Simplified wheel type transportation vehicle suitable for mountain orchards

A transporter and orchard technology, which is applied in the direction of transportation and packaging, the upper structure of the truck, the upper structure, etc., can solve the problems of high cost and low flexibility, and achieve the effects of small mechanical wear, simplified layout, and flexible steering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

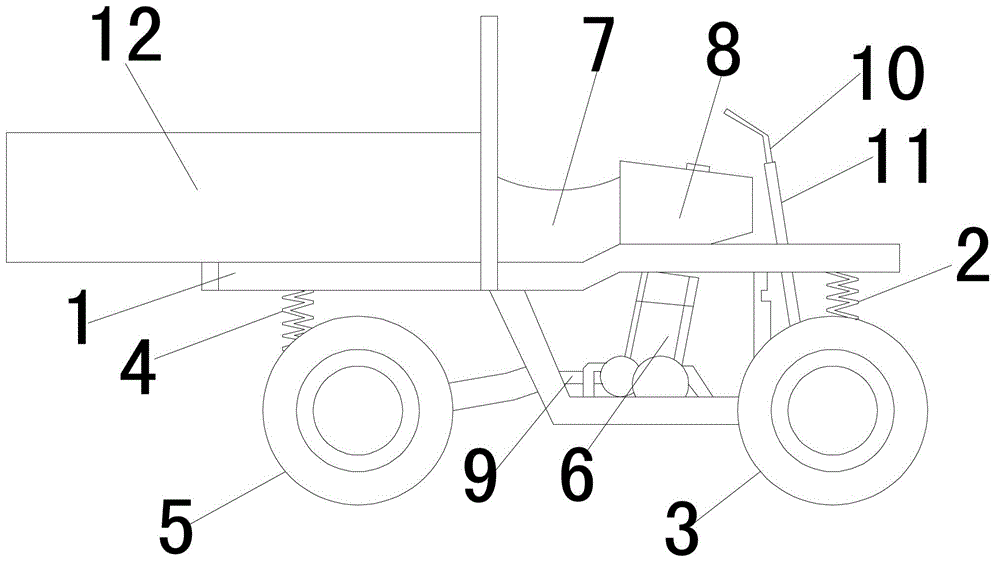

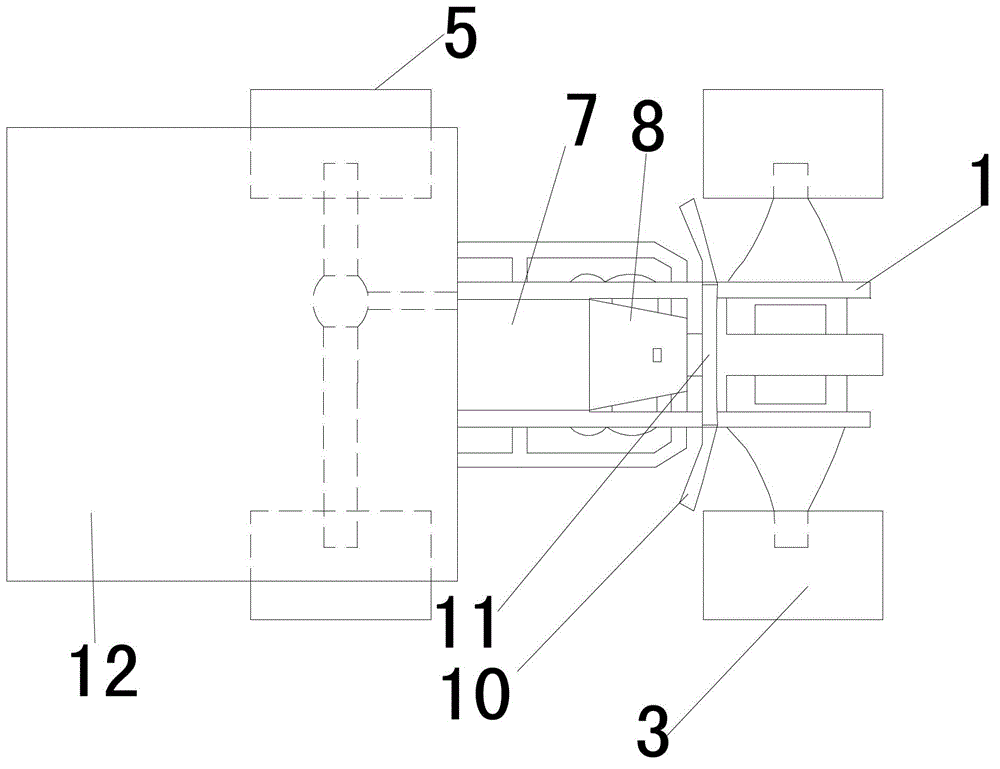

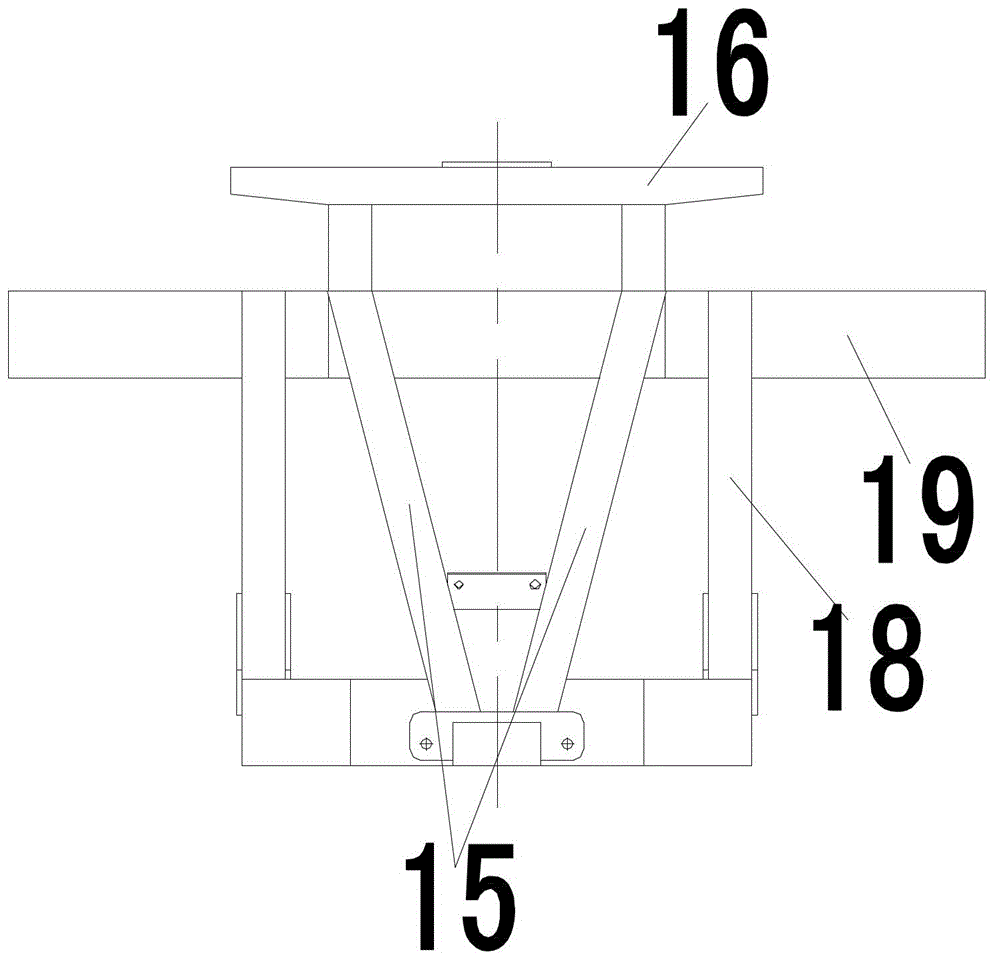

[0032] Such as Figure 1~6 As shown, a light and simplified wheeled transporter suitable for mountain orchards includes a car body, the front end of the car body is connected to the front axle through a front suspension assembly 2, front wheels 3 are arranged at both ends of the front axle, and the rear end of the car body passes through The rear suspension assembly 4 is connected with the rear axle, and the rear drive wheels 5 are arranged at the two ends of the rear axle. On the mounting part on the lower side of the front part of the car body, the engine 6 on the mounting part is connected to the rear driving wheel 5 through a transmission mechanism. The upper side of the front part of the car body is provided with a driver's seat 7 and a fuel tank 8, and the front position of the driver's seat 7 is provided with a steering wheel. mechanism, the steering mechanism controls the steering of the front wheel 3, and the front wheel 3 and the rear drive wheel 5 are respectively p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com