Automatic production system for inductance coil

A production system and inductance coil technology, applied in the field of inductance coil automatic production system, can solve the problems of poor performance, high efficiency cost, unstable inductance coil product quality, etc., and achieve the effect of reducing production cost and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

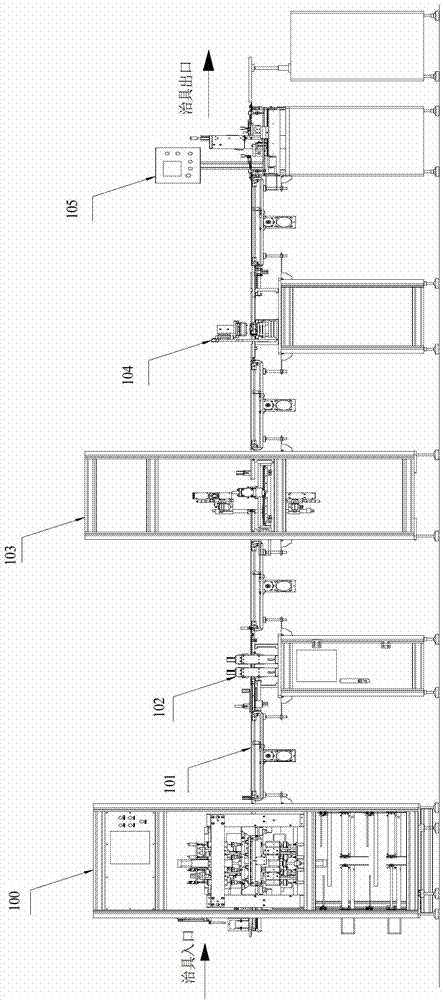

[0013] Please refer to figure 1 , figure 1 Shown is a schematic structural diagram of an automatic production system for inductance coils in a preferred embodiment of the present invention. The present invention proposes an automatic production system for inductance coils, including: a four-axis winding machine 100, an automatic feeding bending machine 102, an automatic feeding upper and lower laser paint stripping machine 103, an automatic feeding electrode sheet machine 104, and an automatic feeding cover plate The resistance spot welding machine 105 is connected through the jig conveyor belt 101 in turn.

[0014] According to a preferred embodiment of the present invention, the four-axis winding machine 100 includes four jig winding mechanisms for placing four jigs and coil winding, and the automatic feeding bending machine 102 includes coils twice Bending device, the automatic feeding up and down laser paint stripping machine 103 includes a reciprocating movement control...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com