Testing type high-temperature molten salt loop

A salt-melting and circuit technology, applied in the field of solar thermal power generation heat storage circuit, can solve the problems of general steam quality and restricting the operation efficiency of back-end generator sets.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

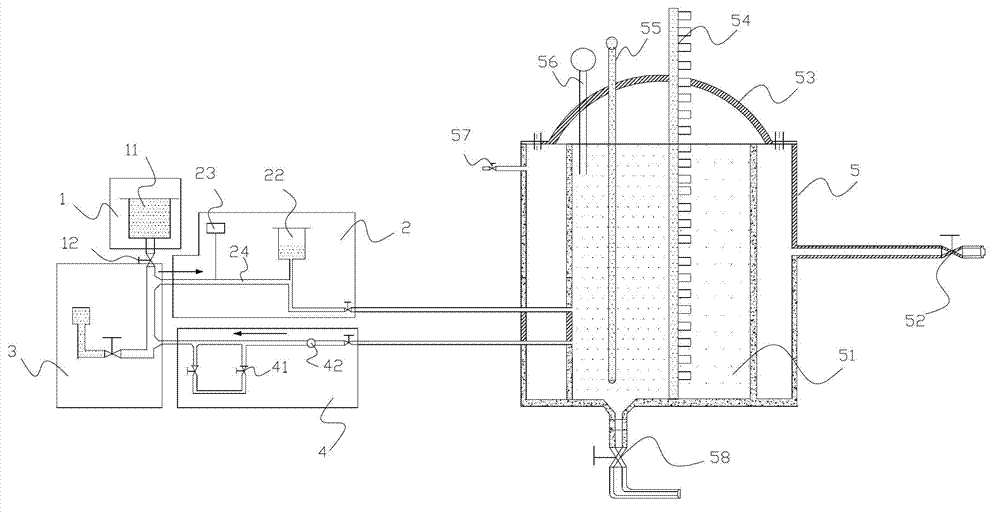

[0015] like figure 1 As shown, a test-type high-temperature molten salt loop includes five parts,

[0016] The first part is the molten salt box 1, the molten salt box 1 is mainly composed of the incubator 11, and the resistance wire is wound on the outside, and the molten salt is heated by electric current to make it melt, and then flows into the circuit through the high temperature baffle valve 12, with temperature control system to control the heating temperature of molten salt;

[0017] The second part is the molten salt heating export section 2. The molten salt heating export section 2 is composed of a molten salt circuit 24, a high temperature flow meter 23, and an expansion tank 22. The high temperature flow meter 23 controls the flow ra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com