Wheat ear-grain stripping structure for harvester and harvester with same

A technology for harvesters and wheat ear grains, which is applied to harvesters, agricultural machinery and implements, and applications. It can solve the problems of bulky and bulky harvesters, splashing of rice and wheat grains, and large diameter of the drum. It achieves light weight, The effect of low cost and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

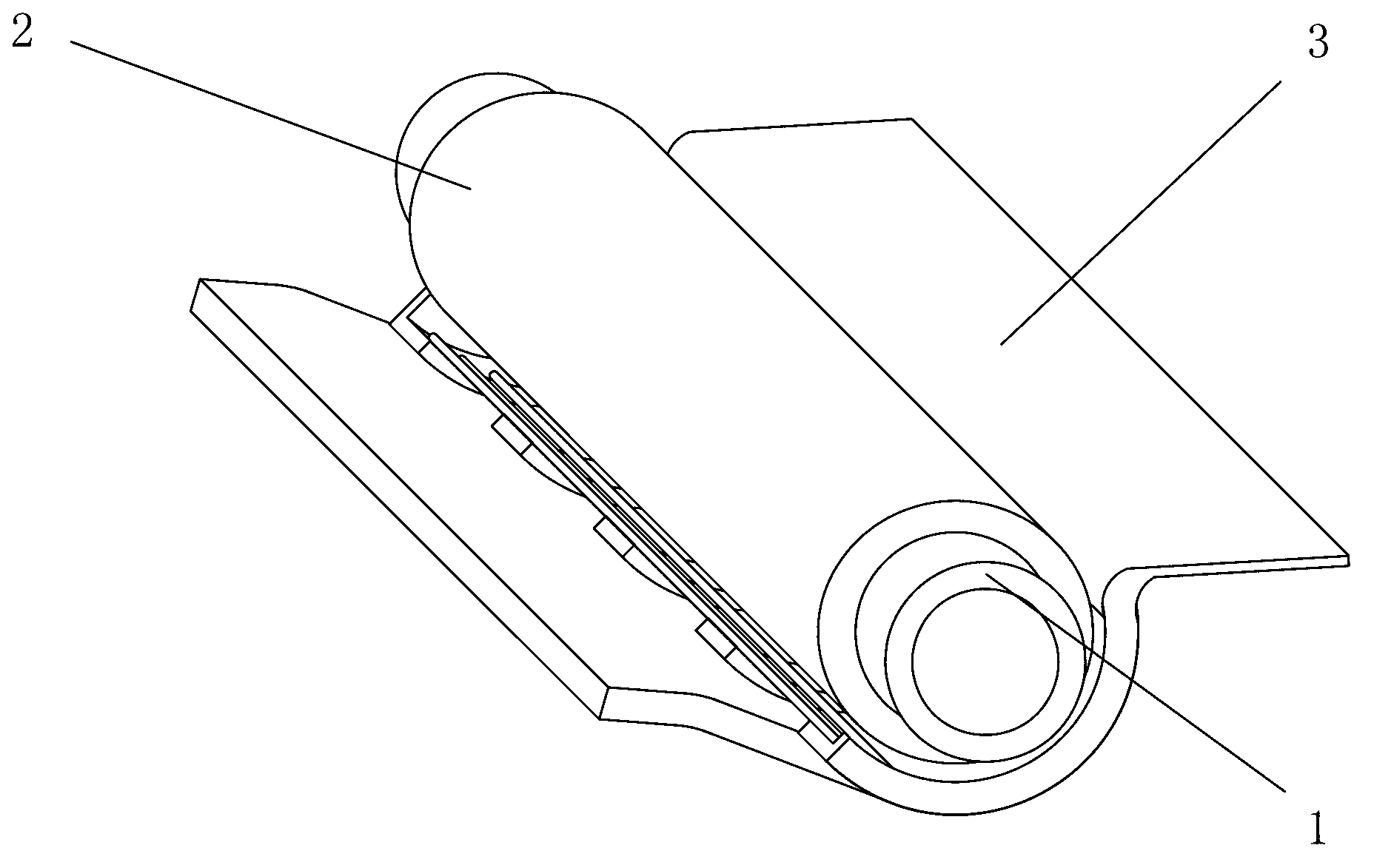

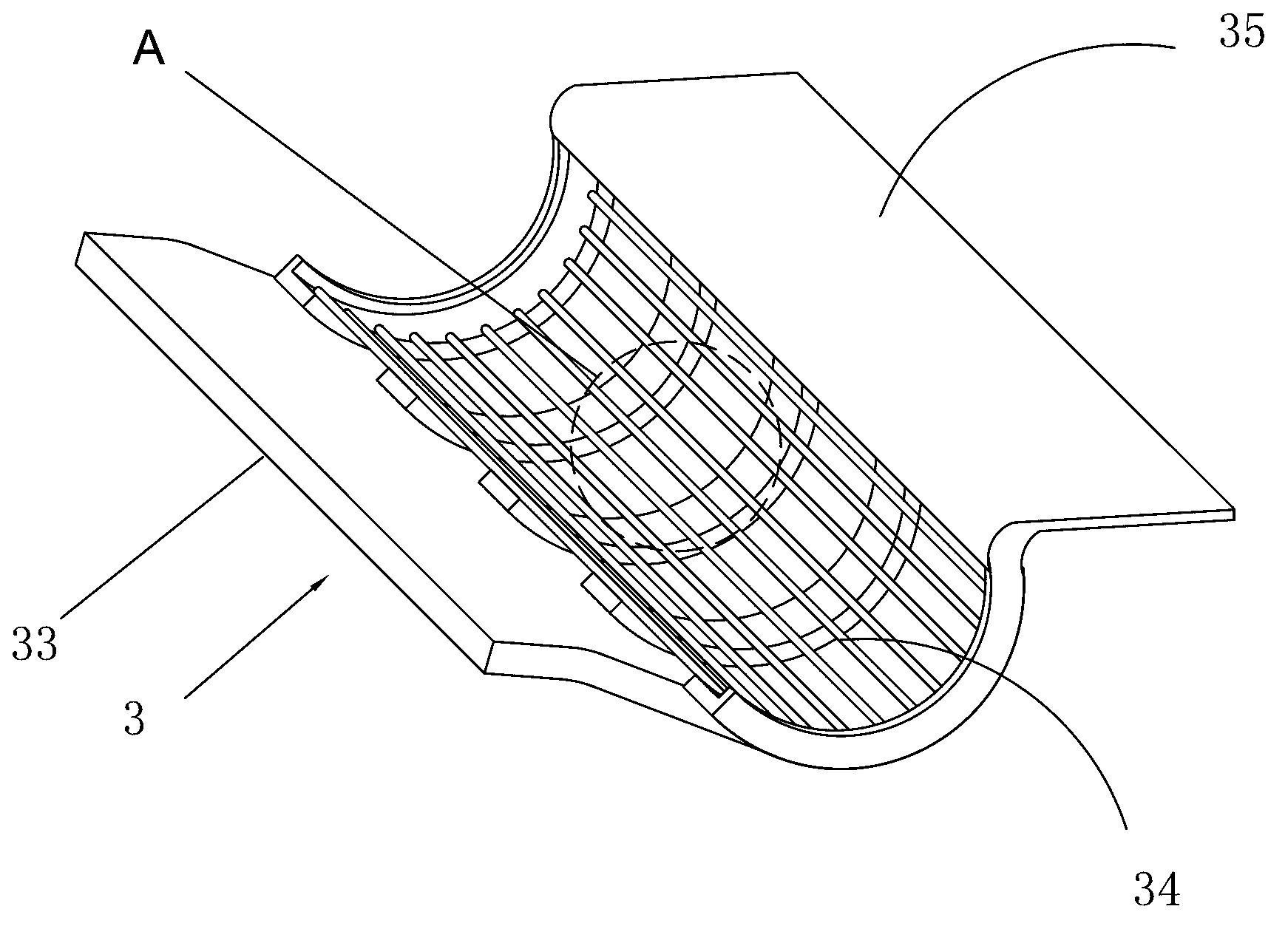

[0028] like figure 1 , 5 Shown, the stripping structure of the rice and wheat ear grains that is used for harvester of the present invention is installed on the front portion of harvester, and this structure comprises the rotating drum 1 that is horizontally arranged on the frame, and the rotating shaft of rotating drum 1 is arranged on the harvester The driving device is connected, and when working, driven by the driving device, the drum 1 rotates from back to front.

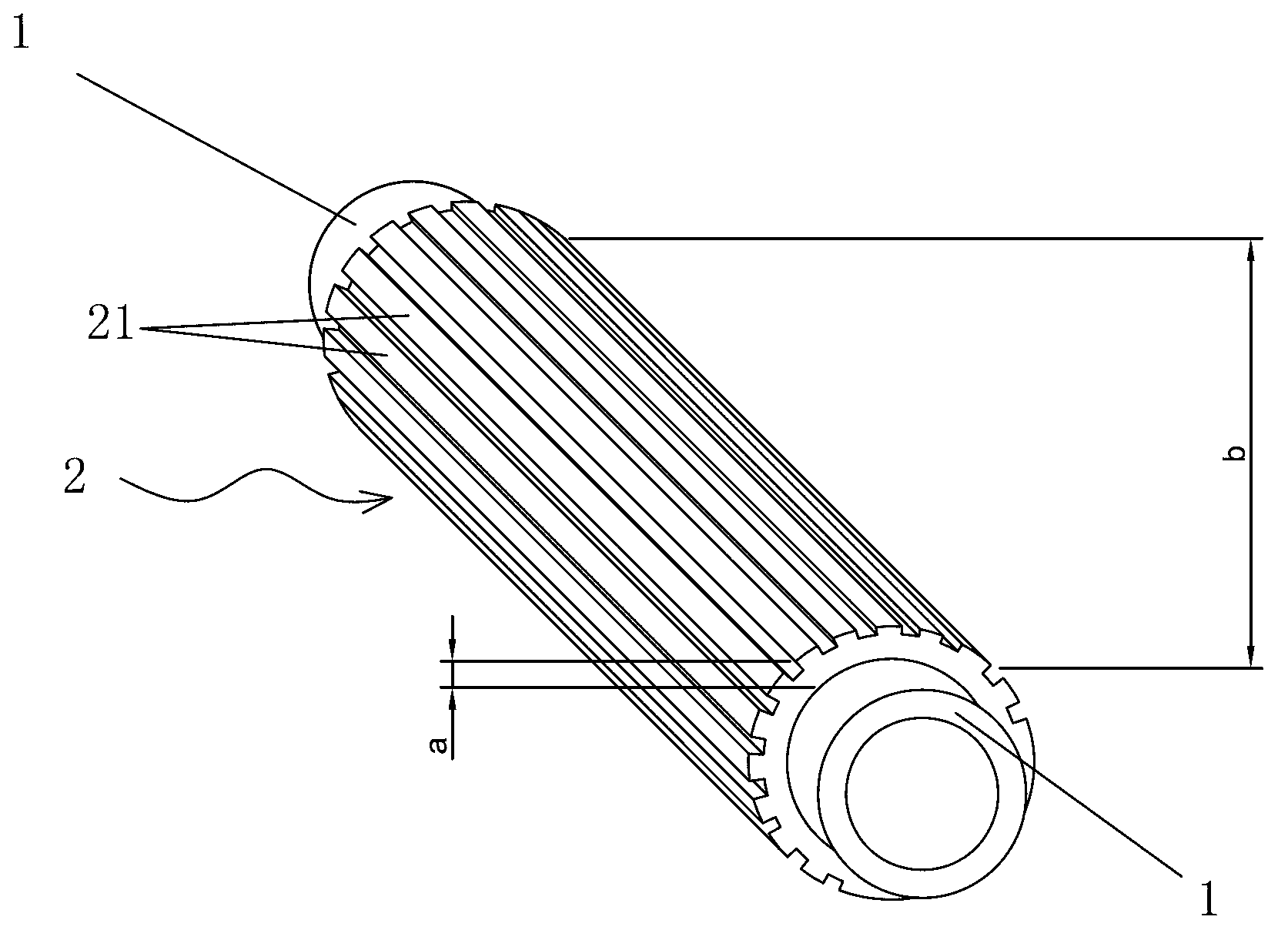

[0029] like figure 2 As shown, the outer peripheral surface of the drum 1 is tightly wrapped with an elastic and wear-resistant outer layer, also known as the threshing roller 2. The threshing roller 2 can be made of rubber or silica gel coating. The thickness of the coating is a is between 5-20 mm, preferably 10 mm, and the axial length b of the threshing roller 2 is between 1000-1500 mm, preferably 1200 mm.

[0030] The threshing roller 2 can be a smooth surface, or a non-smooth surface with several racks...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Layer thickness | aaaaa | aaaaa |

| Axial length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com