Pipeline oil heater

A heater and oil technology, used in fluid pressure actuation devices, fluid pressure actuation system components, mechanical equipment, etc. problem, to achieve the effect of high heating efficiency, fast heating speed and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

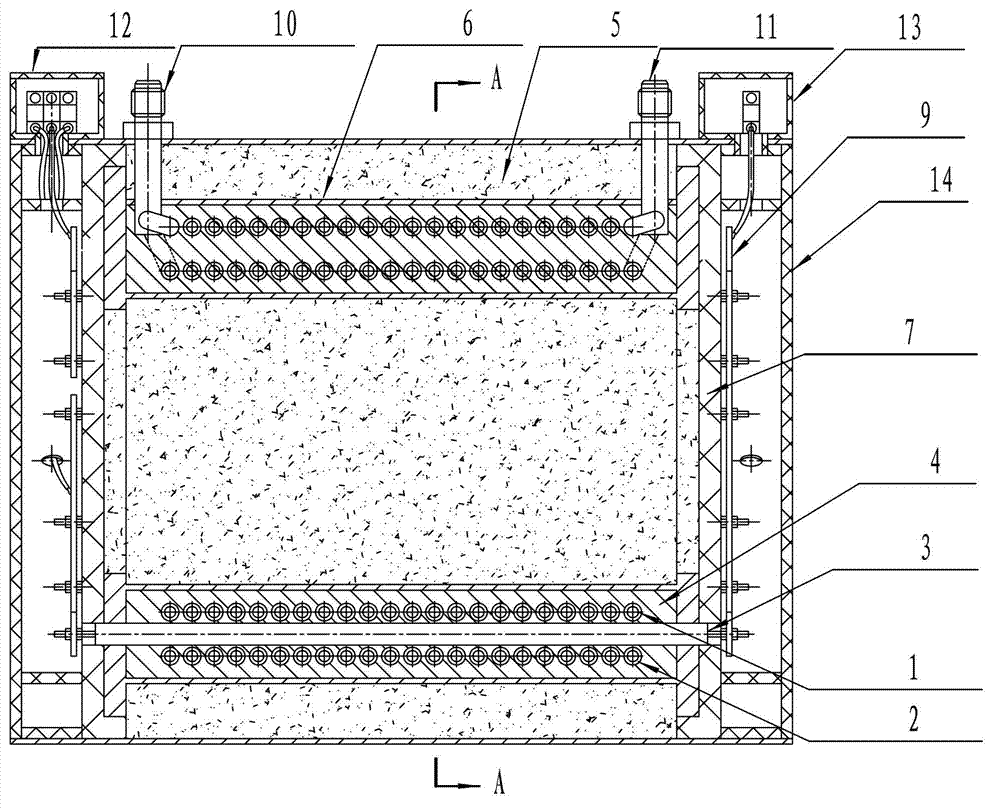

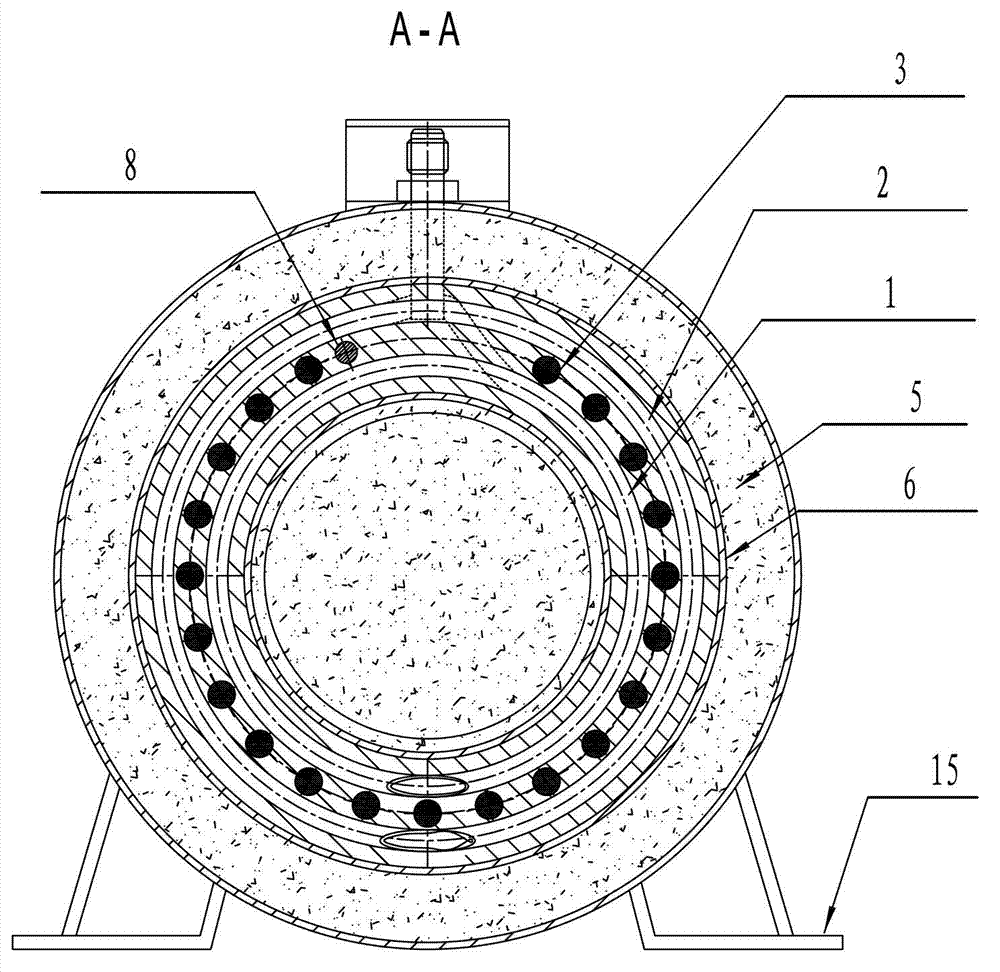

[0024] Pipeline oil heater, including hydraulic inner coil 1, hydraulic outer coil 2 and multiple electric heating tubes 3 arranged in parallel, the two ends of the hydraulic inner coil 1 and hydraulic outer coil 2 adopt oil inlet pipe joints 10 and the oil return pipe joint 11 are welded in parallel, and the hydraulic inner coil 1 and the hydraulic outer coil 2 welded in parallel are fixedly installed in the sandwich shell 6, and the aluminum alloy heating body 4 which constitutes an integral part is wrapped by aluminum alloy casting; Both the inner cavity and the outer part of the heating body are filled with thermal insulation material 5 .

[0025] A plurality of electric heating tubes 3 are distributed in the aluminum alloy cylindrical layer formed between the hydraulic inner coil 1 and the hydraulic outer coil 2 , and the connecting terminals of the electric heating tubes 3 are arranged at both ends of the aluminum alloy cylindrical layer. In addition, a temperature senso...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap