Novel gearbox assembly of gear mini-tiller

A technology of gearbox body and micro-tiller, applied in the direction of gear transmission, belt/chain/gear, mechanical equipment, etc., can solve the problems of heavy gearbox, many gears, complex structure, etc. The effect of few gears and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

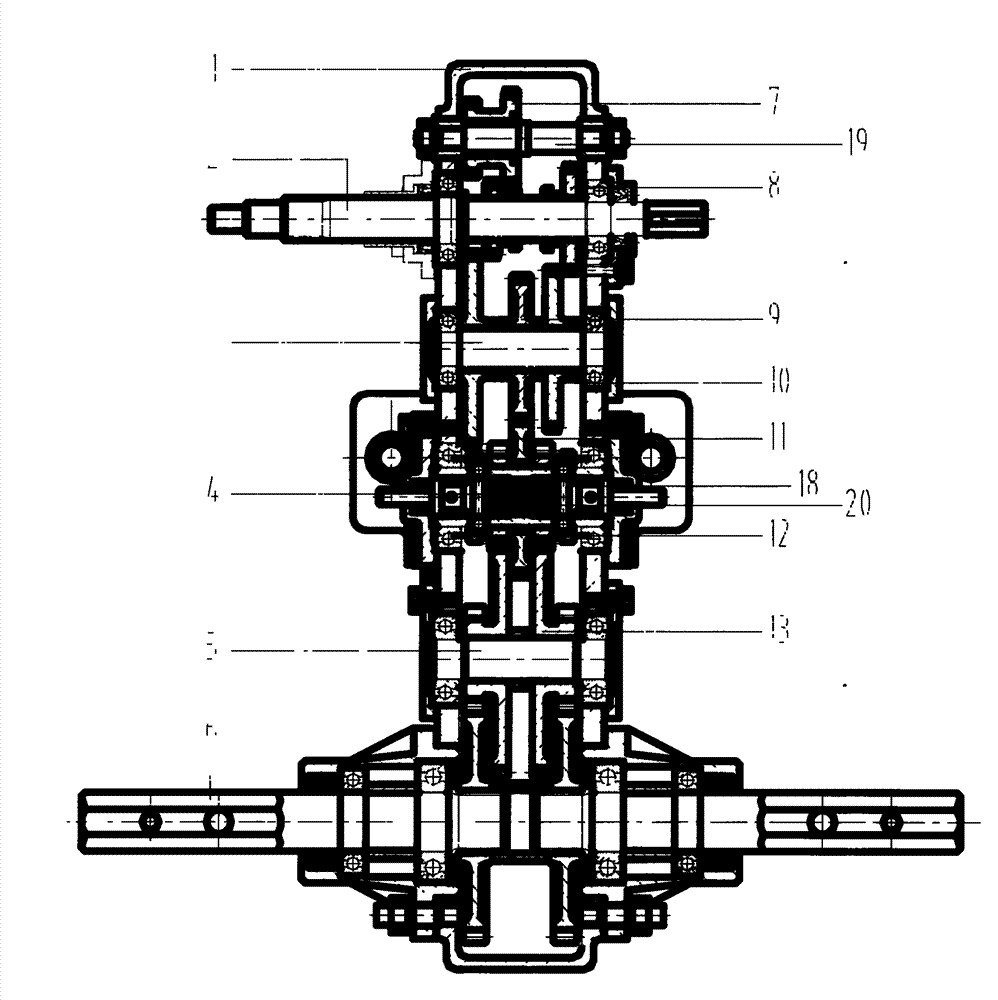

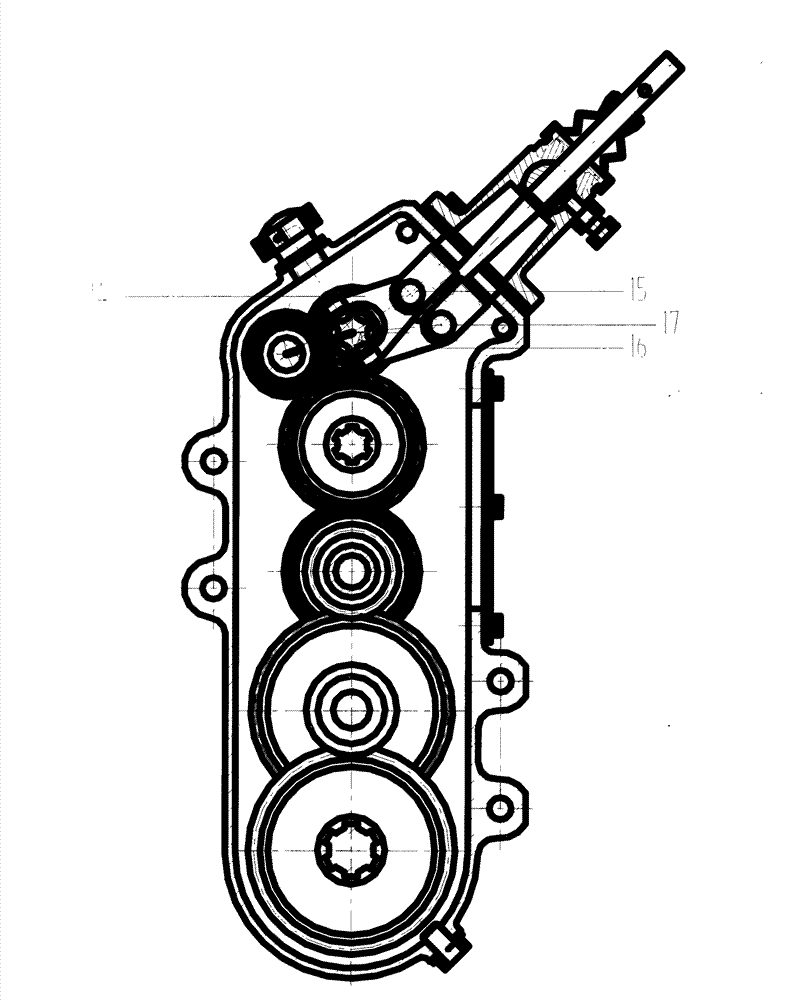

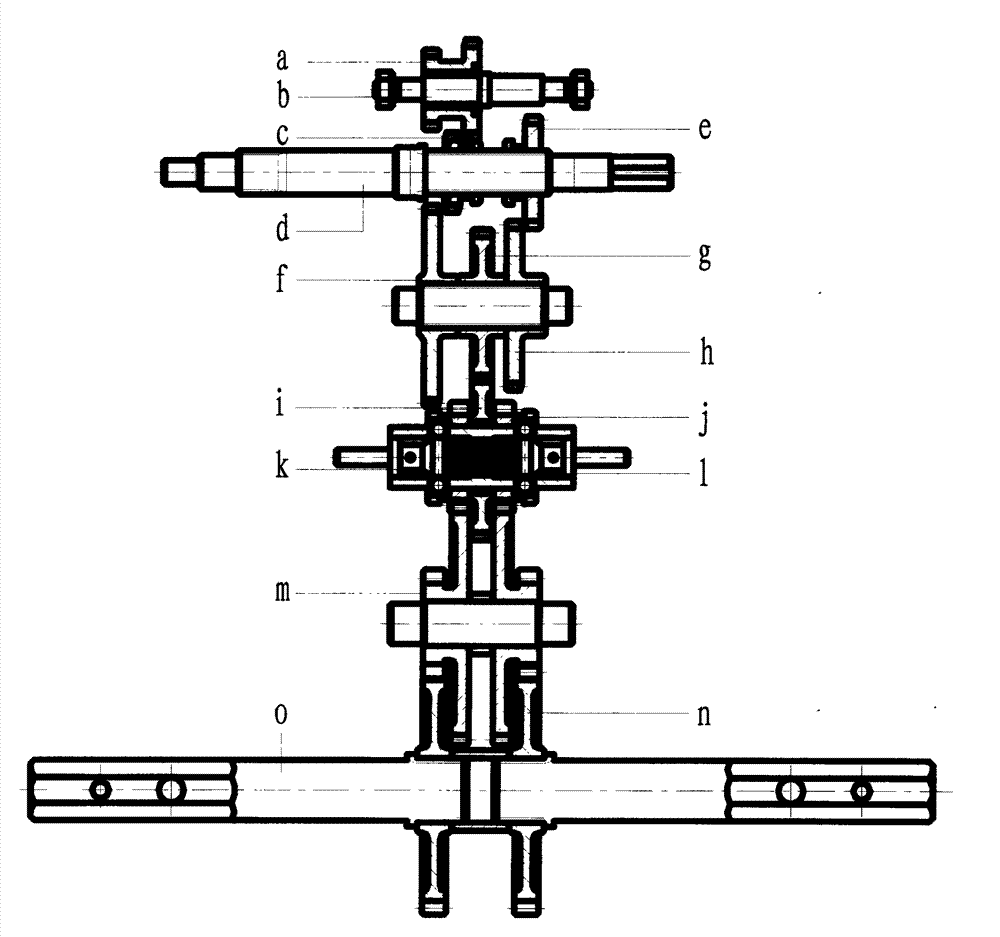

[0015] The preferred embodiment of the present invention is such, with reference to accompanying drawing, in order to overcome the defects such as the gearbox body assembly self weight of the general tiller on the market is relatively large, the structure is relatively complicated, gears are used more, and the cost is relatively high. The technical problems solved by the gearbox body assembly of the 1Z21T tiller of the present invention are: light weight, simple structure, less gears and relatively low cost. Its structure mainly includes gearbox body, I shaft, II shaft, steering shaft, IV shaft, drive shaft, reverse gear, I reverse gear, I shaft II gear, II shaft intermediate gear, II shaft I gear, II shaft Shaft II gear, steering gear, steering pinion, IV shaft dual gear, driving gear, I reverse gear fork, I reverse gear fork shaft, II gear fork, II gear fork shaft, steering finale, reverse Gear shaft, steering spring; the power of the diesel engine is transmitted to the I sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com