Vacuum discharge reaction kettle

A reactor and vacuum technology, applied in the field of vacuum discharge reactor, can solve problems such as vacuum pump blockage, achieve high production efficiency, good economic benefits, and prolong the practical life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

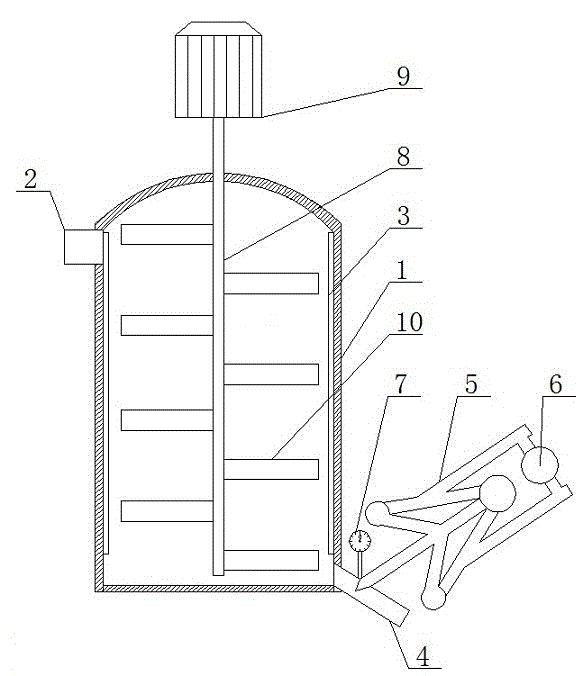

[0013] as attached figure 1 Shown: the vacuum discharge reaction kettle of the present invention comprises a kettle body 1, the described kettle body is provided with a feeding port 2, a stirring device is installed inside the described kettle body, and an electric heating rod 3 is arranged inside the described kettle body , the discharge pipe 4 is connected below the kettle body, the discharge pipe is connected to the labyrinth vacuum pipeline 5, the labyrinth vacuum pipeline is connected to the vacuum pump 6, and the labyrinth vacuum pipeline is connected to the described vacuum pipeline. Vacuum meter 7 is installed at the junction of the discharge pipe, the angle between the installation angle of the discharge pipe and the horizontal plane is -15 ° ~ -90 °, the installation angle of the labyrinth vacuum pipeline and the horizontal plane The angle between them is 15°~90°.

Embodiment 2

[0015] In the vacuum discharge reactor described in Example 1, the stirring device includes a stirring shaft 8, the stirring shaft is connected to a driving motor 9, and a stirring blade 10 is installed on the stirring shaft.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com