Laser transmission welding follow-up clamping device

A technology of laser transmission welding and clamping device, which is applied in the field of laser welding, can solve the problems of easy-wearing glass ball optical properties, inability to realize three-dimensional weld seam welding, and unstable welding quality, and achieve compact structure, stable weld seam quality, Versatile effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

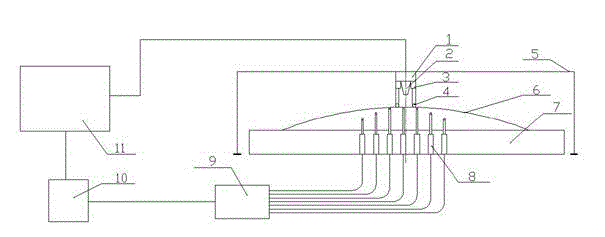

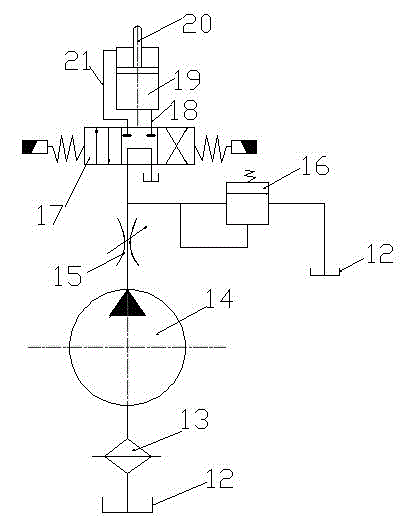

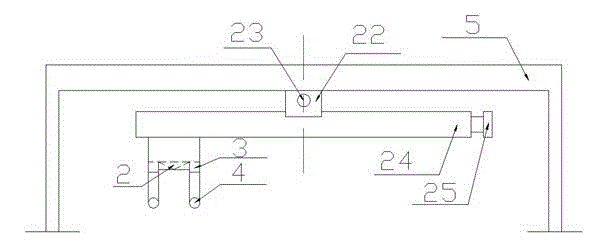

[0020] Such as figure 1 As shown, the laser transmission welding follower fixture includes a PC 11 , a PLC controller 10 , a hydraulic control system 9 , a support assembly, a pressure head assembly, a pressure head fixing assembly and a bracket 5 . The support assembly includes a small hydraulic thimble assembly 8 and a support plate 7; the indenter assembly includes a laser head base 1, a laser head 2, a pressure sensor 3 and a pressure roller 4; the indenter fixing assembly has two There are two schemes, the first scheme is called fixed style, and the second scheme is called free style. The specific implementation scheme is described with the first scheme.

[0021] A square array of holes is opened on the support plate 7, and a small hydraulic thimble assembly 8 is placed in the holes. Each hydraulic small thimble assembly has a specific number and can be individually controlled through a program. When the ejector bar is in the retracted position, the top end of the ejec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com