Low-alloy steel having a high yield strength and a high sulphide-induced stress cracking resistance

A stress cracking, low-alloy steel technology, applied in the field of low-alloy steel, to solve problems such as yield strength drop

Inactive Publication Date: 2013-02-20

VALLOUREC OIL & GAS FRANCE SAS

View PDF5 Cites 3 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, since there is thereby a risk that the yield strength of the steel will drop due to the high tempering temperature, patent application EP1862561 proposes to increase

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

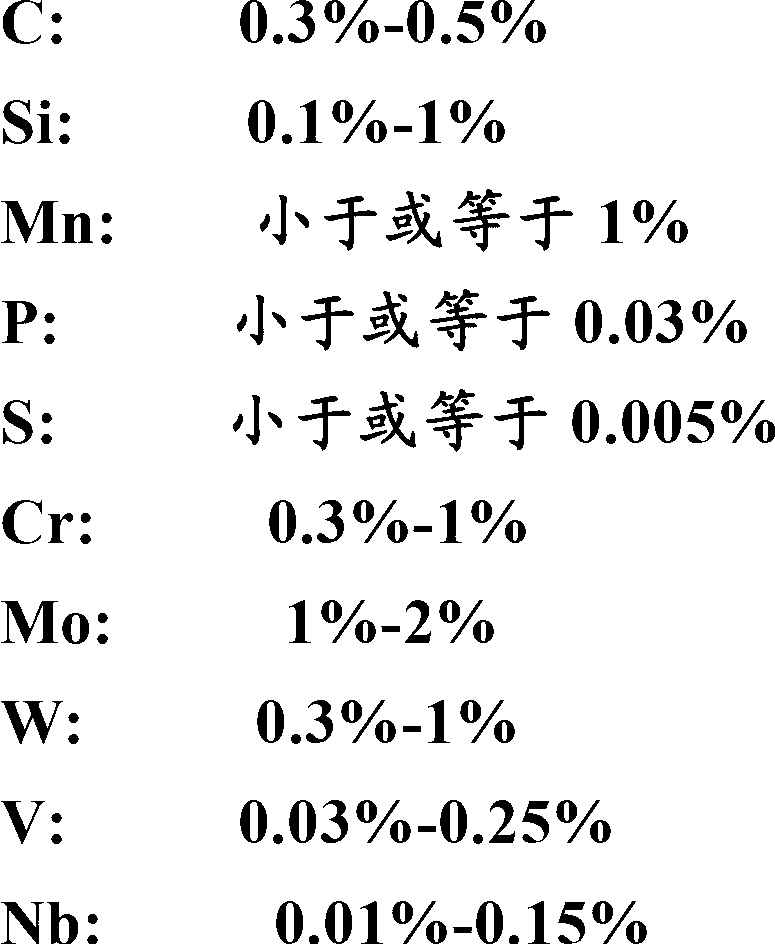

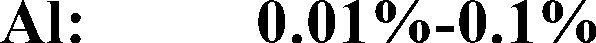

Steel containing, by weight: 0.3 to 0.5% C; 0.1 to 1% Si; 1% Mn or less; 0.03% P or less; 0.005% S or less; 0.3 to 1% Cr; 1 to 2% Mo; 0.3 to 1% W; 0.03 to 0.25% V; 0.01 to 0.15% Nb; 0.01 to 0.1% Al, the balance of the chemical composition of the steel consisting of Fe and impurities or residuals resulting from or as a necessary consequence of the smelting and casting processes carried out on the steel. The steel serves for manufacturing weldless pipes for hydrocarbon wells, the yield strength of the steel after heat treatment being equal to or greater than 862 MPa, or even equal to or greater than 965 MPa.

Description

Technical field [0001] The present invention relates to a low-alloy steel with high yield strength (limite d'élasticité), which has excellent resistance to sulfide stress cracking. The present invention is particularly suitable for containing hydrogen sulfide (H 2 S) Tubular products for hydrocarbon wells. Background technique [0002] With higher and higher pressure, higher and higher temperatures and in increasingly corrosive media (especially when it is loaded with hydrogen sulfide), deeper and deeper exploration of hydrocarbon wells And development, the demand for the use of low-alloy steel pipes that have both high yield strength and high resistance to stress cracking caused by sulfides is increasing. [0003] This is because hydrogen sulfide H 2 The presence of S is the cause of the dangerous cracking form of low alloy steel with high yield strength. The cracking is known as Sulfide Stress Cracking or SSC (Sulfide Stress Cracking), which may affect both casing and casing. A...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C22C38/02C22C38/04C22C38/12C22C38/22C22C38/24C22C38/26

CPCC22C38/02C22C38/26C22C38/12C22C38/04C22C38/22C22C38/24

Inventor L·德拉特H·马尔什布瓦M·皮耶特C·博什M·赫斯特梅尔J·康拉德

Owner VALLOUREC OIL & GAS FRANCE SAS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com