Method for detecting working states and diagnosing faults for large shield

A working state and fault diagnosis technology, applied in the direction of instruments, computer control, simulators, etc., can solve the problems that maintenance personnel are difficult to find fault points in time, the timely repair rate is low, and it is difficult to find fault points and fault causes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] Preferred embodiments of the present invention are described below in conjunction with the accompanying drawings.

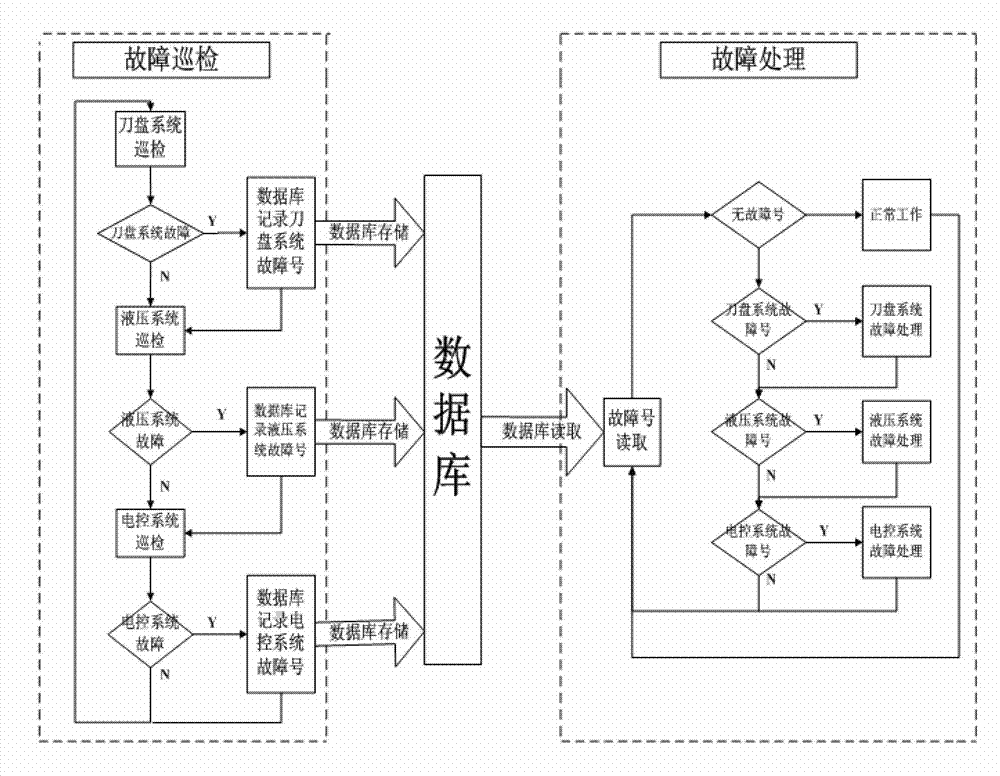

[0010] Please refer to figure 1 , the working state detection and fault diagnosis method of the large-scale shield tunneling machine in this embodiment includes two major tasks of fault inspection and fault handling. The two tasks are processed independently in terms of time, and information exchange is performed through the database.

[0011] In this embodiment, the fault number of the cutter head control system is set to 100, the fault number of the hydraulic system is 200, and the fault number of the electric control system is 300.

[0012] The fault inspection task detects damage to the tool in the cutter head system during the inspection process, and the system fault number 100 is generated and stored in the database. The fault processing task reads the fault number 100 from the corresponding fault number storage location in the database. The working...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com