Packing technique for LED lamp beads

A technology of LED lamp beads and packaging technology, applied in electrical components, circuits, semiconductor devices, etc., can solve the problems of cyan, difficult to meet the specific requirements of warm light in high-end places, and light cyan, and achieve high color purity and bright colors. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be described in more detail below in conjunction with the accompanying drawings and embodiments.

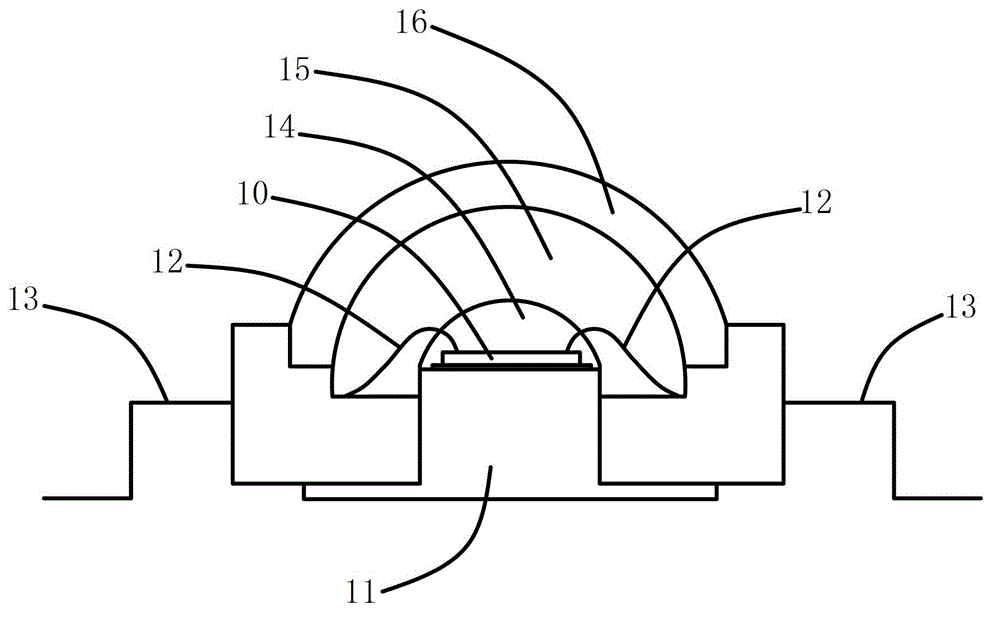

[0013] The invention discloses a packaging process for LED lamp beads, such as figure 1 As shown, the LED lamp bead made by this packaging process includes a bracket 11, an LED chip 10 pasted on the bracket 11 and two pins 13, and the two electrodes of the LED chip 10 are separated by two gold wires 12. Connected to two pins 13 , the LED chip 10 is coated with a phosphor layer 14 , the phosphor layer 14 is covered with a silica gel layer 15 , and the silica gel layer 15 is covered with a plastic lens 16 .

[0014] The packaging process of the LED lamp bead includes the following steps:

[0015] A. Paste the LED chip 10 on the support 11 with insulating glue and dry it;

[0016] B, the gold wire 12 is welded between the electrode of the LED chip 10 and the pin 13;

[0017] C. Mix and stir red phosphor, green phosphor and yellow phosphor evenly....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com