Method for improving problem of light spots of high-power light-emitting diode (LED)

A high-power, LED chip technology, applied in the direction of electrical components, electric solid devices, circuits, etc., can solve the problems of dust pollution, difficult preparation, complex process, etc., and achieve the effect of increasing the output rate, small influence, and high light output rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

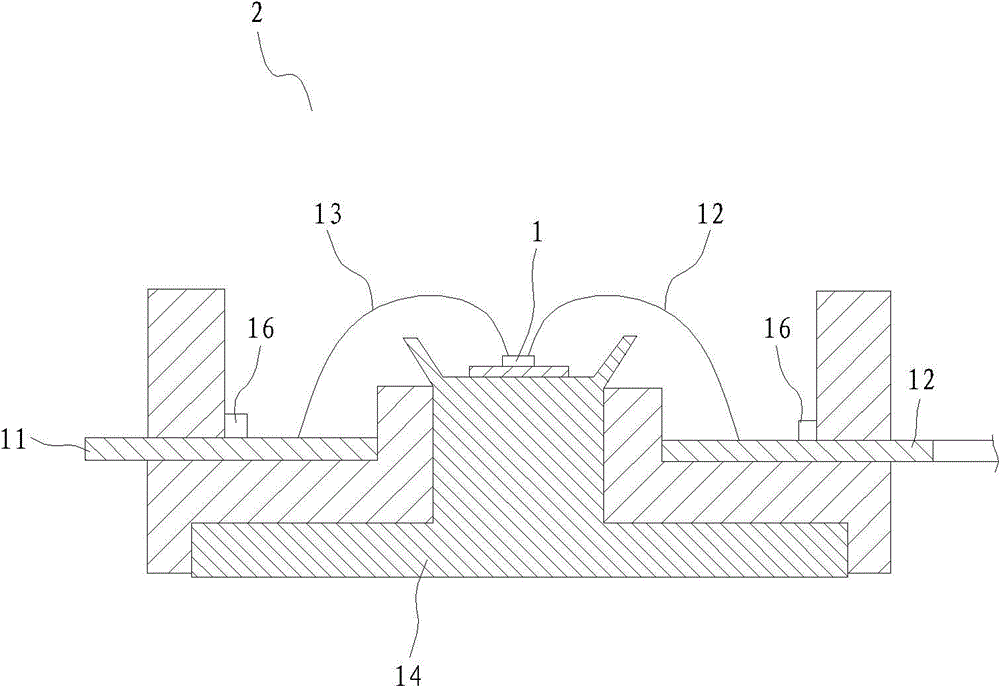

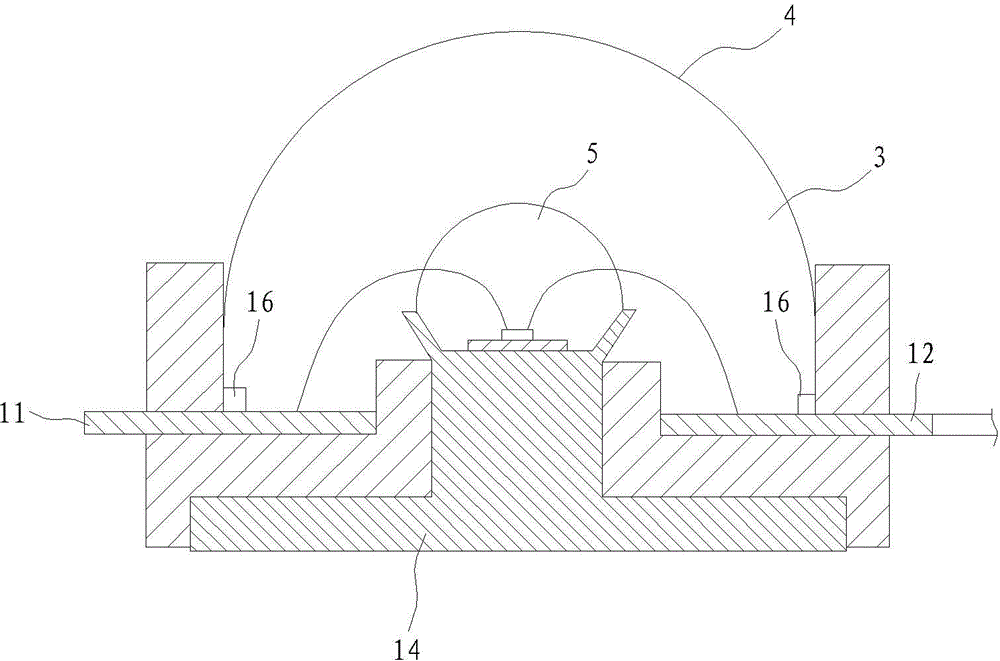

[0020] The present invention will be further described in conjunction with the accompanying drawings and specific embodiments.

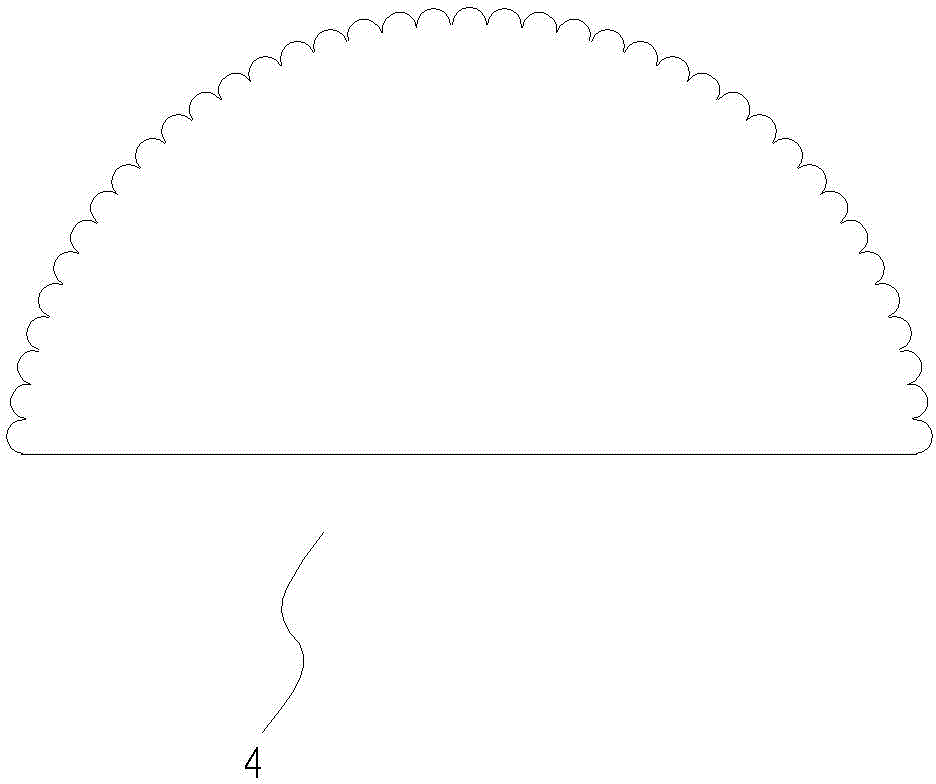

[0021] A method for improving the light spot of a high-power LED of the present invention is realized by uniformly spreading transparent particles with a polyhedral structure in the silicone layer and / or the fluorescent glue layer in the existing LED packaging structure. The transparent particles account for 2%-10% by weight of the filler. Then the filling glue accounts for 90%-98% by weight. Specifically, the transparent particles are PMMA transparent particles in the shape of concave lenses, SiO in the shape of 3 to 8 faces 2 Mixed particles of transparent particles and PC transparent particles in the shape of a polyhedron larger than 8 sides; the SiO 2 The transparent particles account for 0.6%-3.7% by weight of the filler, the PC transparent particles account for 0.2%-2.3% by weight of the filler, and the PMMA transparent particles account for 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com