Calibration stand of tension monitoring stress hinge pin for cable disengaging hook

A stress pin and tension technology, applied in the direction of force/torque/work measuring instrument calibration/testing, measuring devices, instruments, etc., to achieve the effect of overcoming the pulling force of the uncoupling hook and monitoring the stress pin, easy to use and simple to operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

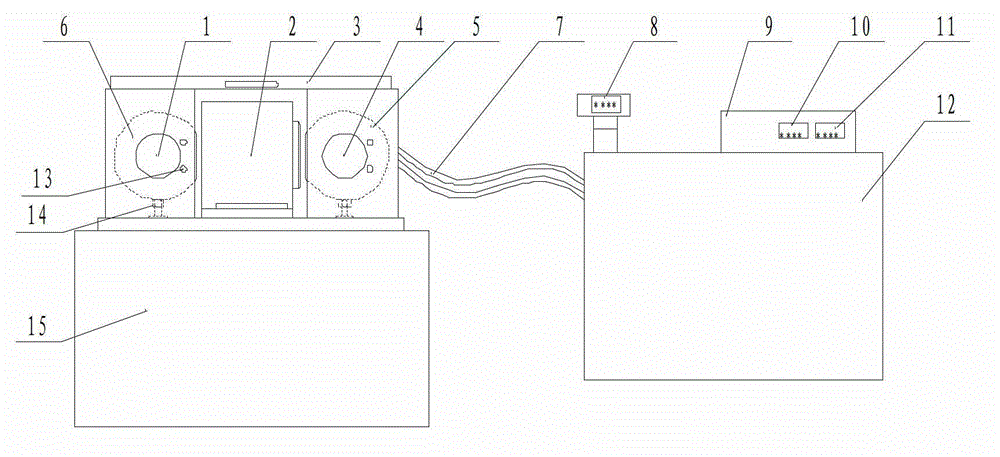

[0014] The present invention will be further described below in conjunction with the accompanying drawings.

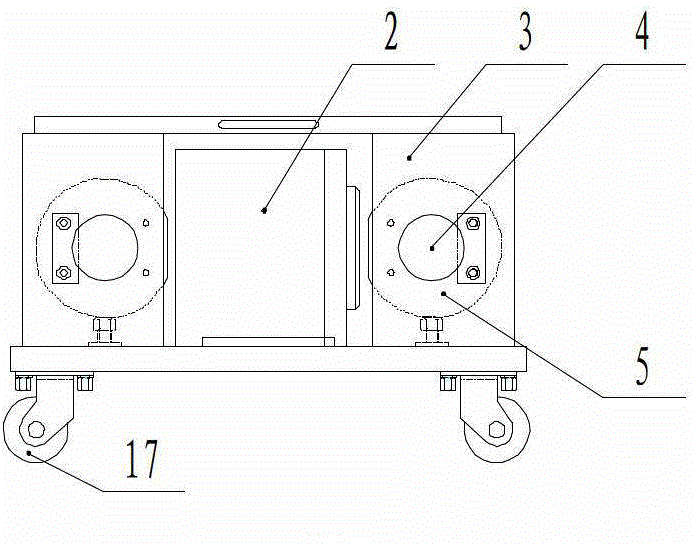

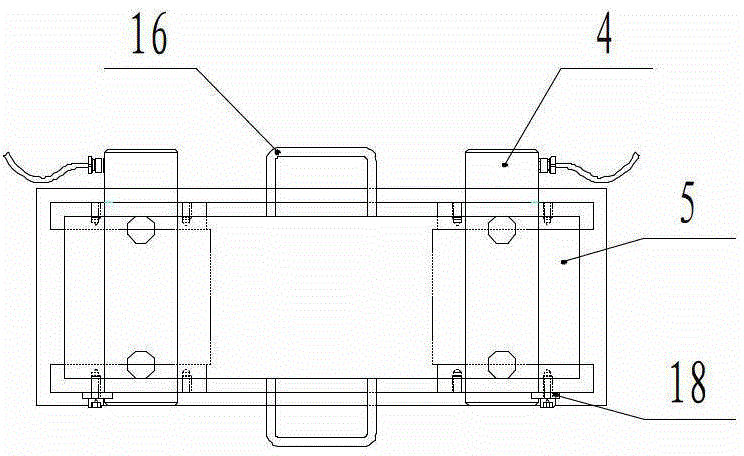

[0015] figure 1 The tension monitoring stress pin correction table for the cable hook shown in , includes a correction frame 3, a hydraulic station 12 provided with a hydraulic pressure display gauge 8, and the correction frame 3 is provided with an oil cylinder 2 connected to the hydraulic station 12 through the oil pipe 7, and On both sides of the oil cylinder 2 on the correction frame 3, the shaft sleeve A 5 and the shaft sleeve B 6 are respectively installed, and the shaft sleeve A 5 and the shaft sleeve B 6 are respectively provided with a locking plate adjustment port 13; the standard shaft 4 is placed on the shaft sleeve A 5 Inside and connected with display and adjustment meter box 9 by wire, the bottom of axle sleeve first 5 and axle sleeve second 6 is provided with axle sleeve adjusting bolt 14 respectively.

[0016] The correction frame 3 in the present inv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com