Sensor of hydraulic gear selecting and shifting manipulation mechanism of automatic mechanical gearbox

A technology of automatic machinery and operating mechanism, applied in mechanical equipment, transmission control, components with teeth, etc., can solve the problems of low driving comfort, cumbersome control, few technologies, etc., to improve maneuverability and safety, The effect of flexible handle and improved cost performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] Below in conjunction with accompanying drawing and specific embodiment the present invention will be further described:

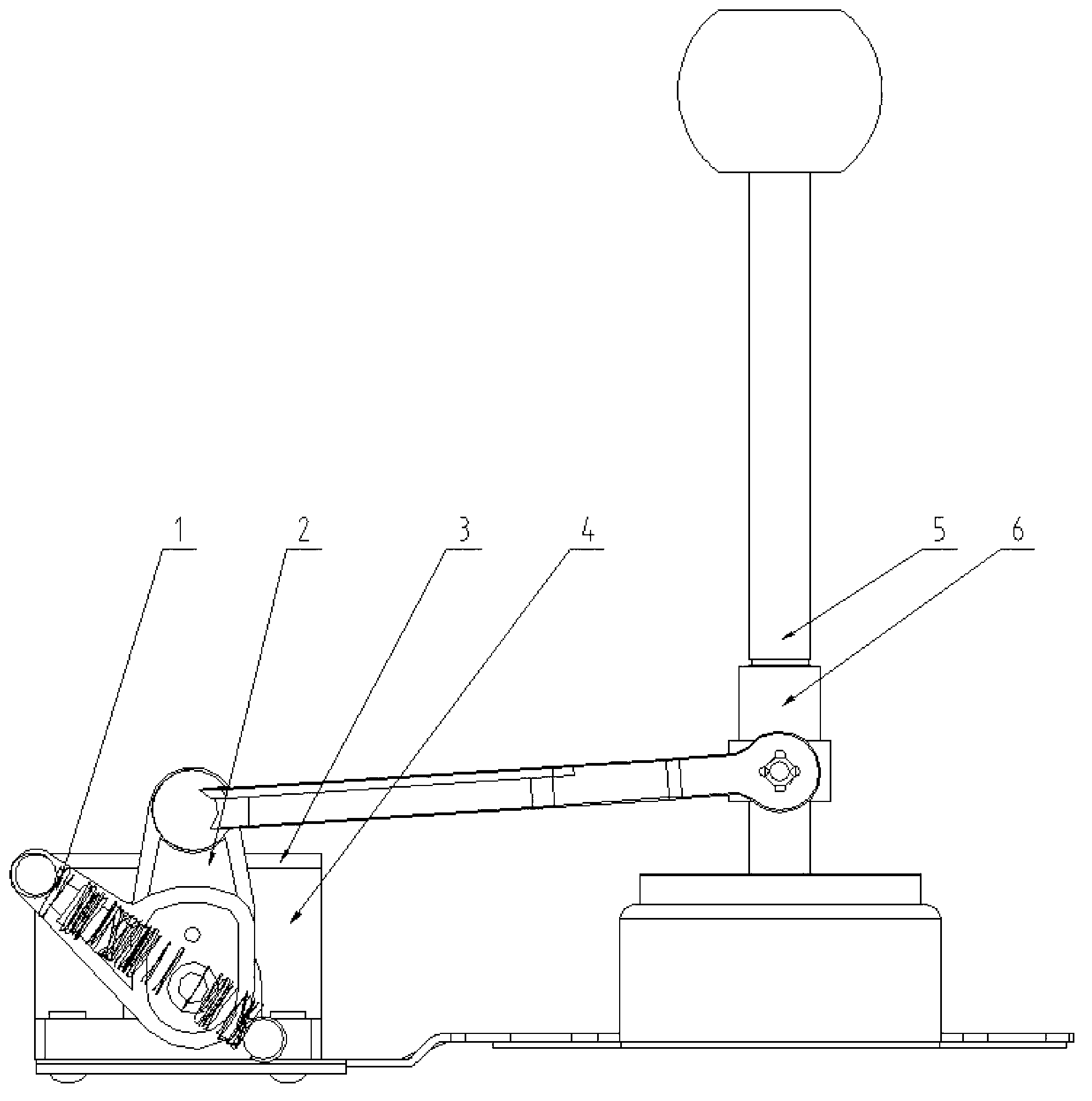

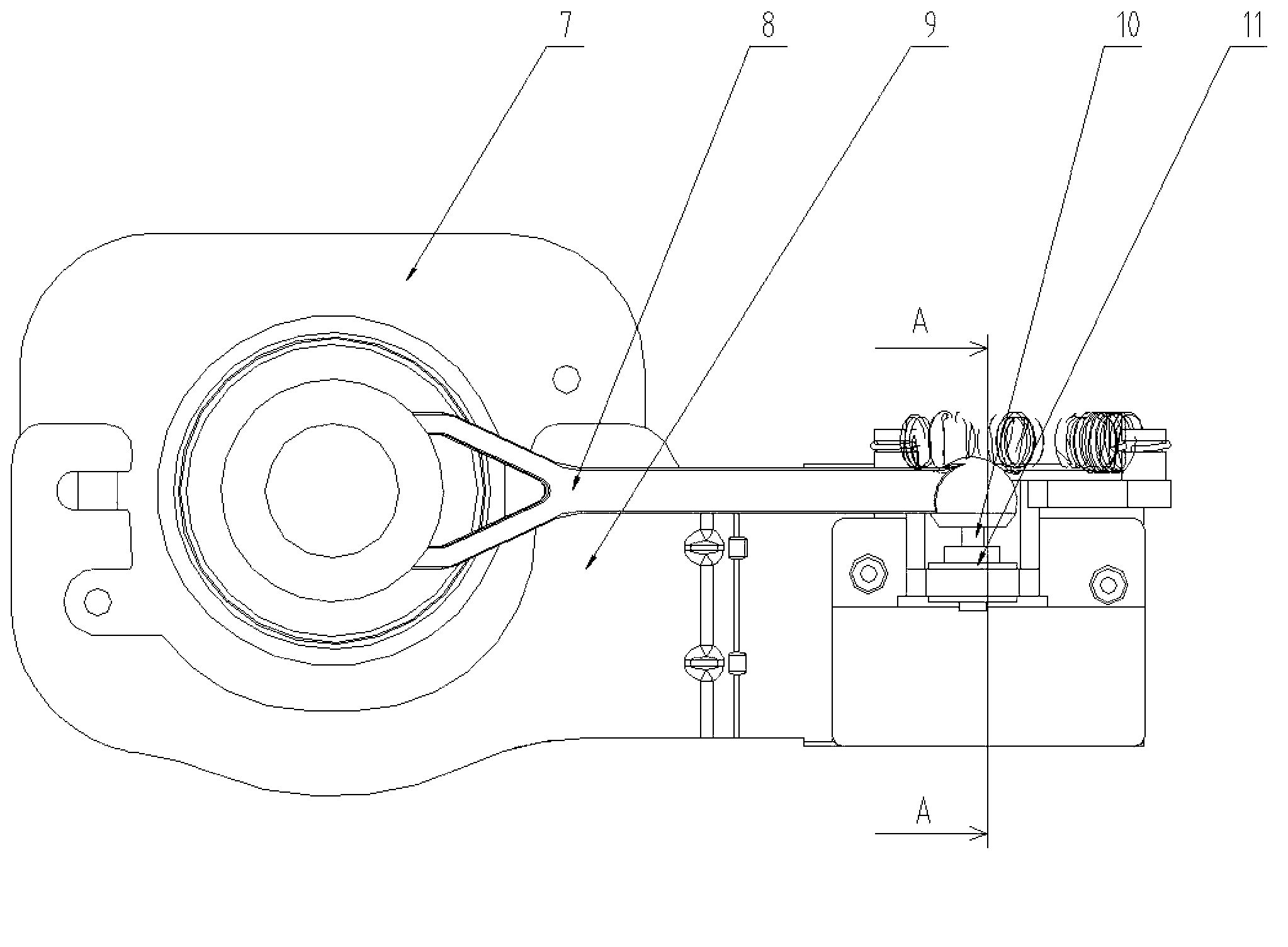

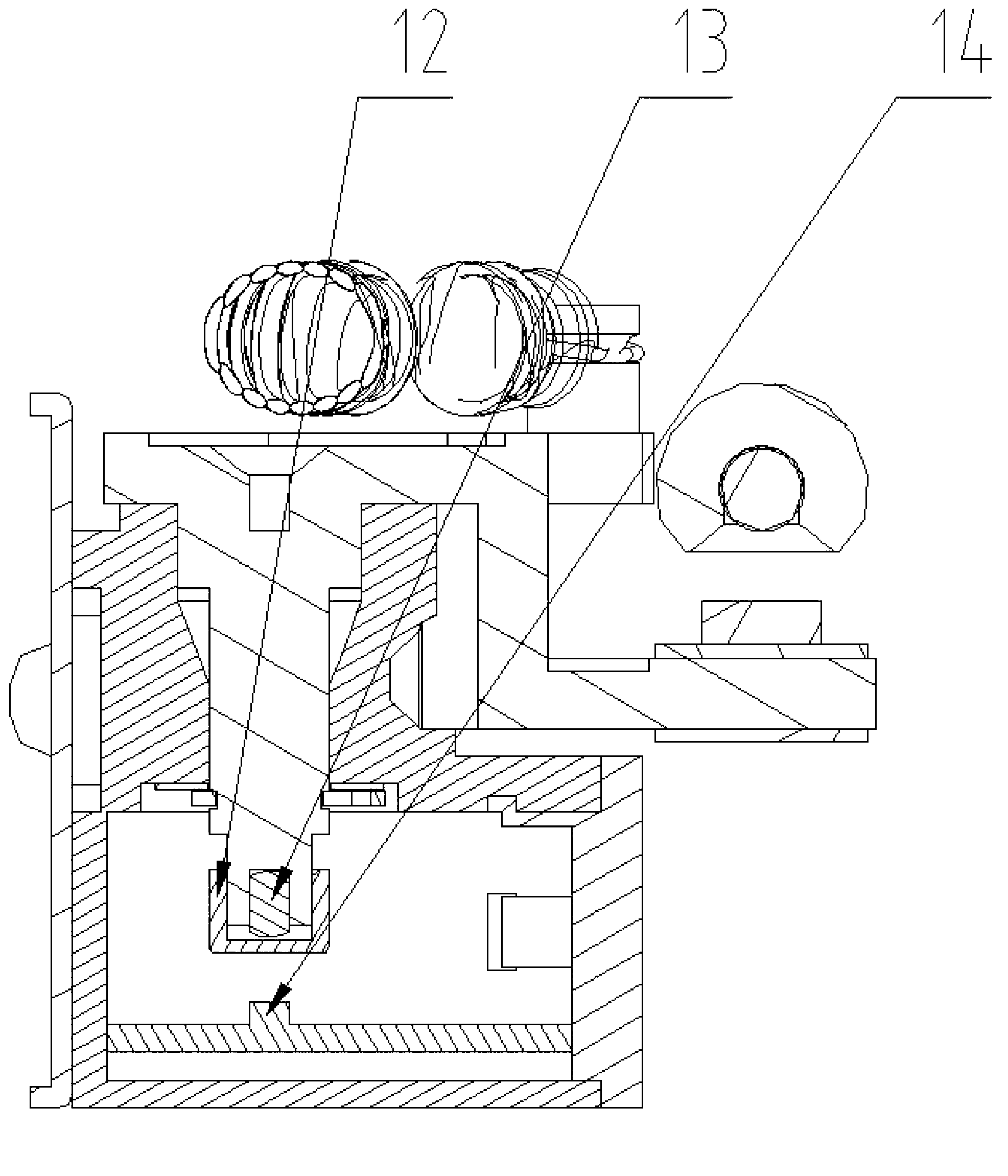

[0011] combine Figure 1-Figure 3 , the present embodiment includes shift force return spring 1, shift force pendulum 2, shift force sensor upper cover 3, shift force sensor mechanism body 4, original car gear lever 5, gear lever fastening sleeve 6, original vehicle gear Rod base 7, shift force connecting rod 8, shift force bracket 9, shift force ball head 10, shift force ball head gasket 11, magnetic column lock nut 12, magnet 13, sensor 14, shift force mechanism The body 4 is connected to the shift force bracket 9 through rivets, the shift force pendulum 2 is fixed on the shift force mechanism body 4 through a circlip, and the reset of the shift force pendulum 2 is connected to the shift force mechanism body 1 through the shift force reset spring 1. On the power mechanism body 4, realize the reset function in the work, the original car gear lever ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com