A biomass dry distillation and power generation system

A power generation system and biomass technology, which is applied in the field of biomass dry distillation and power generation system, can solve the problems of poor compost quality, occupy large land, and oppose the establishment of incineration plants, so as to improve the reaction speed, reduce the damage to the environment and the atmosphere, Realize the effect of recycling and recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

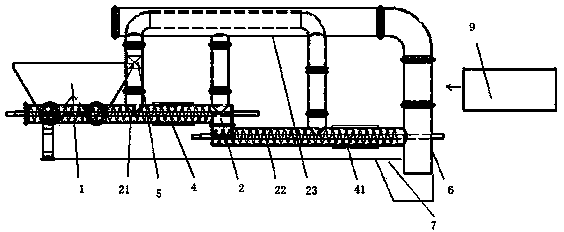

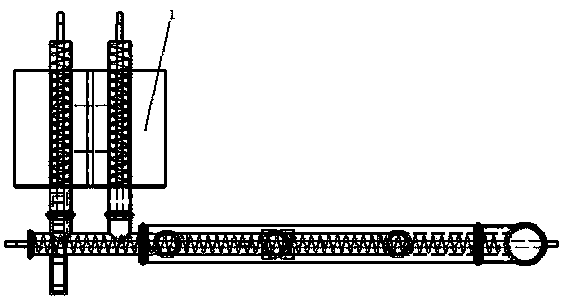

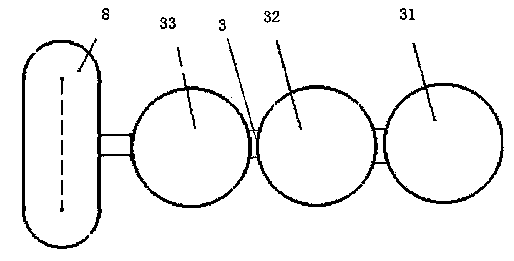

[0021] refer to figure 1 , the present invention is a biomass carbonization and power generation system, characterized in that it includes a carbonization reactor feed device (1) carbonization reactor (2) carbonization reactor gas cooling and purification system (3) heating system (4, 41 ) Adjusting device of retort reactor (5) carbon cabinet (6) carbon discharge pool (7) gas generator set (8) wireless remote control system (9). The dry distillation reactor feeding device (1) is connected to the feed port of the dry distillation reactor (2), and the dry distillation reactor gas cooling and purification system (3) is connected to the dry distillation reactor (2) at one end, and the other end is connected to the gas power generation The unit (8) is connected with each other, the carbon cabinet (6) is connected with the discharge port of the carbonization reactor (2), and the output port of the carbon cabinet (6) is inserted into the water of the carbon discharge pool (7).

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com