Preparation method for shaping paper used for cigarette filter tip rod

A cigarette filter tip and molding paper technology, which is applied in papermaking, textiles and papermaking, natural cellulose pulp/paper, etc., can solve the problems of identifying genuine and fake cigarettes, harming consumers' interests, and losing national interests. High affinity, small difference in thermodynamic properties, and the effect of reducing harmful substances

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

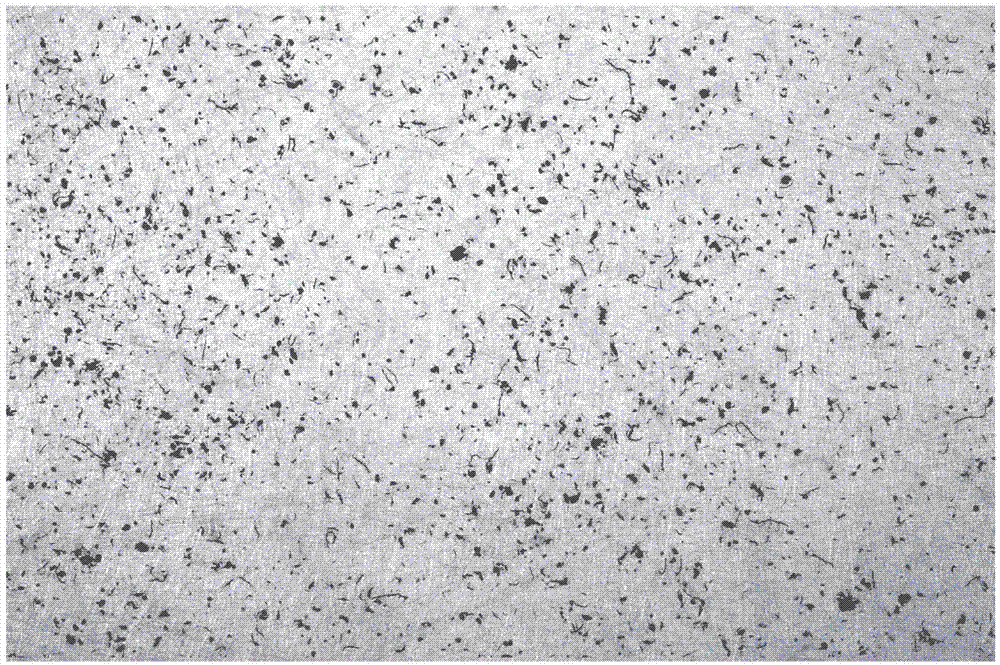

[0021] Select broad-leaved wood chips and coniferous wood chips, the size of the hard-leaved wood chips and the soft-leaved wood chips is 5mm×10mm×25mm~10mm×20mm×50mm, and mix them uniformly according to the ratio of 8:2; after washing, Steaming, heating, and pressing process, fully soften and separate the mixed wood chips to obtain wood pulp fibers, and bleach, screen and beat the wood pulp fibers to obtain pulp pulp; after heating the pulp pulp to 40~50°C, add 3% of the tobacco fiber is put into the beater for beating, and the specific pressure of beating is 5Kg / m 2 , to obtain pulp containing tobacco leaf fibers; add 1% NaOH as an additive, 15% CaCO 3 After being used as a filler, it is sent to the head box and wire section of the paper machine, and then squeezed, dried, coiled, cut, and packaged to obtain the anti-counterfeit cigarette filter rod molding paper of the present invention.

Embodiment 2

[0023] Select broad-leaved wood chips and coniferous wood chips, the size of the broad-leaved wood chips and the described coniferous wood chips is 5mm × 10mm × 25mm ~ 10mm × 20mm × 50mm, and mix uniformly according to the ratio of 7:3; after washing, Steaming, heating, and pressing process, fully soften and separate the mixed wood chips to obtain wood pulp fibers, and bleach, screen and beat the wood pulp fibers to obtain pulp pulp; after heating the pulp pulp to 40~50°C, add 30% of the tobacco fiber is put into a beater for beating, and the specific pressure of beating is 16Kg / m 2 , to obtain pulp containing tobacco leaf fibers; add 1.5% NaOH as an additive, 20% CaCO 3 After being used as a filler, it is sent to the head box and wire section of the paper machine, and then squeezed, dried, coiled, cut, and packaged to obtain the anti-counterfeit cigarette filter rod molding paper of the present invention.

Embodiment 3

[0025] Select broad-leaved wood chips and coniferous wood chips, the size of the hard-leaved wood chips and the soft-leaved wood chips is 5mm×10mm×25mm~10mm×20mm×50mm, and mix uniformly according to the ratio of 6:4; after washing, Steaming, heating, and pressing process, fully soften and separate the mixed wood chips to obtain wood pulp fibers, and bleach, screen and beat the wood pulp fibers to obtain pulp pulp; after heating the pulp pulp to 40~50°C, add 10% of the tobacco fiber is put into a beater for beating, and the specific pressure of beating is 8Kg / m 2 , to obtain pulp containing tobacco leaf fibers; add 2% NaOH as an additive, 25% CaCO 3 After being used as a filler, it is sent to the head box and wire section of the paper machine, and then squeezed, dried, coiled, cut, and packaged to obtain the anti-counterfeit cigarette filter rod molding paper of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com