Detection device for steel wire rope tension of friction type hoister

A tension detection and steel wire rope technology, which is applied in the field of friction hoist wire rope tension detection devices, can solve the problems of not forming high reliability, mature products, and difficulty in making effective, so as to achieve effective and reliable detection devices, reliable control performance, and detection high precision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

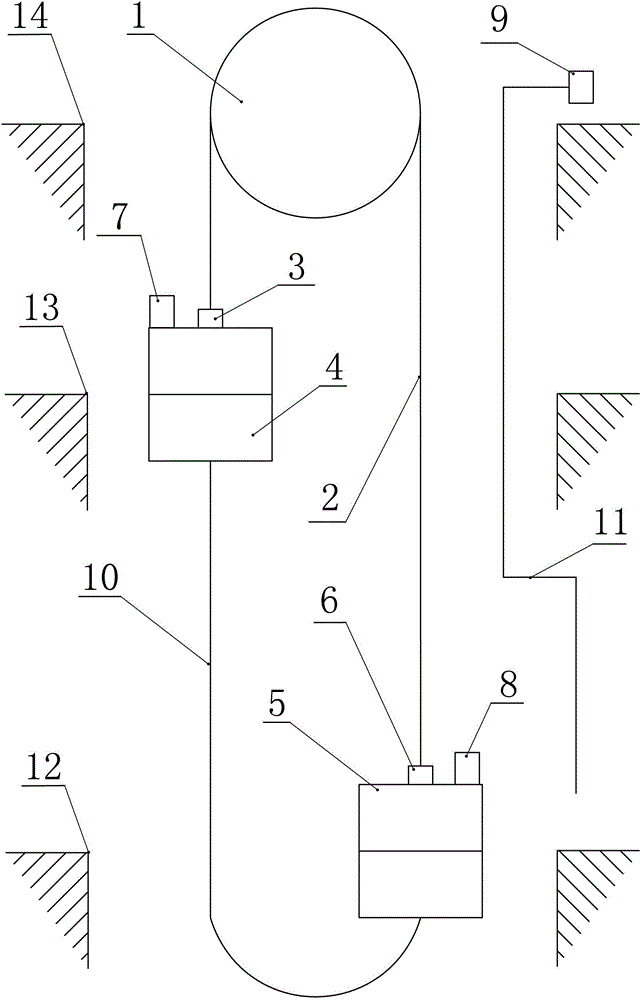

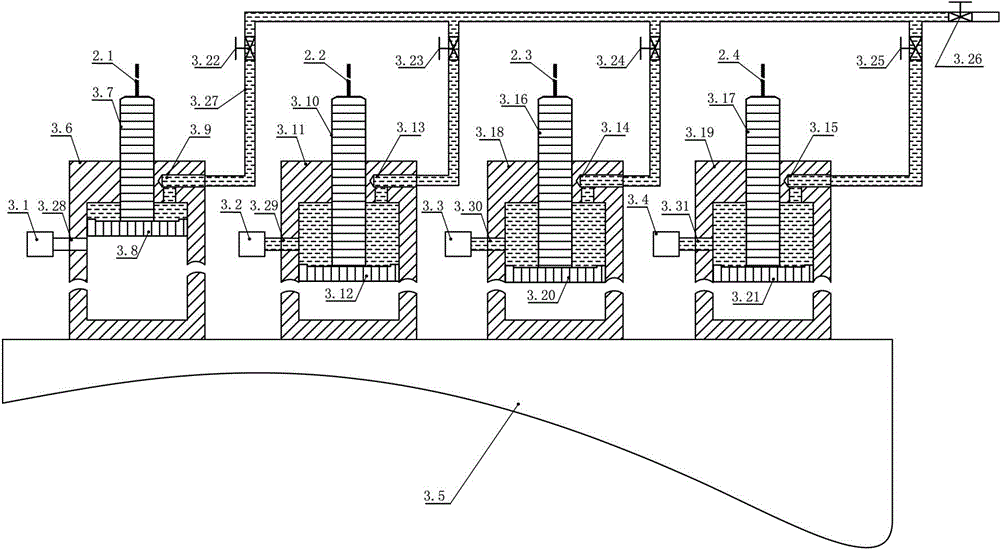

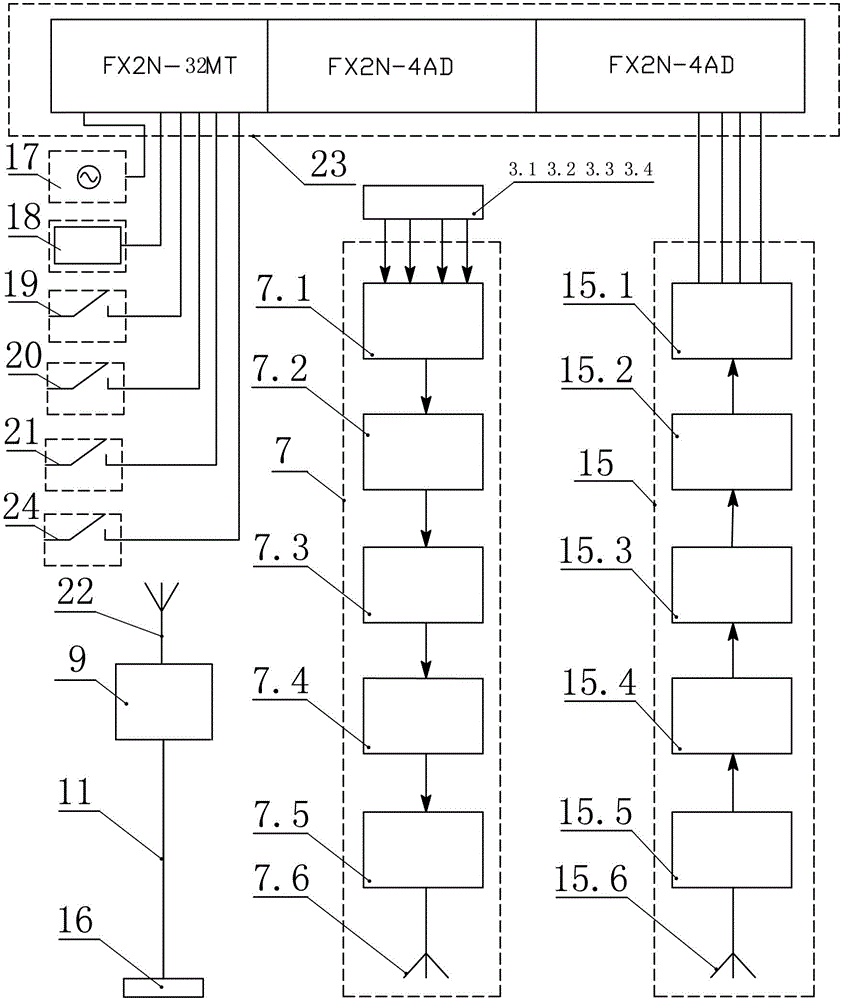

[0032] The present invention as figure 1 , 2 , 3, a friction hoist steel wire rope tension detection device, including a friction drum 1, a steel wire rope 2, two cages 4,5, the steel wire rope 2 rides on the friction drum 1, and the two ends of the steel wire rope 2 are connected to two cages 4 , 5, the two ends of the balance rope 10 are connected to the lower ends of the two cages 4, 5, which are characterized in that: two full hydraulic automatic balancing devices 3, 6 are installed on the two cages 4, 5 respectively, and the two full hydraulic automatic balancing devices Devices 3 and 6 are respectively connected to both ends of the wire rope 2, two wire rope tension sending parts 7 and 8 are respectively installed on two cages 4 and 5, the wire rope tension receiving part is installed in the hoisting machine room 14, and the base station 9 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com