Stack package plate for preventing condensation in fuel cell stack

A technology for fuel cell stacks and packaging boards, applied to fuel cell components, fuel cells, fuel cell additives, etc., can solve problems such as the inability to fundamentally solve the threat of liquid water, and achieve the effect of reducing water vapor content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

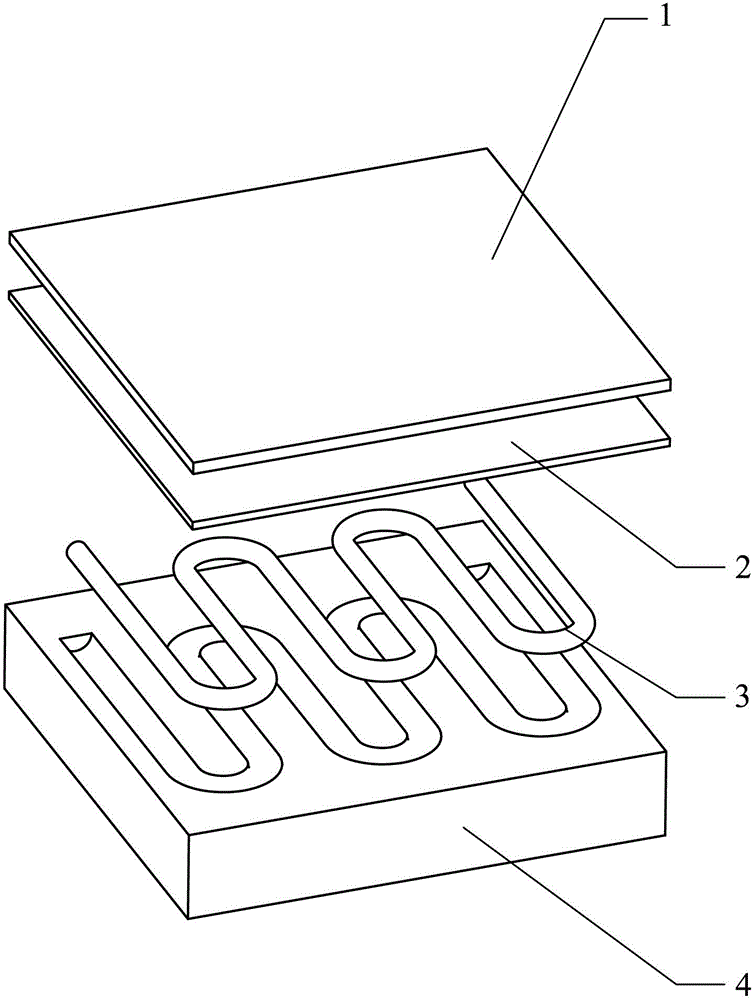

[0021] Use a benzene board as the insulation layer 4; use a stainless steel plate as the support layer 2; use absorbent paper as the water-absorbing layer 1, and the stack packaging board formed is used to package the stack. The layers are glued together to form a board.

Embodiment 2

[0023] Use an airgel silica pad as the insulation layer 4, and arrange heating elements 3 for heat preservation in the insulation layer. The heating elements 3 are resistance wires; use an aluminum plate as the support layer 2; use absorbent paper as the water absorption layer 1 , the stack package board is used to package the stack. The layers are glued together to form a board.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com