Automatic temperature control ultralow temperature semiconductor refrigerator and automatic temperature control method thereof

A semiconductor and controller technology, applied in the field of low-temperature or ultra-low temperature refrigeration systems, can solve the problems of inconvenient technical operation, high cost, complex system structure, etc., and achieve the effect of avoiding heat accumulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

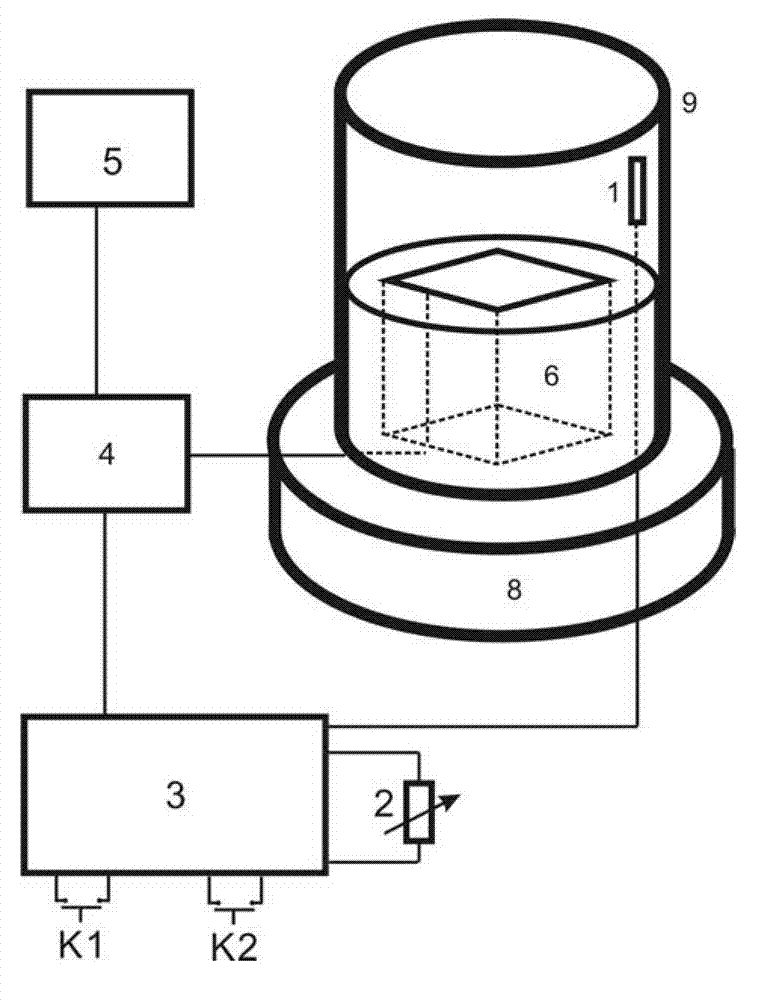

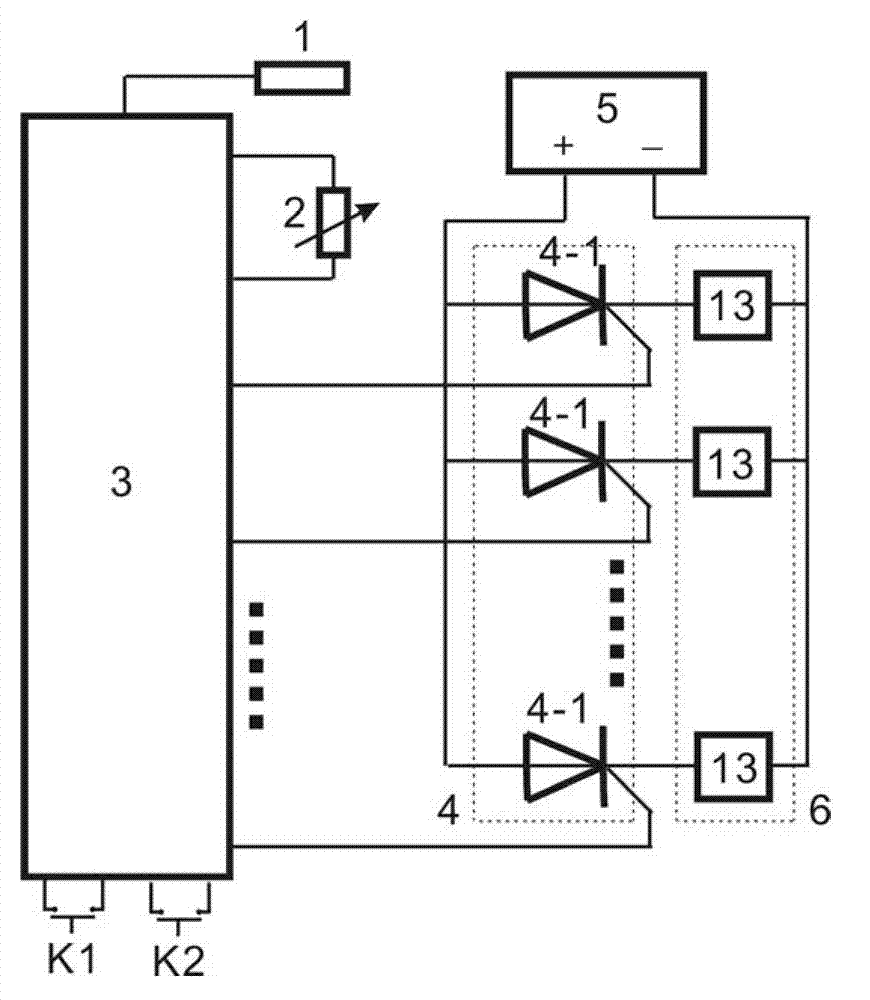

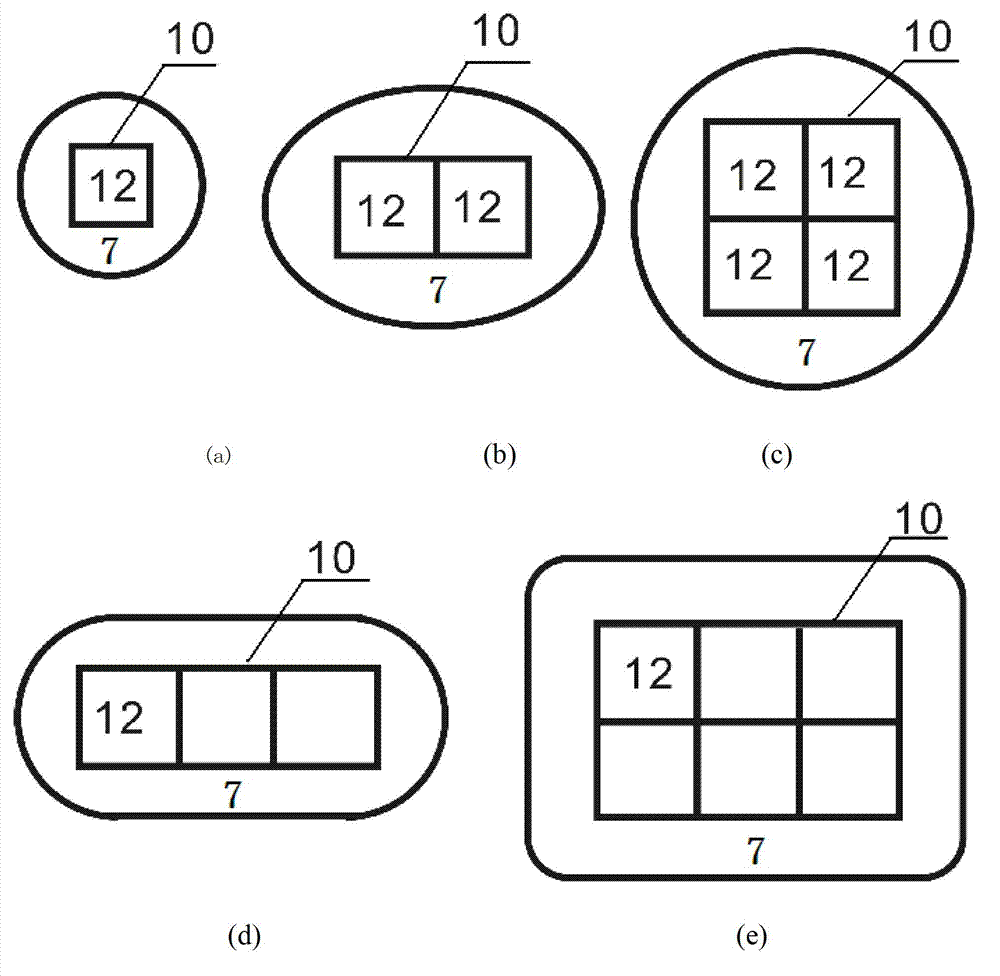

[0131] Such as figure 1 Shown, the embodiment of the ultra-low temperature semiconductor refrigerator of automatic temperature control of the present invention adopts such as figure 1 In the structure shown, the semiconductor refrigeration stack 6, the optical fiber coiled column, the heat insulating shell 9, and the radiator 8 are all columnar structures.

[0132] Insulation shell 9 adopts such as Figure 6 The double-layer vacuum wall stainless steel barrel structure shown is 16cm in outer diameter, 13cm in inner diameter, 30cm in barrel height, 28cm in inner height, 1.5mm in thickness of stainless steel plate, vacuum pumped between walls for heat insulation, and all edges are rounded.

[0133] Semiconductor refrigeration stack 6 adopts figure 1 As shown in the cylindrical structure, the semiconductor cooling chip 13 adopts TEC1-12712, the maximum voltage is 15.4V, the maximum current is 12A, the outer diameter is 62*62*4mm, and the enthusiasm 14 adopts the copper block of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com