Shale gas reservoir recovery simulation experimental device

A simulation experiment device and technology of shale gas reservoirs, applied in the field of shale gas reservoir mining simulation experiment devices, can solve the problem of few mining mechanisms

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

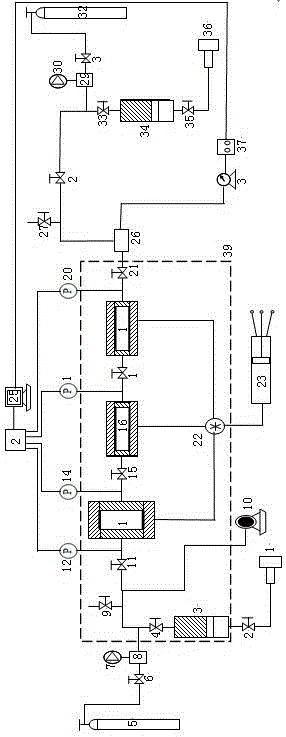

[0020] like figure 1 As shown, the present invention provides a simulation experiment device for simulating shale gas reservoir exploitation, including a high-pressure gas source system, an injection system, a model system, a constant temperature box system, a back pressure system and a data acquisition system.

[0021] The high-pressure gas source system mainly includes two parts, high-purity CH 4 / CO 2 / He high-pressure gas cylinder 5 is sequentially connected to valve 6, booster pump 8, and intermediate container 3 of the injection system; N 2 The high-pressure cylinder 32 is sequentially connected to the valve 31, the booster pump 29, and the intermediate container 34 of the back pressure system. The booster pumps (8, 29) are connected to the air compressors (7, 30), one end of the booster pumps (8, 29) is connected to the high-pressure gas cylinders (5, 32), and the other end is connected to the intermediate container (3, 34) , where the high-pressure gas cylinders (5,...

example 2

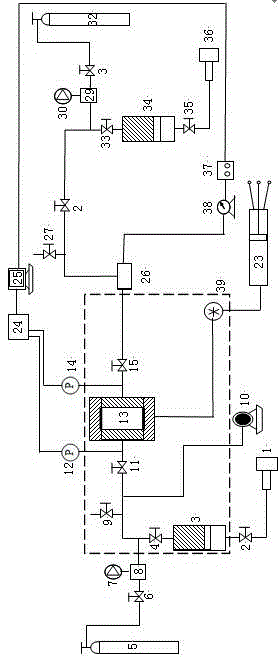

[0039] like figure 2As shown, the present invention also provides a schematic diagram of a shale gas adsorption / desorption experimental device, including a high-pressure gas source system, an injection system, a model system, a constant temperature box system, a back pressure system and a data acquisition system. The high-pressure gas source system, injection system, constant temperature box system, back pressure system and data acquisition system are partly the same as the shale gas reservoir mining simulation experiment device described in Example 1, and will not be described in detail. The inlet valve 11 in the model system is connected to the flat model rock core holder 13 and the outlet valve 15 in turn, the pressure sensor 12 and the pressure sensor 14 are respectively connected to the inlet and outlet of the flat model rock core holder 13, and the inlet valve 11 is connected to the injection system The intermediate container 3 is connected, the inlet valve 11 is connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com