Rack piston internal spiral rollaway nest clamp

A technology in the spiral raceway and piston, which is applied in the direction of grinding the workpiece support, etc., can solve the problems of low processing quality and efficiency, poor workpiece accuracy, and affecting driving safety, so as to improve processing efficiency and processing quality. Effect of long life and high centering accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

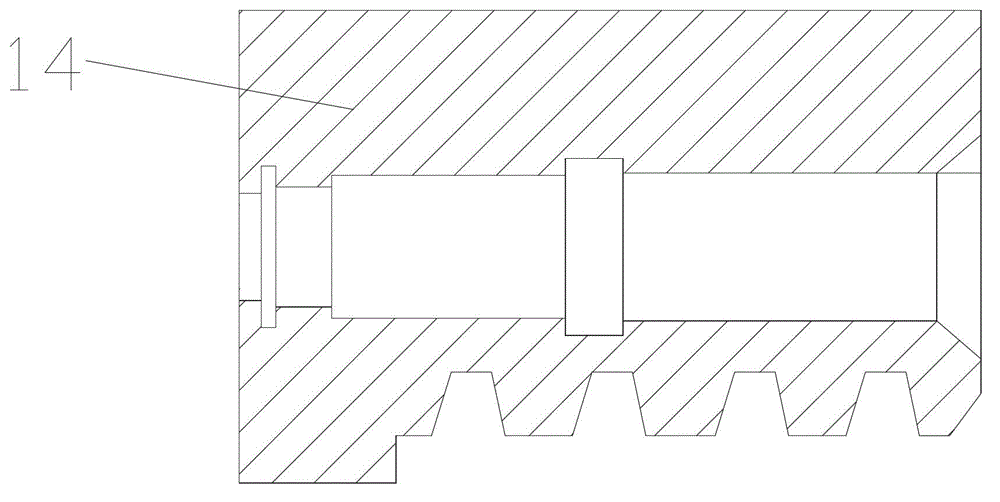

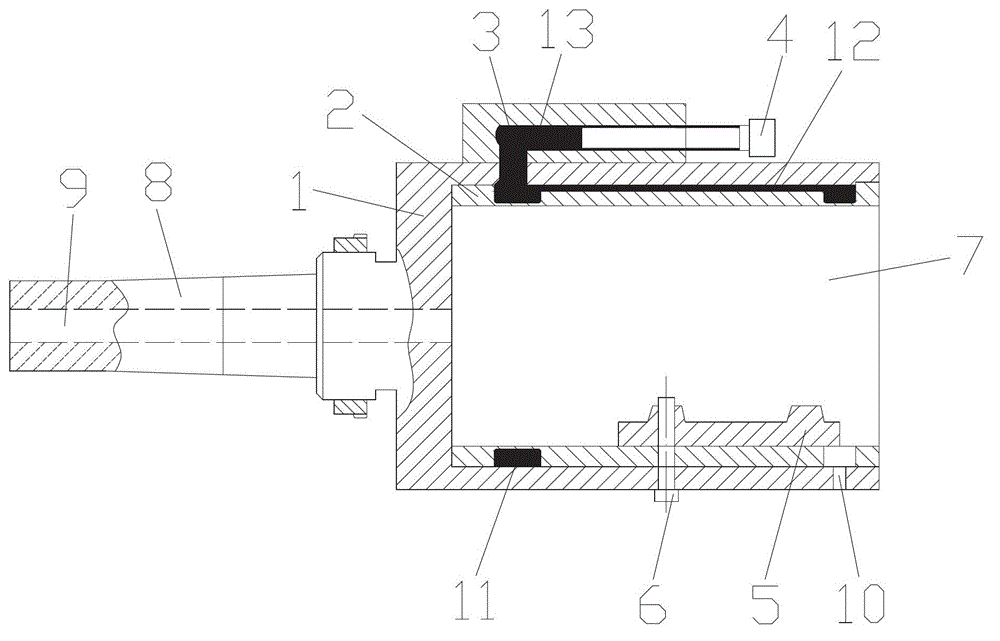

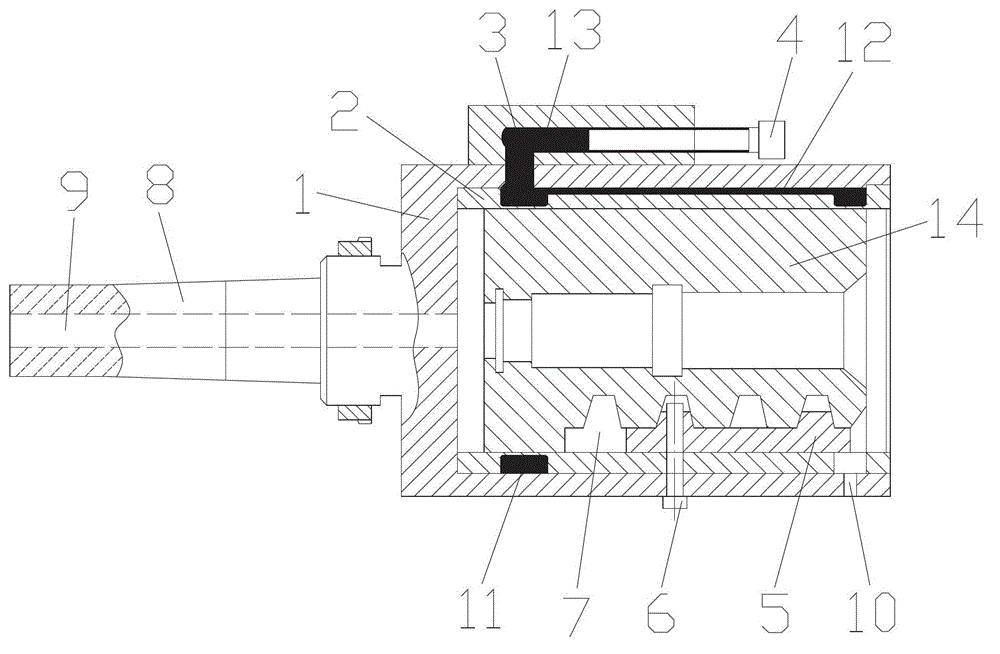

[0016] The present invention is described below in conjunction with accompanying drawing.

[0017] as attached figure 2 The shown rack piston inner spiral raceway fixture of the present invention includes a fixture body 1, a thin-walled sleeve 2, liquid plastic 3, an adjusting bolt 4, a toothed positioning block 5 and a fixing pin 6; The end surface of the clamp body 1 has an inner hole 7; the end of the clamp body 1 without the inner hole 7 is provided with a connecting column 8; the connecting column 8 is in the shape of a cone with a small outer end and a larger inner end; There is a through hole 9 in the connecting column 8; the through hole 9 communicates with the inner hole 7; the inner hole 7 is provided with a matching thin-walled sleeve 2; the thin-walled sleeve 2 passes through the set bolt 10 It is fixed in the inner hole 7 of the fixture body 1; the set bolt 10 is close to the outer port of the thin-walled sleeve 2; the surface of the thin-walled sleeve 2 is prov...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap