Oolong tea extract

A technology of oolong tea beverage and composition, applied in tea extraction, tea, food science, etc., can solve the problems of aroma reduction, aroma components reduction, disappearance, etc., and achieve the effect of maintaining and enhancing aroma

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

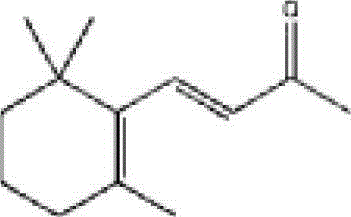

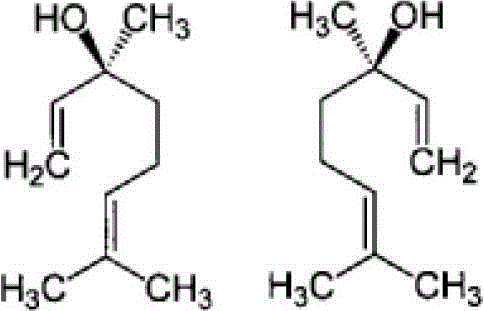

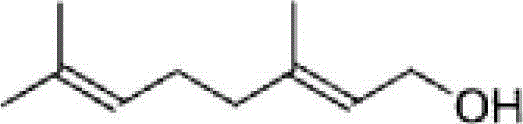

Image

Examples

Embodiment 1

[0044] Embodiment 1: the manufacture of oolong tea extract

[0045] (1) Turbidity analysis

[0046] 100 g of oolong tea (Fujian Province Sezhong) was extracted with 1500 mL of ion-exchanged water at 90° C. for 15 minutes. After the resulting extract was roughly filtered with a 150-mesh metal filter, it was cooled to below 30°C to obtain the first oolong tea extract (with a Brix of 3.0. Measured with a digital display refractometer RX-5000α made by ATAGO Corporation. Below, the relevant Brix is measured using the digital refractometer.). To this oolong tea extract, a glycoside decomposing enzyme (β-glucosidase) preparation "Amano" (manufactured by Amano Enzyme Co., Ltd.) (β-glucosidase 13%, Excipient 87% compound. Source: Penicillium Multicolor, potency: β-glucosidase potency 800 U / g or more), and perform enzyme treatment in a constant temperature room at 45°C for 3 hours. After the enzyme treatment, heat at 90° C. for 30 minutes to inactivate the enzyme, cool to below 30°...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com