Air purifier with automatic working mode switching function and purification method of air purifier

An air purifier, working mode technology, applied in heating mode, climate sustainability, space heating and ventilation, etc., can solve problems such as waste, unreasonable utilization of resources, and inability to realize automatic switching.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

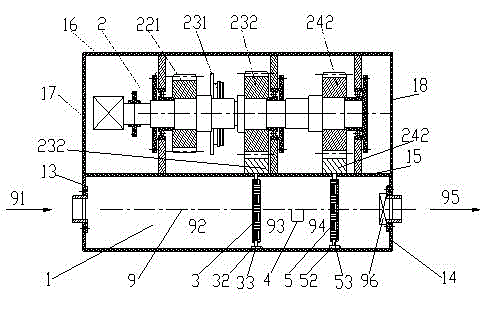

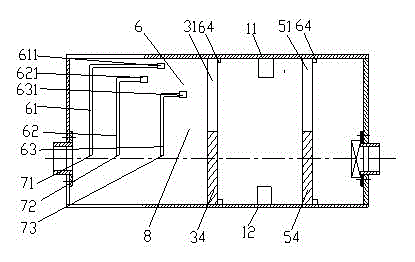

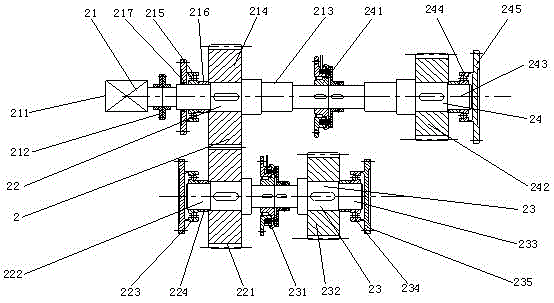

[0028] Such as figure 1 , 2As shown, the air purifier is composed of a body 1, an automatic working mode switching device 2, a dust purification unit 3, a toxic and harmful gas purification unit 4, a carbon dioxide purification unit 5, and a detection and control device 6. The bottom of the body 1 is surrounded by the left and right panels 11 and 12 at both ends, and the front and rear panels 13 and 14 form a lower three-dimensional frame structure, and the body is divided into upper and lower parts by the middle plate 15 . The upper part of the body 1 is surrounded by an upper panel 16, front and rear panels 17 and 18 to form an upper three-dimensional frame structure. The working mode automatic switching device 2 is located at the top of the body 1 , and the dust purification unit 3 , toxic and harmful gas purification unit 4 , ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com