Device for destructive distillation and drying of biomass

A drying device and biomass technology, applied in the direction of retort gas discharge device, biofuel, special form of retort, etc., can solve the problems of large land occupation, high cost of deodorization, poor compost quality, etc., to reduce environmental and The effect of destroying the atmosphere, realizing recycling and recycling, and increasing the reaction speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

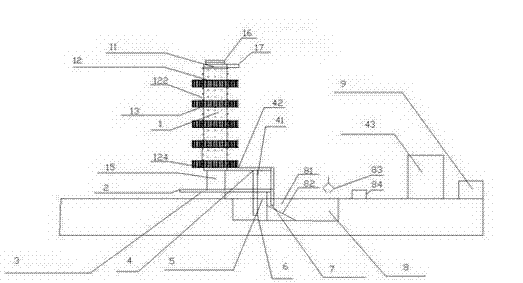

[0015] refer to figure 1 , The present invention provides a biomass dry distillation device that does not produce pollution during the operation process and has a high degree of resource reuse.

[0016] The technical scheme that the present invention adopts for solving its technical problem is:

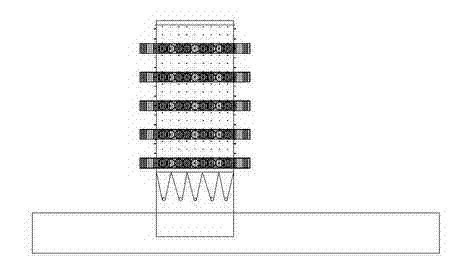

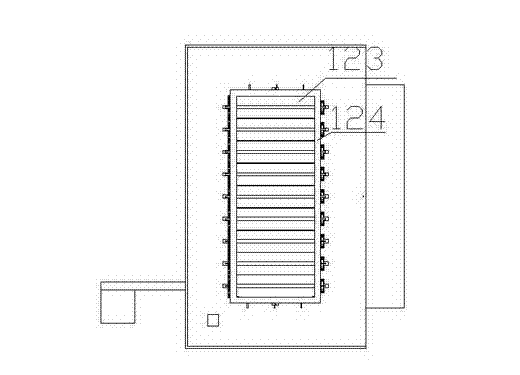

[0017] A biomass dry distillation and drying device, characterized in that it includes a vertical drying tower 1, a dry distillation reactor feed device 2, a dry distillation reactor 3, a dry distillation reactor gas collection and utilization system 4, and a combustible gas combustion system 5. The dry distillation reactor is composed of drainage device 6, carbon cabinet 7, carbon discharge pool 8, and remote control system 9. The vertical drying tower 1 is connected with the feed device 2 of the dry distillation reactor, the feed device 2 of the dry distillation reactor is connected with the dry distillation reactor 3, and the dry distillation reactor 3 is respectively connected wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com