Buffer air chamber structure of vehicle compressed natural gas (CNG) pressure reducing valve

A natural gas and pressure reducing valve technology, applied in the valve operation/release device, valve details, valve device and other directions, can solve the problems of high technical requirements, leakage, inability to reuse, etc., to achieve sufficient forward momentum, increased flow, The effect of easy disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

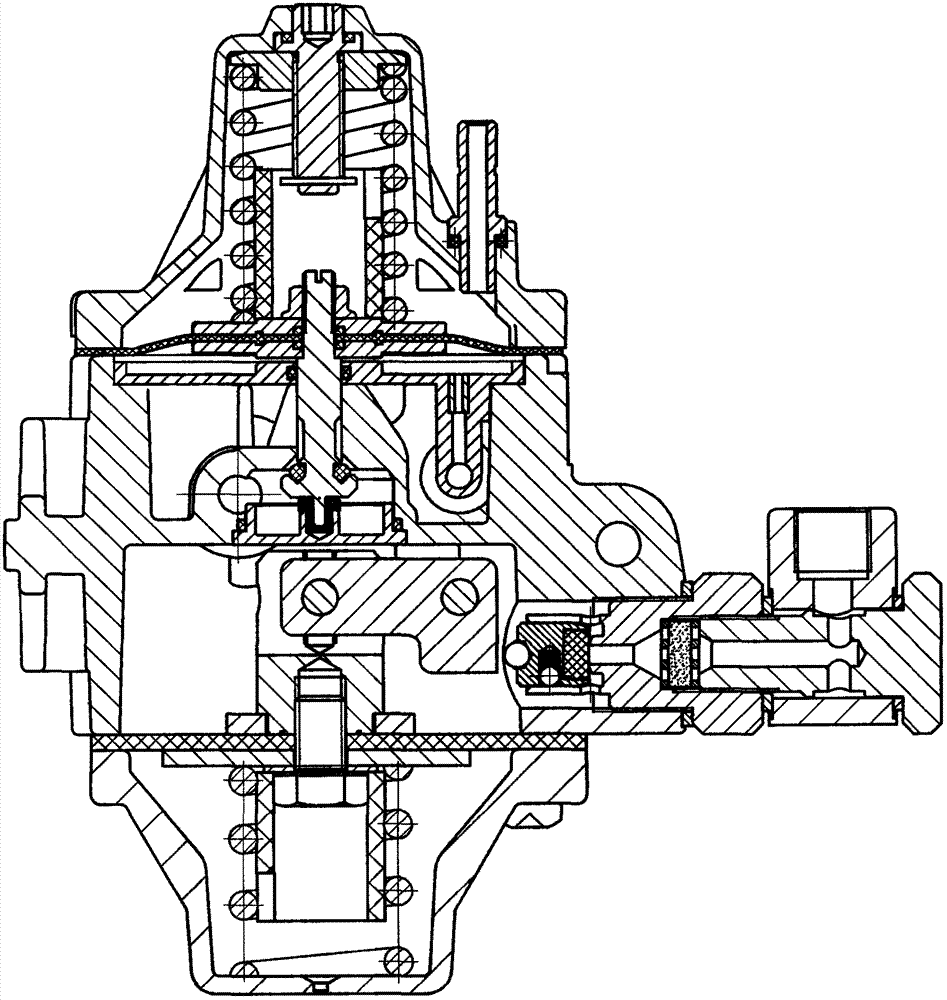

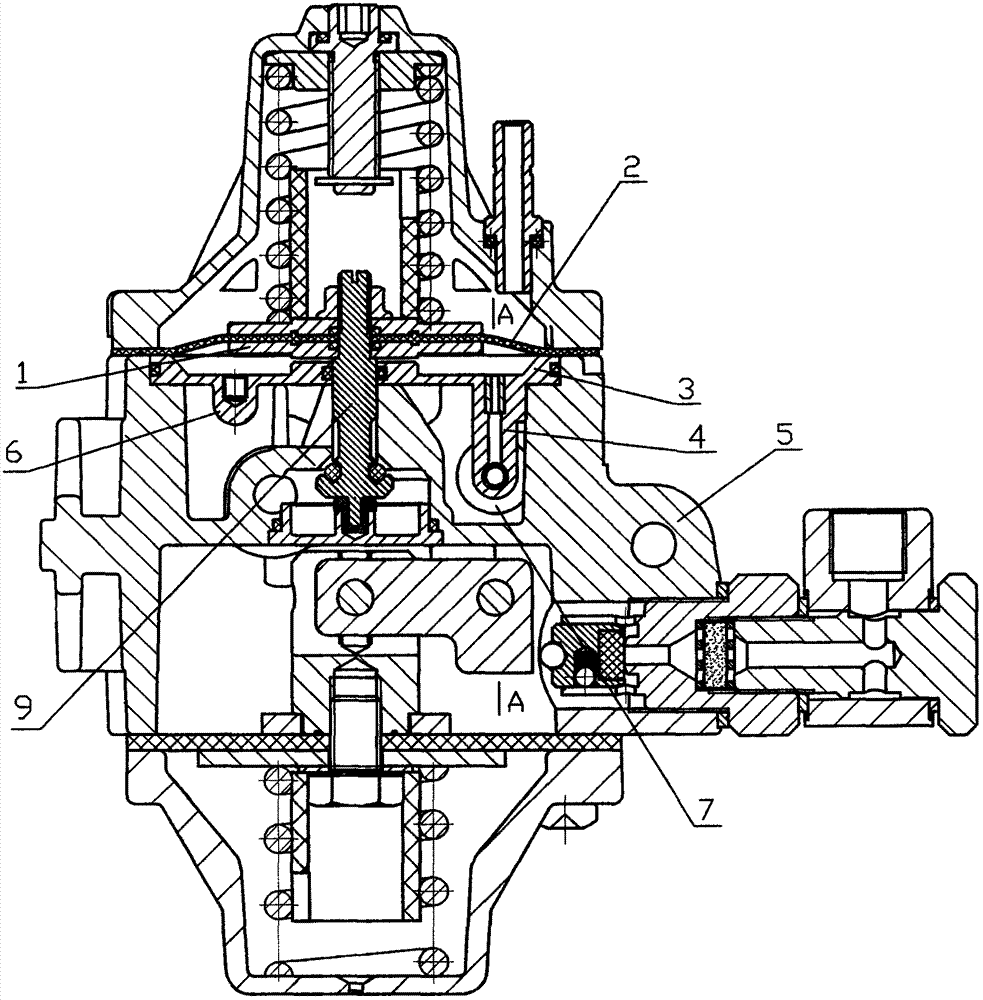

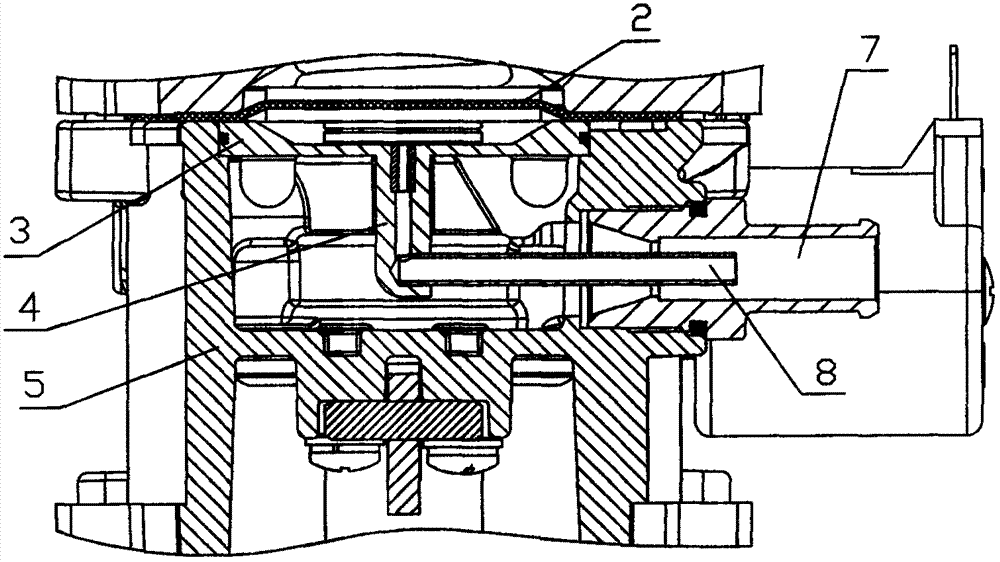

[0013] The present invention includes: isolating the ring disc 3, the upper elastic diaphragm 2, the lower spring gasket 1, the top membrane rod 9, the annular step groove and the air outlet 7 of the middle housing 5, and is characterized in that: the isolation ring disc 3 and the The annular step groove of the middle shell 5 is of the same height, and the outer circle of the isolation ring disc 3 is provided with a central circumferential groove, and a rubber sealing ring is fitted in the circumferential groove, and the outer circle of the isolation ring disc 3 is dynamically fit and fitted on the In the annular step groove of the middle shell 5, a ring groove is arranged on the upper surface of the isolation ring disc 3, and the top film rod 9 elastically fits through the central hole of the isolation ring disc 3 to fit a fixed rubber sealing ring; the isolation ring disc 3. The inner circle of the L-shaped orifice tube 4 extended in one piece is fixedly fitted with a horizon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com