Sowing streamline apparatus

A technology of assembly line and seeding mechanism, which is applied in the direction of interval-type quantitative seeding machinery and other directions, can solve problems such as affecting seed growth, production offset of sowing position, and complex mechanism structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

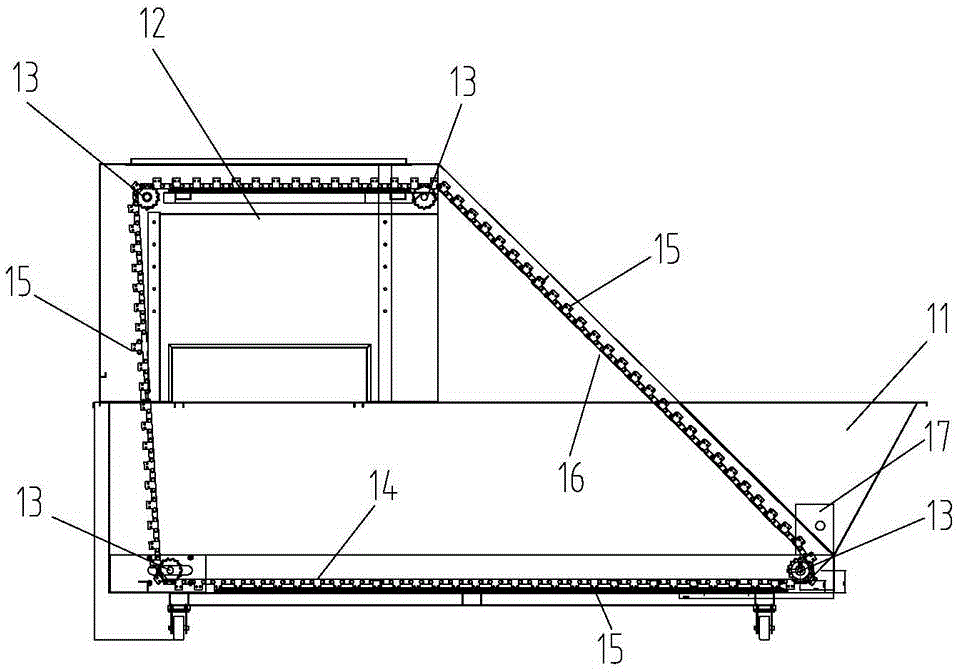

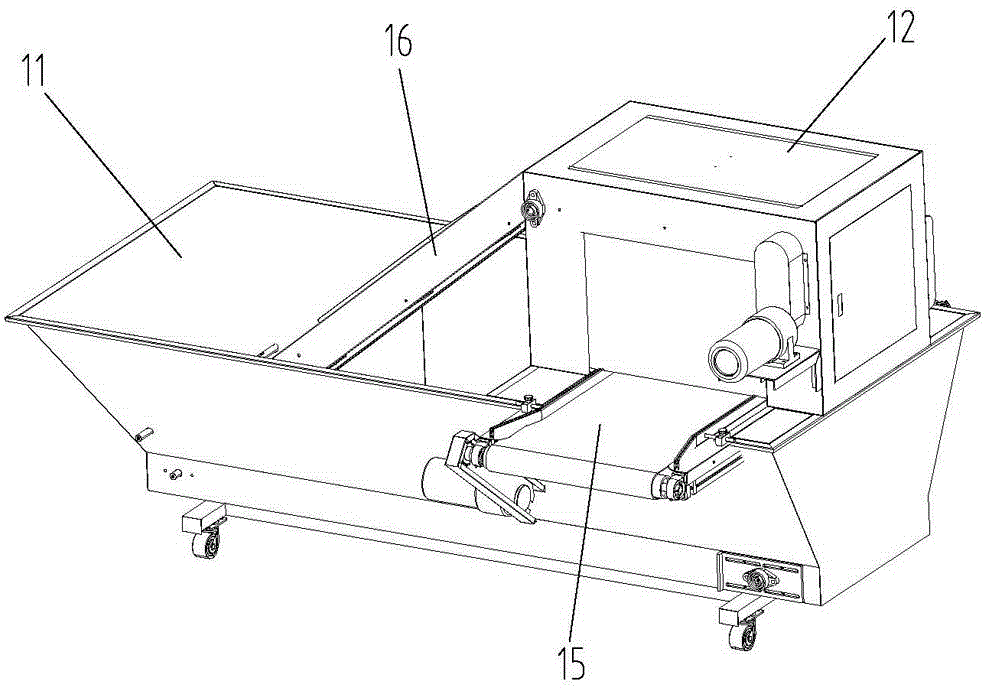

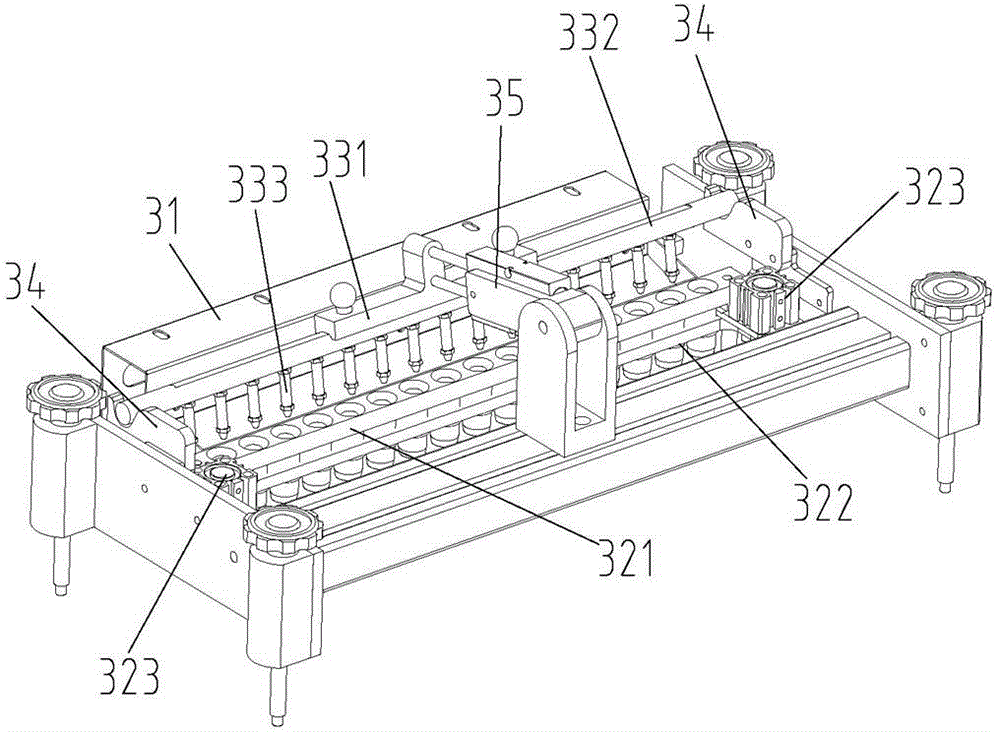

[0020] Such as figure 1 As shown in -7, a planting assembly line device mainly includes a soil loading mechanism 1, a seeding mechanism 3, a soil covering mechanism 2 and a sprinkler mechanism 4, and the conveyor belt devices 5 of each mechanism are connected end to end to form a transmission channel. The soil loading mechanism 1 includes a hopper 11, a conveyor belt device 5 and an upper soil hopper 12, the described upper soil hopper 12 is arranged above the conveyor belt 5 12, the described conveyor belt device 5 and the upper soil hopper 12 are arranged in the hopper 11, inside the hopper 11 The front and rear parts of the left and right ends are all provided with sprocket wheels 13, and the front and rear parts of the top left and right ends of the top of the upper soil hopper are also provided with sprocket wheels 13. A chain 14 matched with it is provided to form two sets of transmission chains, a number of partitions 15 are arranged in parallel between the two sets of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com