Ultrasonic welding jig of T25 cell culture bottle

A technology for ultrasonic welding and cell culture, which is applied in the field of ultrasonic welding fixtures for T25 cell culture bottles, and can solve problems such as scratches, wear of the bottle body 1, and decreased aesthetics of T25 cell culture bottles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

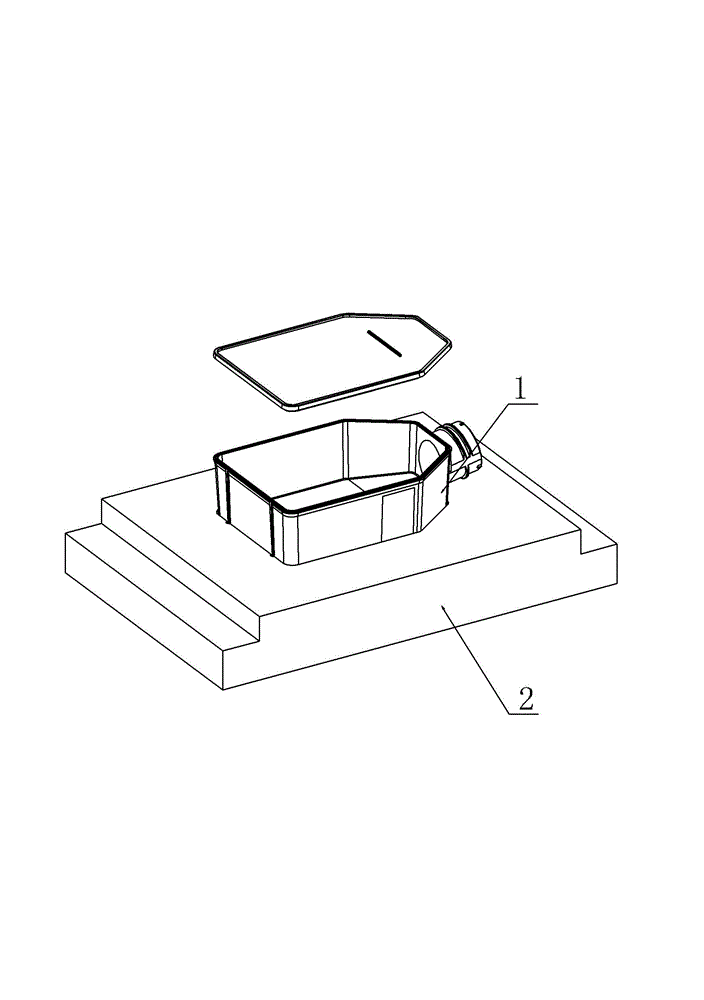

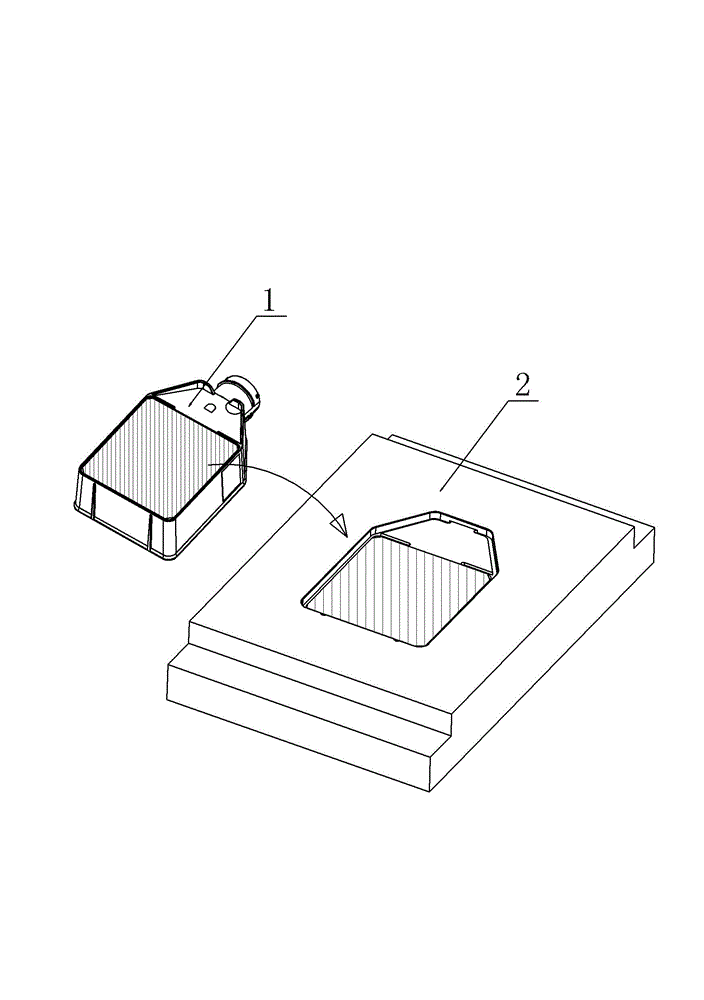

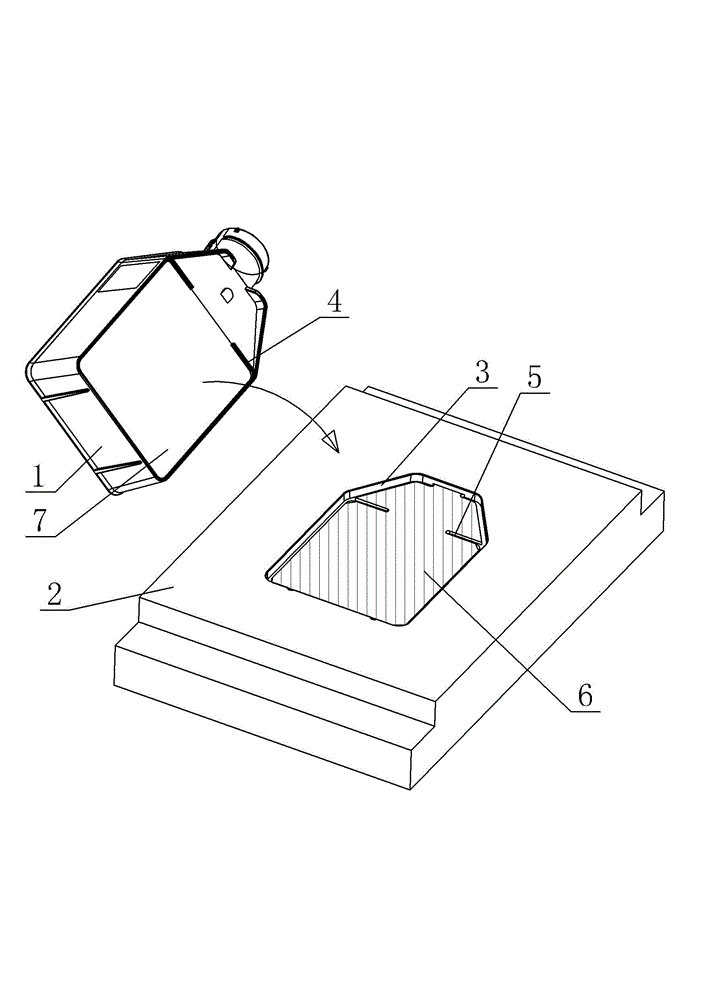

[0009] See image 3 , which includes a bottle body 1, a jig base 2, one side of the jig base 2 has a groove 3 consistent with the shape of the lower surface 7 of the bottle body 1, and the groove 3 corresponds to the rib position 4 of the bottle body 1 The position has rib position groove 5, and the horizontal height of the remaining bottom surface part 6 of groove 3 is lower than the horizontal height of rib position groove 5, and the rib position 4 of bottle body 1 is supported in rib position groove 5, the lower surface of bottle body 1 7 is not in contact with the bottom surface portion 6 of the groove 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com