Concentric sliding block simultaneous casing drilling tool, center drilling bit and centralizer

A technology of guiding device and drill bit, applied in drill bit, drilling equipment, earthwork drilling, etc., can solve the problems of easy sticking, large resistance to following the pipe, out-of-round drilling, etc., to reduce the pulling force and slag discharge speed. Faster, less slag fallback effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

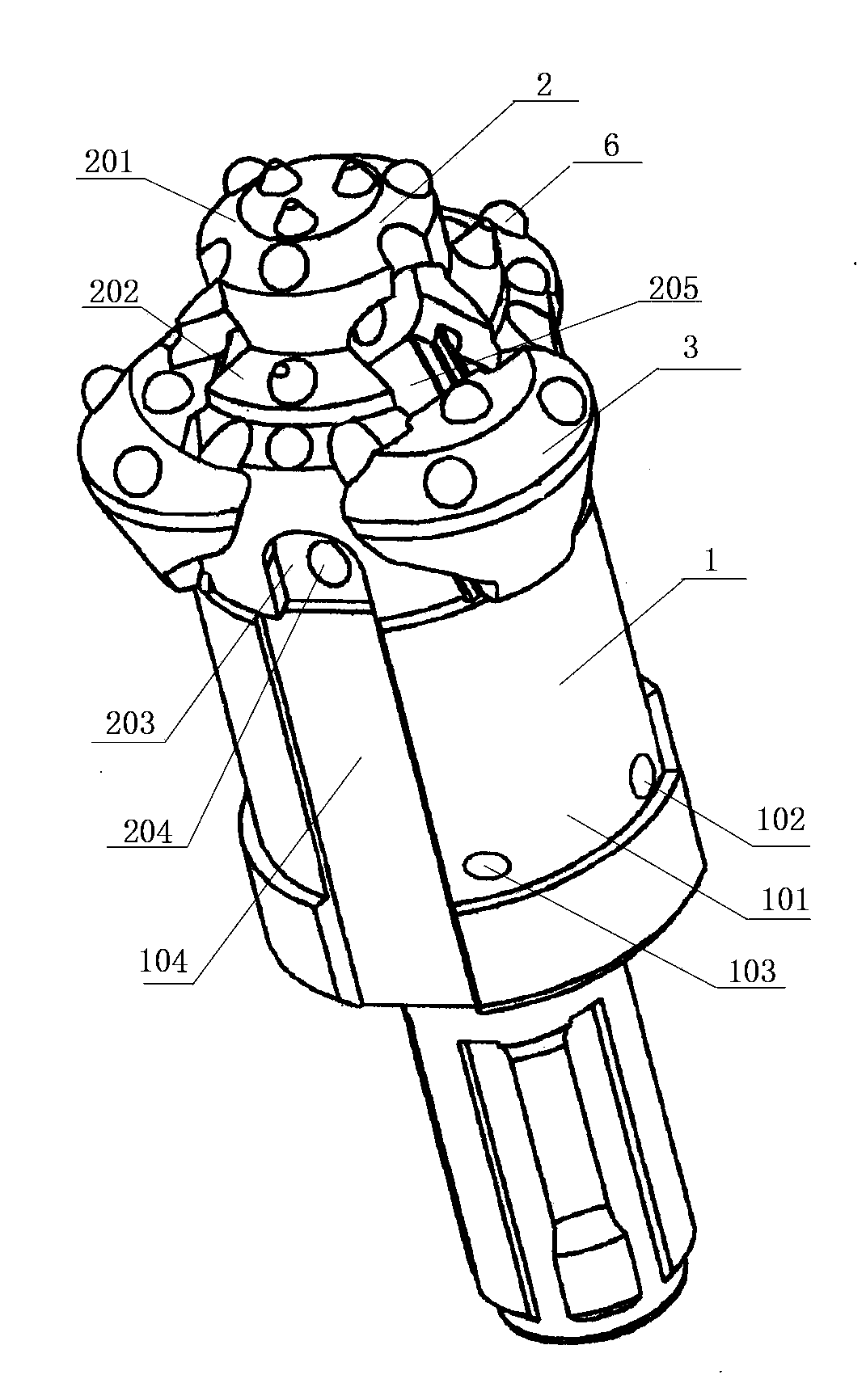

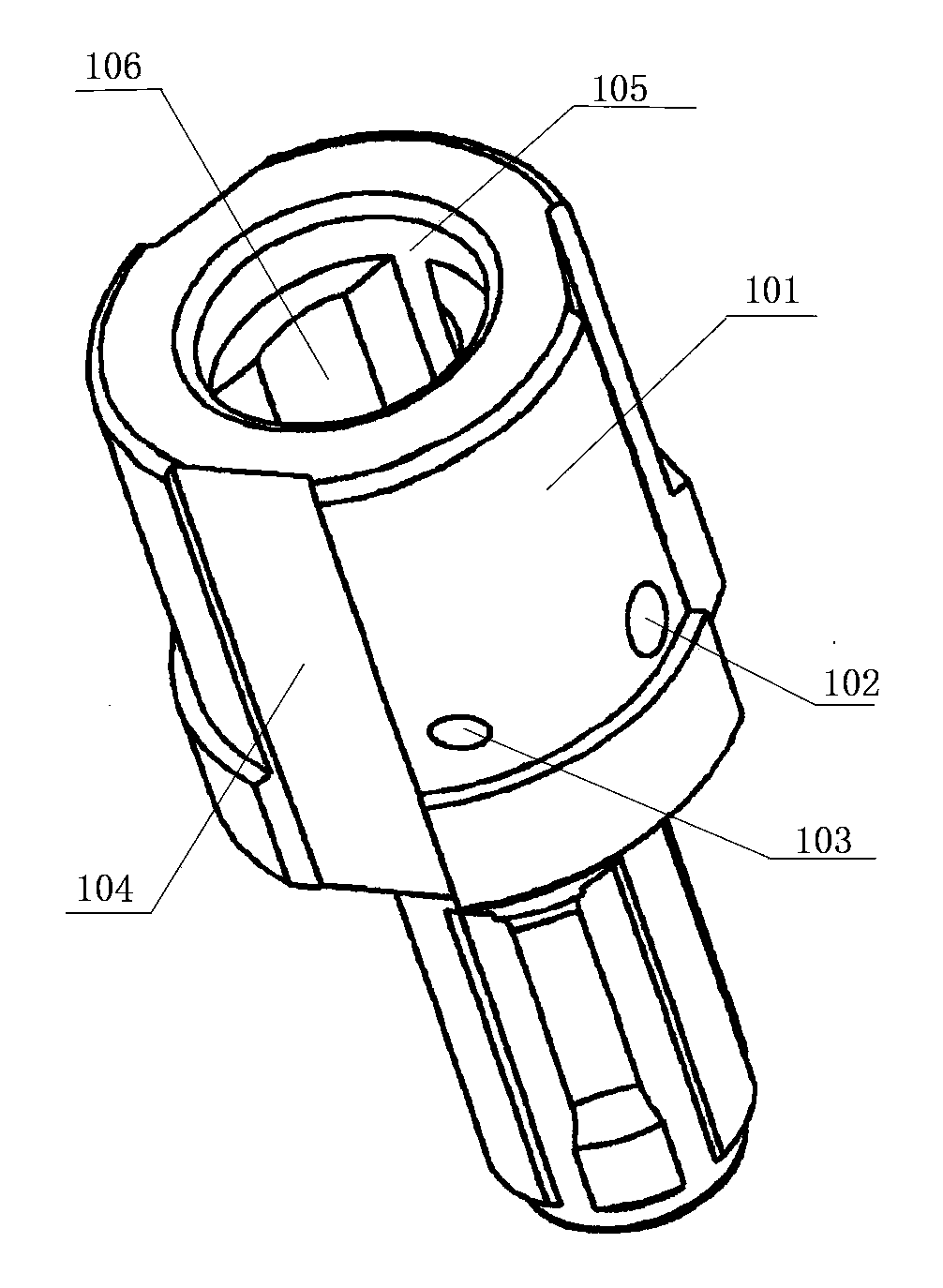

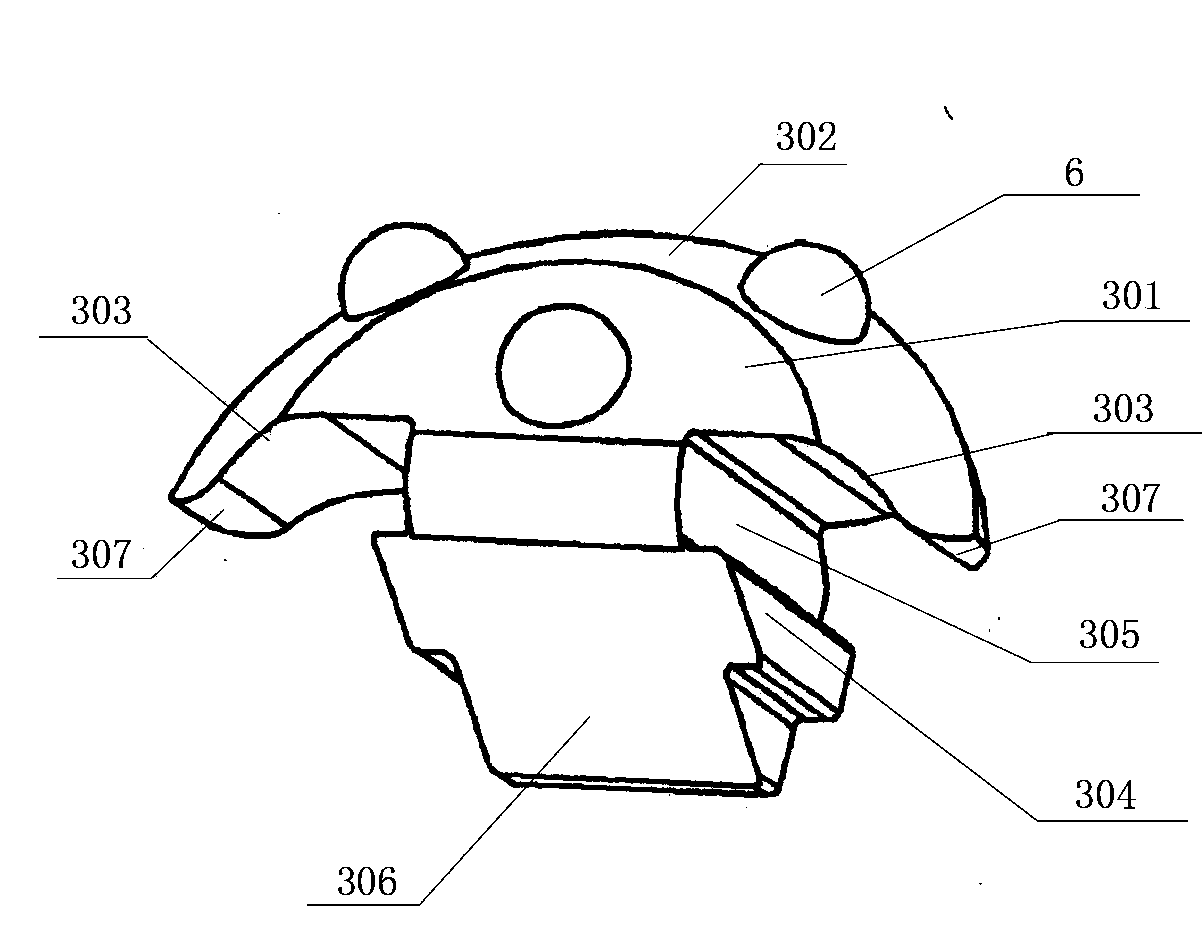

[0043] The central drill bit of the present invention includes a drill bit body 201 and a reaming drill piece 3. The drill bit body 201 has a front part, a middle part and a tail part along its central axis, and the front part, the middle part and the tail part are integrally structured. The front part of the drill bit body 201 is The middle part of the drill body 201 has an arrow-shaped structure. The diameter of the middle part of the drill body 201 is larger than that of the front part. At least two inclined grooves 208 are provided on the outer peripheral surface of the drill bit body 201 from the front part to the middle part. Groove, make chute 208 be the guide groove of T-shaped structure, this chute 208 can be 2, 3, 4, 5 or more, present embodiment preferably uses 2 chute 208, and 2 chute The grooves 208 are evenly distributed on the outer peripheral surface of the drill body 201 at intervals of 180° relative to the central axis, and any inclined groove 208 is matched w...

Embodiment 2

[0048] Embodiment 2 On the basis of Embodiment 1, the front part of the drill body 201 has a conical structure; the front part and the middle part of the drill body 201 have a truncated cone-shaped slope transition, and the number of the inclined grooves 208 is four, and the four inclined The grooves 208 are evenly distributed on the outer peripheral surface of the drill body 201 at intervals of 90° relative to the central axis, any chute 208 is matched with a reaming drill piece 3, and rectangular grooves and trapezoidal grooves are arranged on the two side walls of the chute 208 Or any one among the dovetail grooves, make the chute 208 a guide groove of T-shaped structure, the present embodiment selects the dovetail groove, and the bump body 304 cooperates with the guide groove, especially cooperates with the dovetail groove, so as to facilitate expansion Hole drill piece 3 slides in guide groove, and the afterbody of described drill bit body 201 is hexagonal cylinder, and th...

Embodiment 3

[0050] Such as image 3 and Figure 4 As shown, Embodiment 3 is based on Embodiment 1. In the center drill bit of the present invention, the front part of the drill body 201 is a circular boss structure, so that the front part of the drill body 201 presents a stepped multi-stage boss. In this example A three-stage boss structure is adopted, that is, a three-stage stepped structure. Of course, a two-stage boss structure, a four-stage boss structure, a five-stage boss structure, or more boss structures can be used according to actual needs. The diameter of the bevel taper is transitional, so that the diameter of the drill body 201 is the smallest from the front end, and then gradually increases, and the transition is made through the bevel taper. In this embodiment, there are three chute grooves 208, and the three chute grooves 208 are relatively The central axis is evenly distributed on the outer peripheral surface of the drill body 201 at intervals of 120°, any chute 208 is m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com