Hysteresis loss improvement and eddy current on-line monitoring method for excitation transformer

An excitation transformer, hysteresis loss technology, applied in the direction of transformer/inductor core, transformer/inductor components, preventing/reducing unwanted electrical/magnetic effects, etc., can solve hysteresis loss and eddy current loss, etc. problems, to achieve the effect of reducing eddy current loss, reducing eddy current loss, and creating long-term economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The method of the present invention will be described in detail below in conjunction with the accompanying drawings.

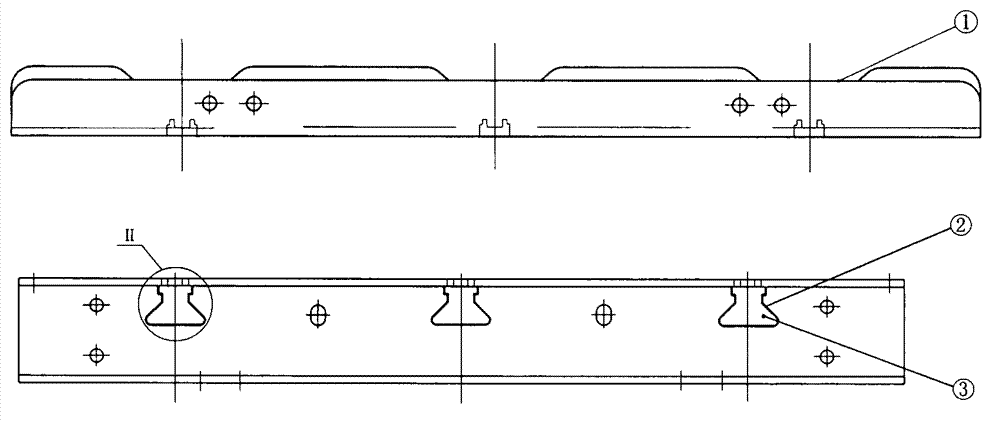

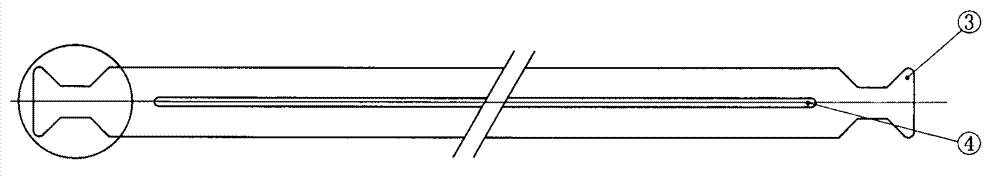

[0018] like figure 1 Shown is the non-excitation clamping part of the transformer, including non-excitation high-strength steel plate (1), polymer insulating skirt (2) and high magnetic permeability pull plate (3).

[0019] The non-excitation high-strength steel plate (1) is placed on the outer layer as the clamping part of the transformer, a plurality of polymer insulating skirts (2) are embedded in the non-excitation high-strength steel plate (1), and the high magnetic permeability pull plate (3) is located Between the transformer and the non-excitation high-strength steel plate (1).

[0020] Among them, the non-excitation high-strength steel plate (1) is made of non-excitation material, which is formed by laser cutting, opening, and bending at one time, without burrs and solder joints, and can effectively reduce eddy current loss; The polymer insul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com