, the riser pipe 5 and the coke oven carbonization chamber 12. The heat preservation and heat insulation piping system 6; the heat preservation and heat insulation piping system 6 is used to connect the primary coke oven carbonization chamber 11 and the post-generation coke oven carbonization chamber 12; the rising pipe 5 is provided with a flap valve 7; the water vapor inlet pipe 3 It is arranged on the carbonization chamber 11 of the primary coke oven and the top of the carbonization chamber 12 of the post-generation coke oven (such as image 3 shown), or the water vapor inlet pipe 3 is connected with the thermal insulation piping system 6 (such as F...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com