Welding process parameter recording and welding quality analysis system

A technology of parameter recording and welding process, applied in welding equipment, arc welding equipment, manufacturing tools, etc., can solve the problems of difficult on-site wiring, untraceable welding quality, unanalyzable welding quality, etc., to improve welding quality and high acquisition frequency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

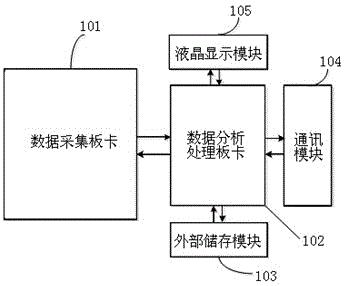

[0016] Such as figure 1 The structural diagram of the welding process parameter recording and welding quality analysis system is shown in the figure. The entire welding process parameter recording and welding quality analysis system consists of a data acquisition board 101, a data analysis and processing board 102, an external storage module 103, a communication module 104, and a liquid crystal display module. 105 composition. The data acquisition board 101 collects welding-related data and transmits it to the data analysis and processing board 102 for data processing and analysis. The analyzed data can be displayed through the liquid crystal display module 105 and stored in the external storage module 103, or transmitted through the communication module 104 Perform post-processing for the host computer PC.

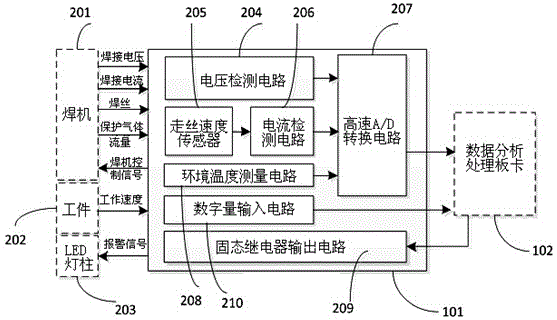

[0017] Such as figure 2 The structure diagram of the data acquisition board is shown, the data acquisition board 101 is composed of a voltage detection circuit 204, a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com