Drilling electric shock alarm system for trenchless drilling machine

An alarm system and non-excavation technology, applied in drilling equipment, earthwork drilling, drilling equipment and methods, etc., can solve problems such as personnel injury and project loss, and achieve the effects of convenient installation and debugging, low cost and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

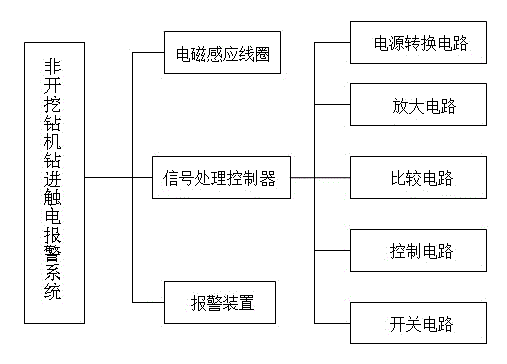

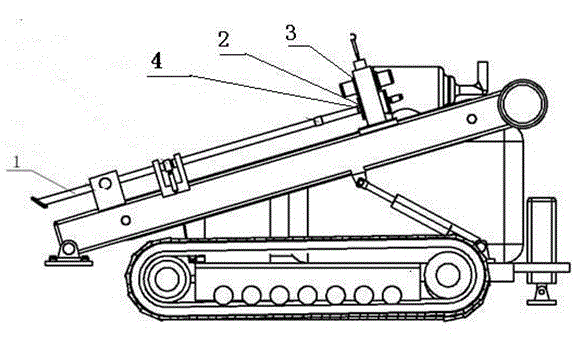

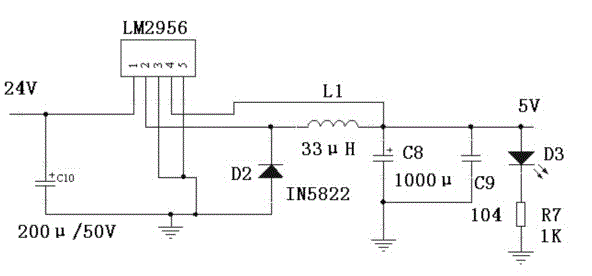

[0026] Embodiment 1: The present invention provides a kind of non-excavation drilling rig drilling electric shock alarm system, its structure is as follows figure 1 . It includes an electromagnetic induction coil 2, a signal processing controller and an alarm device. The electromagnetic induction coil 2 is installed at the power head front cover 4 of the power head 3 of the trenchless drilling rig, such as figure 2 . The electromagnetic induction coil 2 is packaged in a completely closed plastic shell, and a resistor is connected in parallel between the two output lines of the electromagnetic induction coil 2; the resistance connected in parallel in this example is 100Ω. Described signal processing controller is a small microprocessing system, is provided with power conversion circuit, amplifying circuit, comparison circuit, control circuit and switching circuit; The electromagnetic induction coil 2 generates an induced electromotive force signal to amplify. The comparison ...

Embodiment 2

[0034]Embodiment 2: The structure of the non-excavation drilling rig drilling electric shock alarm system of the present invention is as in embodiment 1, the difference is that the electromagnetic induction coil 2 is installed on the drill pipe 1 protection short of the non-excavation drilling rig power head 3, in the electromagnetic induction The resistance connected in parallel between the two output lines of coil 2 is 50Ω. The working process of the trenchless drilling rig drilling electric shock alarm system of the present invention is as follows: Figure 9 , when the non-excavation drilling rig starts to work, and when the drill rod gets an electric shock during the drilling of the trenchless drilling rig, an induced electromotive force signal is generated in the electromagnetic induction coil 2, and the induced electromotive force signal is transmitted to the voltage signal amplification circuit in the signal processing controller, and the voltage signal is amplified The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com