Method for positioning rotor rubbing sound emission source by applying time delay estimation

A technology of time delay estimation and rubbing sound, which is used in positioning, measuring devices, instruments, etc., can solve the problem of not considering signal attenuation, error, etc., to improve the accuracy of time delay estimation, improve performance, and reduce steady-state imbalance. amount of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The technical solution of the present invention will be further elaborated below in conjunction with the accompanying drawings and examples.

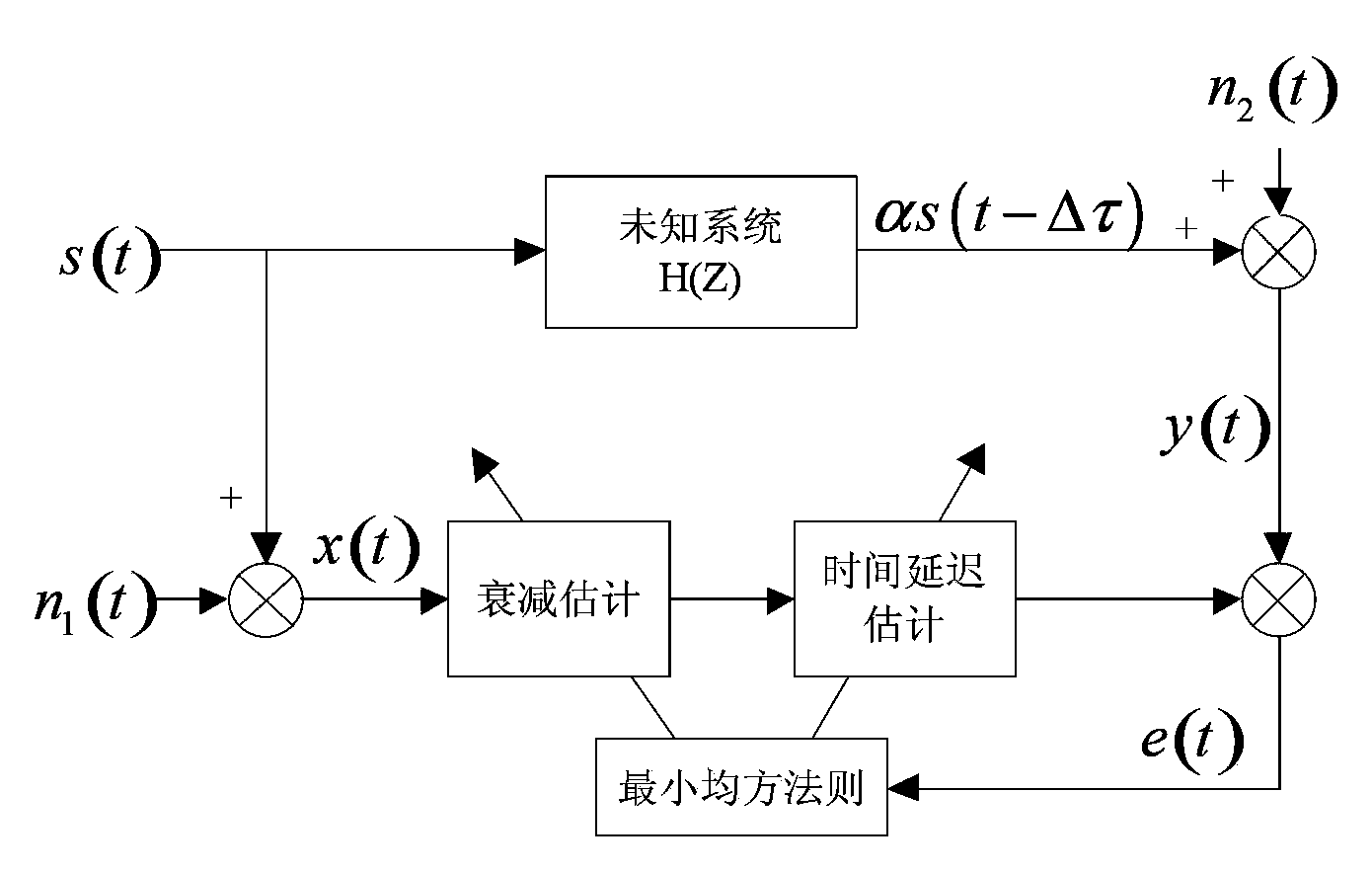

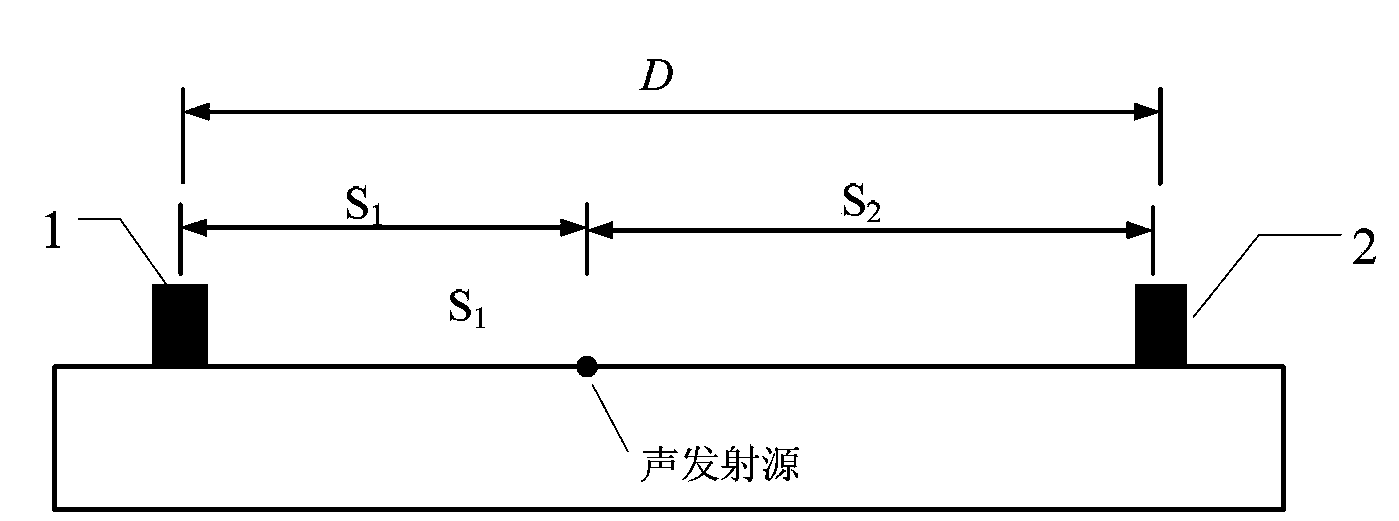

[0032] Such as figure 1 with figure 2 As shown, a method for locating the rotor rubbing acoustic emission source using time delay estimation of the present invention includes the following steps:

[0033] 10): Establish a one-dimensional linear positioning model: set two sensors, the first sensor 1 and the second sensor 2, on the rubbing waveguide plate of the rotor test bench, the rotor rubbing source is located between the two sensors, and the rotor rubbing The source and the two sensors are located on the same straight line. After the rotor rubs, an acoustic emission signal is generated, which is received by the two sensors. The acoustic emission signal is accompanied by attenuation and noise interference during propagation.

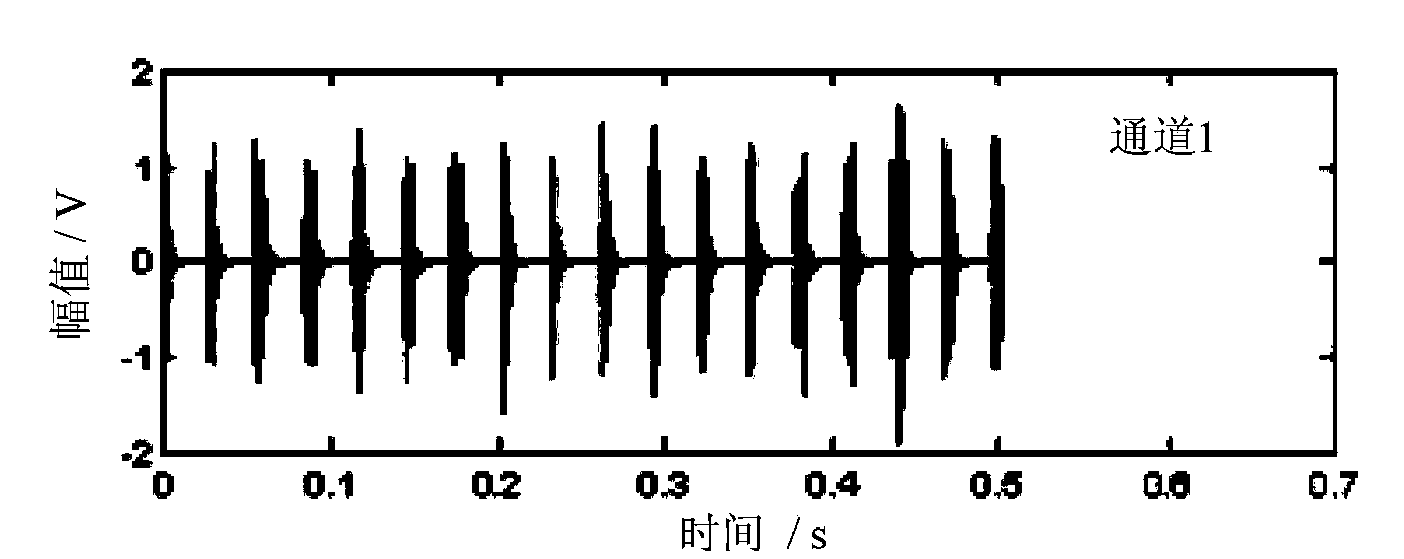

[0034] In step 10), the rotor rubbing acoustic emission signal is obtained by obtaining the rotor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com