Test method of rock aging deterioration process

A test method and technology for rock samples, which are applied in the direction of using sonic/ultrasonic/infrasonic waves to analyze solids, etc., can solve the problems of inability to accurately and effectively test the aging deterioration characteristics of rocks, and achieve the effect of accurate test results.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

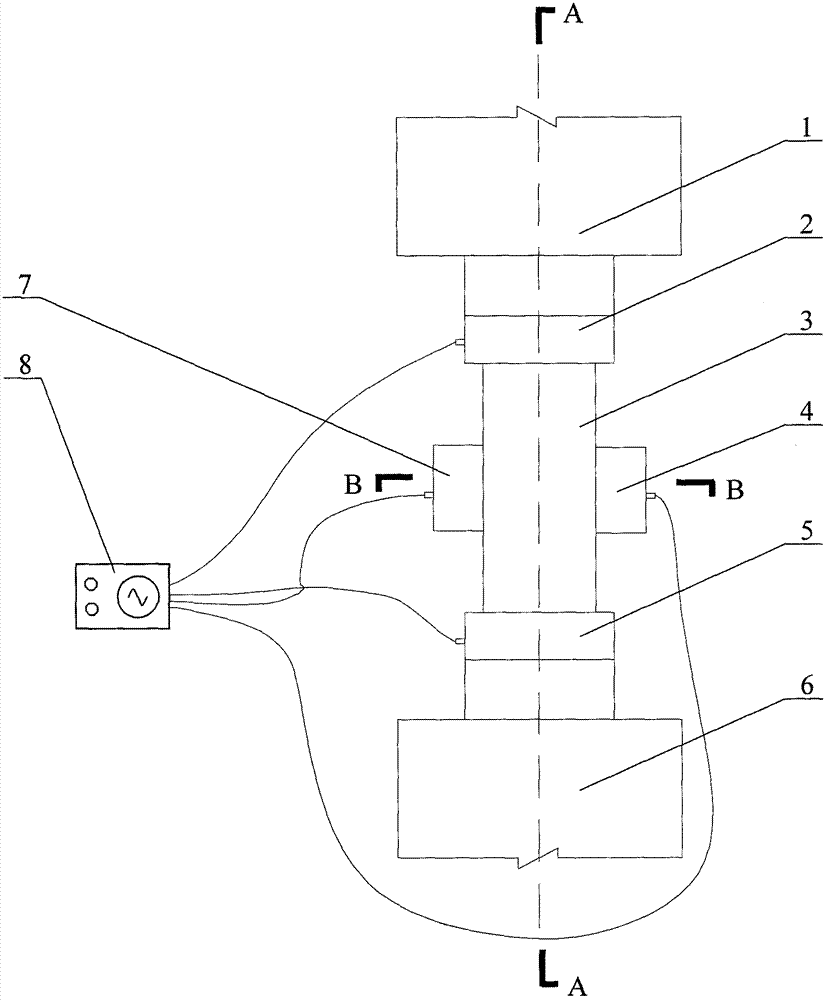

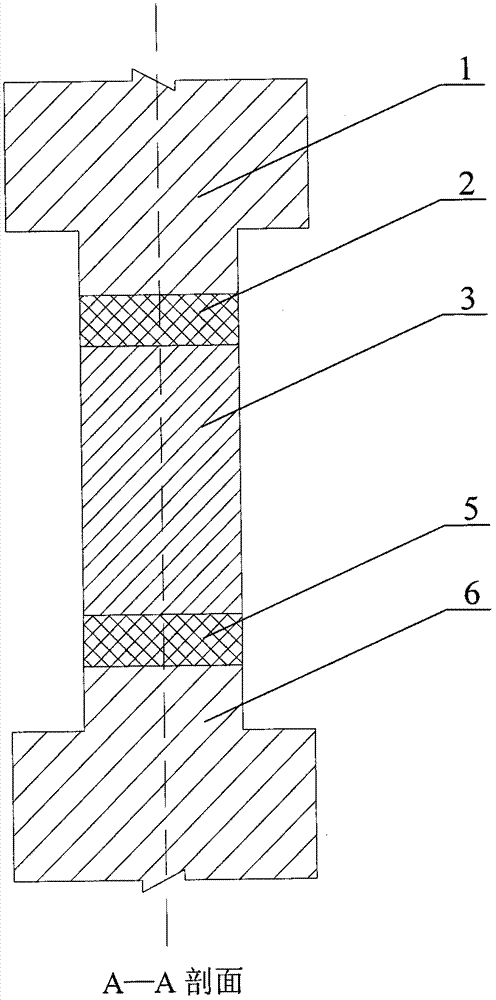

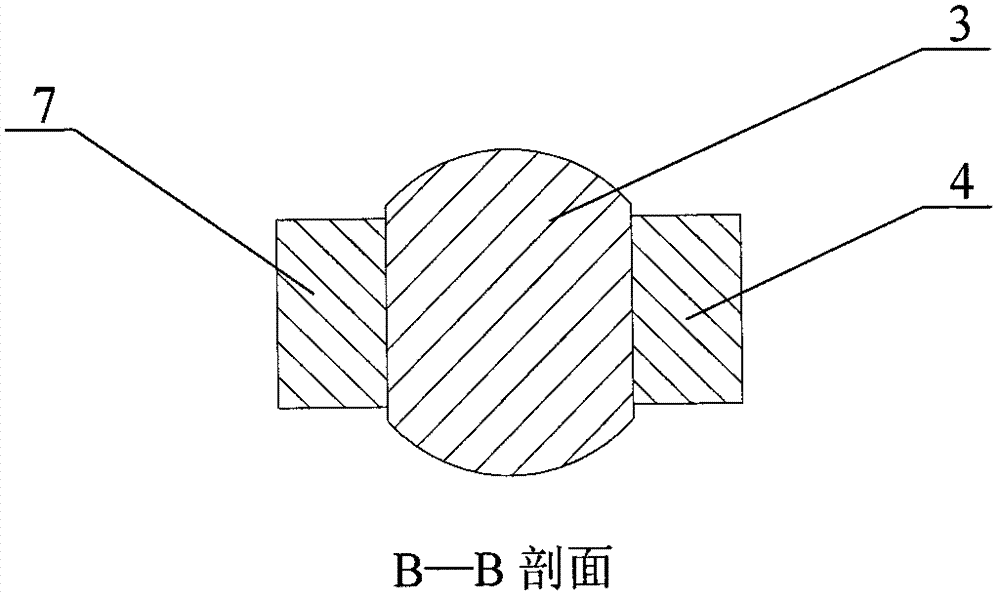

[0053] (1) After the diameters of the pressure-bearing acoustic wave transmitting probe 2 and the pressure-bearing sound wave receiving probe 5 are known to be 80 mm, the rock block is processed into a cylindrical rock sample with a diameter of 70 mm and a height of 140 mm, and then After the diameter of the acoustic wave transmitting probe 4 and the non-pressurized acoustic wave receiving probe 7 is 10 mm, two symmetrical side planes with a width of 10 mm and parallel to the axis of the cylinder are ground on both sides of the cylinder rock sample to obtain rock sample 3, processing and making rock sample 3 totally ten.

[0054] (2) Take five of the batch of rock samples 3 and carry out the instantaneous uniaxial compression test, calculate and obtain the average instantaneous value of the rock samples 3 to be subjected to the aging test to be 125MPa, and measure the average Poisson's ratio ν of the rock samples 3 =0.24 and average density ρ=2680kg / m 3 .

[0055] (3) After ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com