Device for limiting and protecting anchoring end of vertical steel strand

A technology of limit protection and steel strands, which is applied to bridge parts, bridges, buildings, etc., can solve problems such as inability to stick and fix, steel strands and clips slipping, and limited strength of the tape, so as to prevent the grout from entering The tunnel, the connection is tight and no slurry leakage, the effect of convenient and quick installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

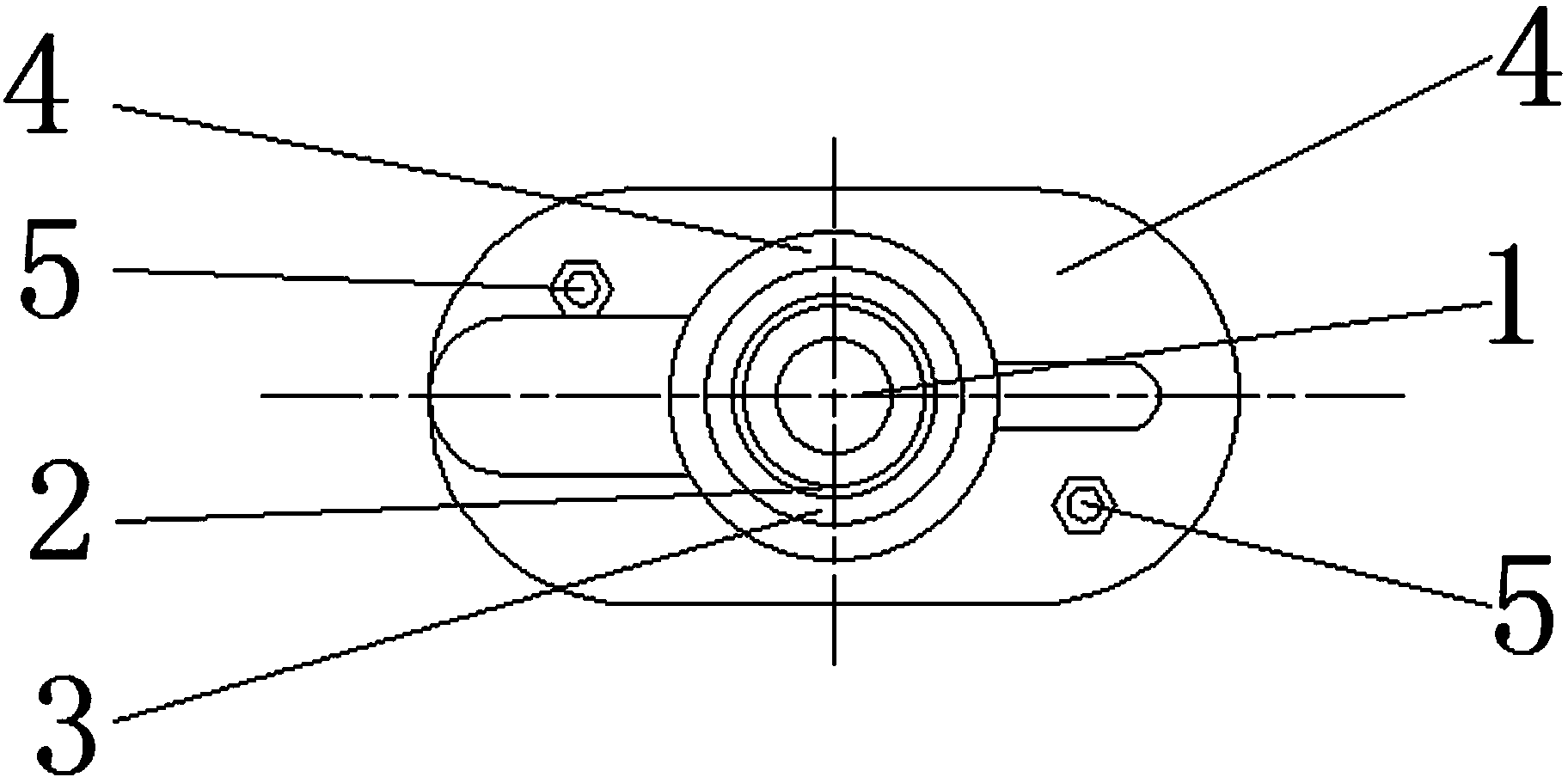

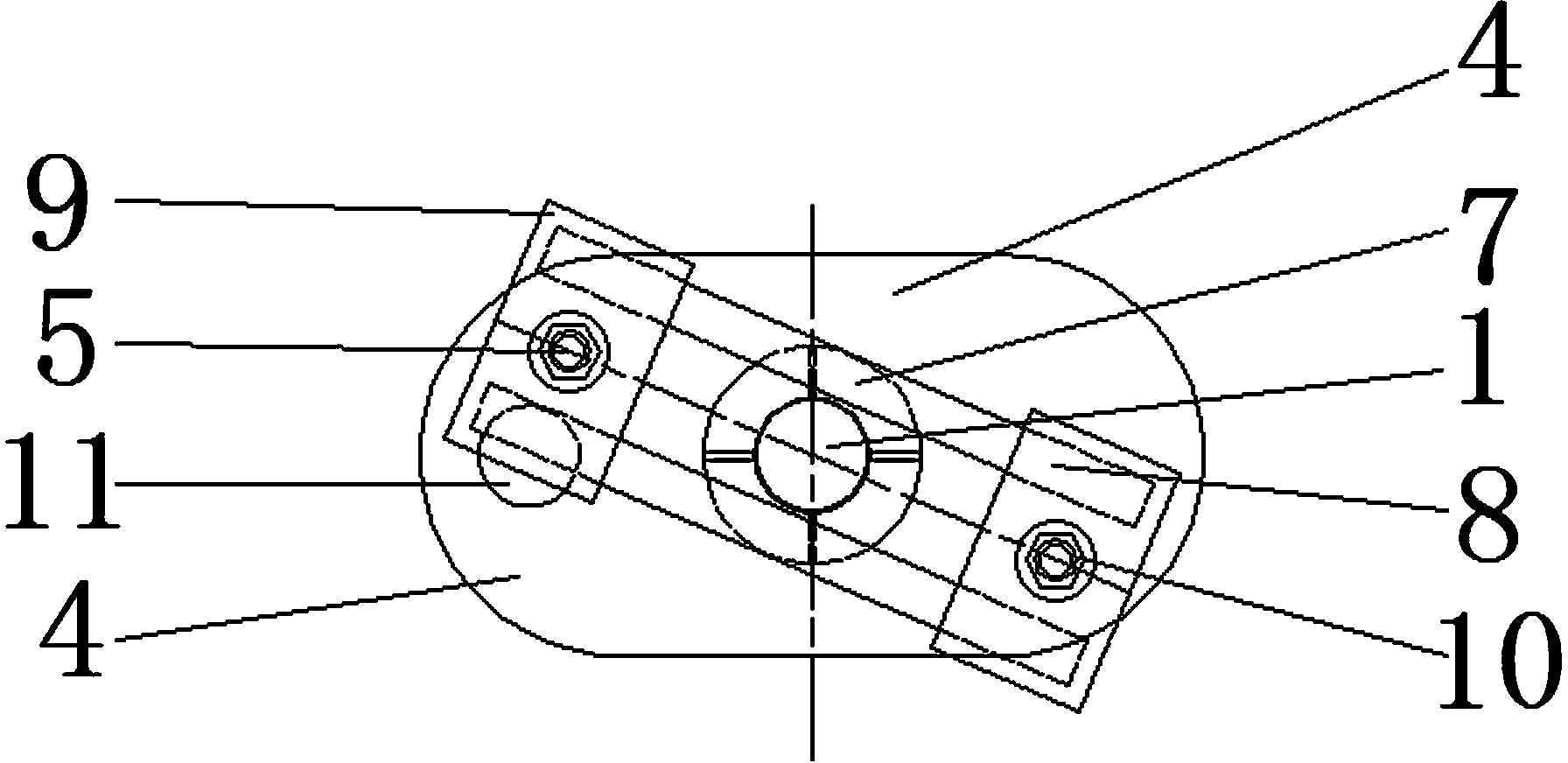

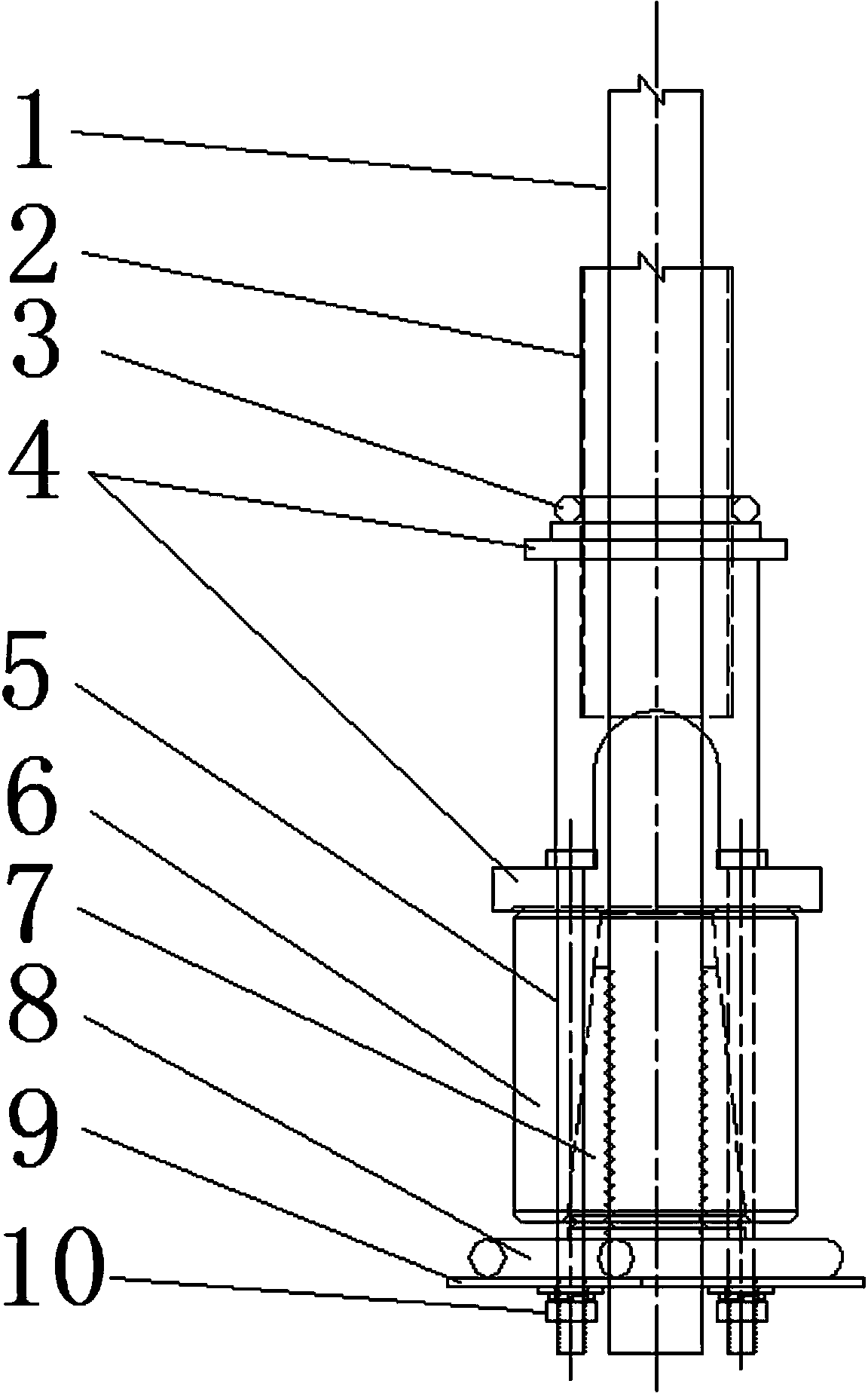

[0022] like figure 1 , figure 2 , image 3 and Figure 4 Shown: a limit protection device for the anchorage end of a vertical steel strand, including a steel strand 1, an iron pipe 2, an anchor pad 4, an anchor cup 6 and a clip 7, and the anchor pad 4 is provided with a grouting hole 11 ; Also includes a limit connecting plate 9, a limit rod 5 and a fastening nut 10; see Figure 5 , Figure 6 and Figure 7 : the limit connecting plate 9 is two steel plates 13 arranged on the left and the right, and two retaining rods 8 are welded above the two steel plates 13, the distance between the two retaining rods 8 and the distance between the two steel plates 13 form a through hole 12, and the two retaining rods The 8 spacing is smaller than the outer edge of the bottom of the clip 7 and greater than the outer edge of the steel strand 1, the steel strand 1 passes through the through hole 12, and the bottom of the clip 7 is stuck on the top of the two retaining rods 8 to limit the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com