A method of manufacturing a laminated fabric core conveyor belt

A fabric core and conveyor belt technology, applied in conveyors, chemical instruments and methods, lamination, etc., can solve the problems of low adhesion, delamination, and uneven tension of the fabric core layer, and achieve uniform interlayer tension and efficiency. High, poor safety effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

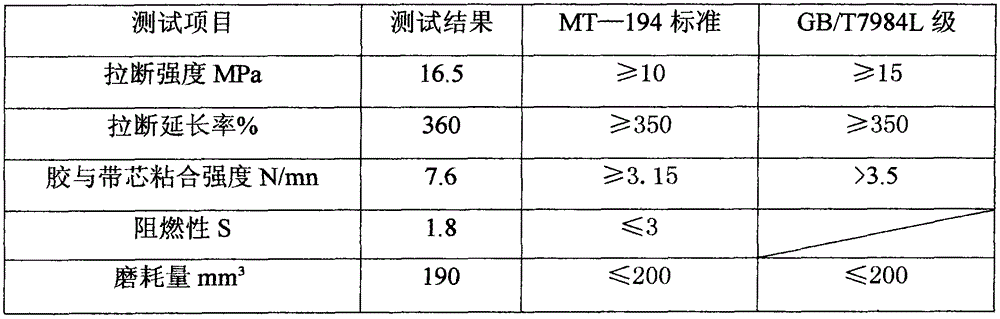

Examples

Embodiment 1

[0024] The preparation of embodiment 1 laminated fabric core conveyor belt

[0025] (1) Two or more layers of chemical fiber fabric core layers are thermally bonded into a whole belt core by ultrasonic bonding equipment; ultrasonic bonding equipment converts electrical energy into mechanical vibration energy, so that the surface between chemical fiber layers is melted and bonded Function, improve the adhesion and integrity between layers. Wherein, the fabric core layer used is woven alone or mixed with different kinds of chemical fibers.

[0026] (2) The integral tape core is dipped and plasticized to become a skeleton material; the bonded integral tape core is dipped and plasticized to become a dipped tape core; the dipped paste used is composed of the following components by weight: Made of: 100 kg of PVC paste resin, 50 kg of dioctyl fat, 3-4 kg of stabilizer, 6-8 kg of antistatic agent, 45-47 kg of 45% oxidized paraffin, 4.5-5.5 kg of 3.5-water zinc borate, three aromatic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com