A high-temperature and high-pressure carbonization device in an oxygen-free state

A technology of chemical device and discharge device, used in special forms of dry distillation, petroleum industry, pyrolysis treatment of sludge, etc., can solve the problem of occupying a large amount of land, reduce environmental and atmospheric damage, improve reaction speed, and realize circulation. and the effect of recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

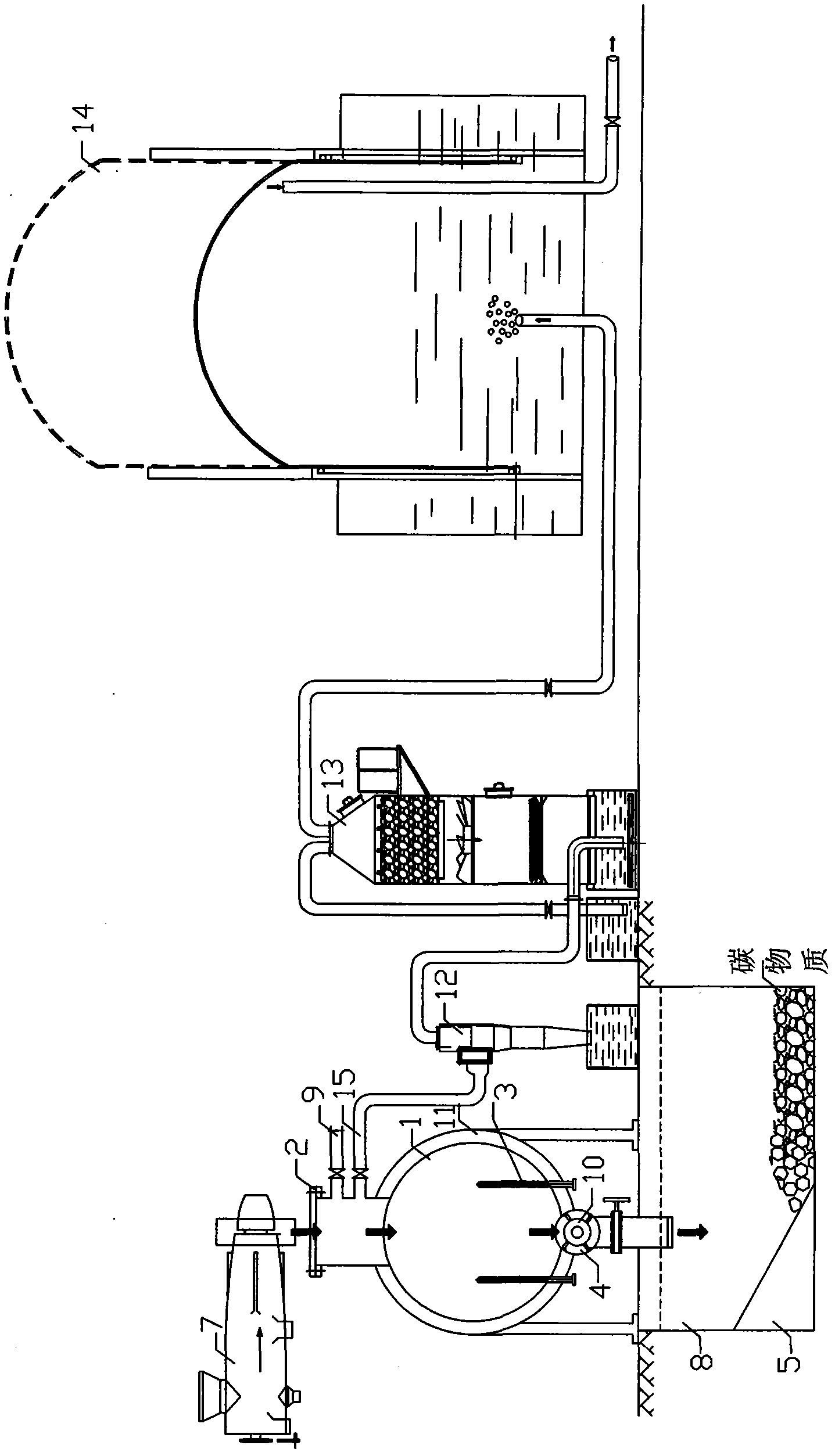

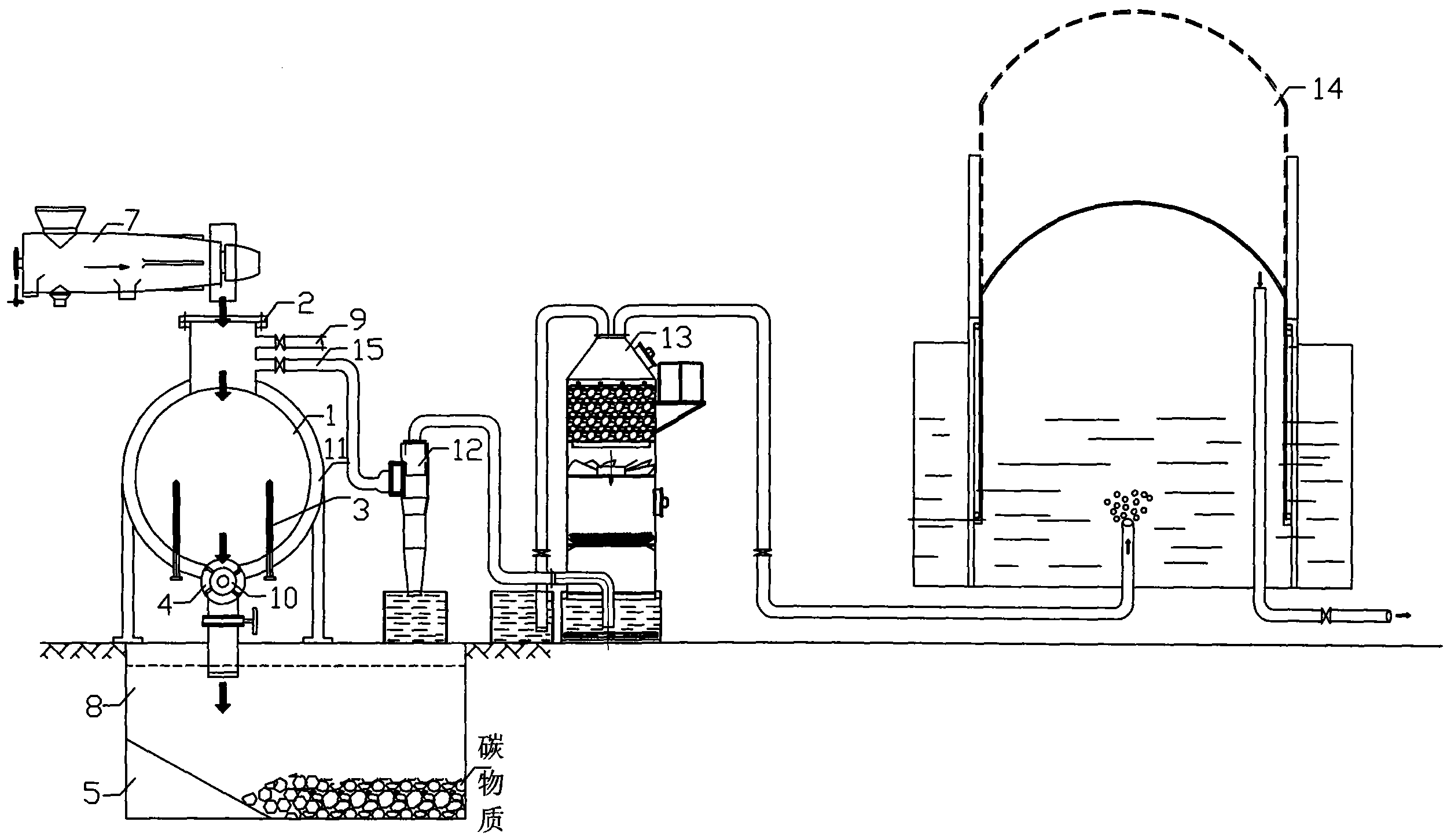

[0020] refer to figure 1 , a kind of refuse carbonization device of the present invention, comprises carbonization reactor 1, feed device 2, heating device 3, gas output device 15 and discharge device 4, the output port of feed device 2 and the inner chamber of carbonization reactor 1 connection, the input port of the discharge device 4 is connected with the inner cavity of the carbonization reactor 1, the output port of the discharge device 4 is connected with an external carbon collection device 5, and the input port of the gas output device 15 is connected with the carbonization sensor 1, and the output end of the gas output device 15 is connected with an external gas processing device 6. The heating device 3 is generally an electric heating rod, and the electric heating rod is arranged near the lower part of the inner chamber of the carbonization reactor 1 . In order to carry out the carbonization process safely, the garbage carbonization device is also preferably provide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com