Net hauler provided with rubber ring traction wheel

A technology of rubber rings and traction wheels, which is applied in the field of fishing machinery, can solve the problems of inconvenient rubber installation, complex structure, and easy slippage, and achieve the effects of saving use costs, reducing labor intensity, and reducing loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to describe the technical content, structural features, achieved goals and effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

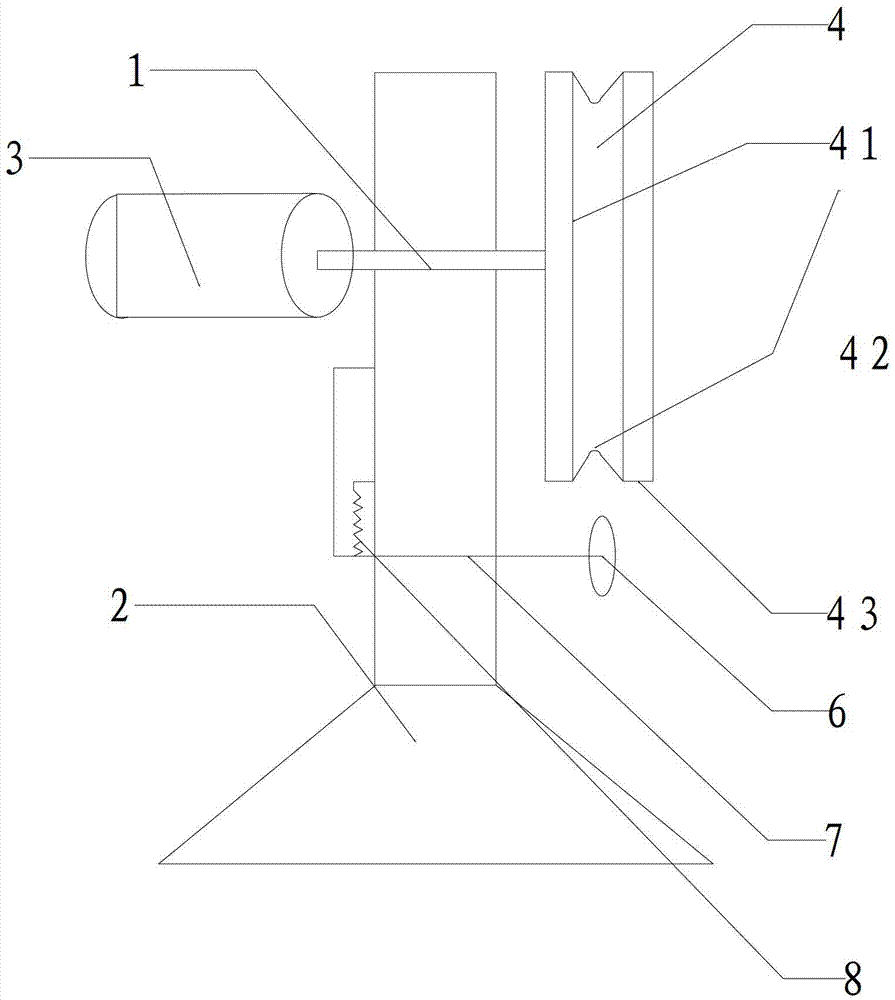

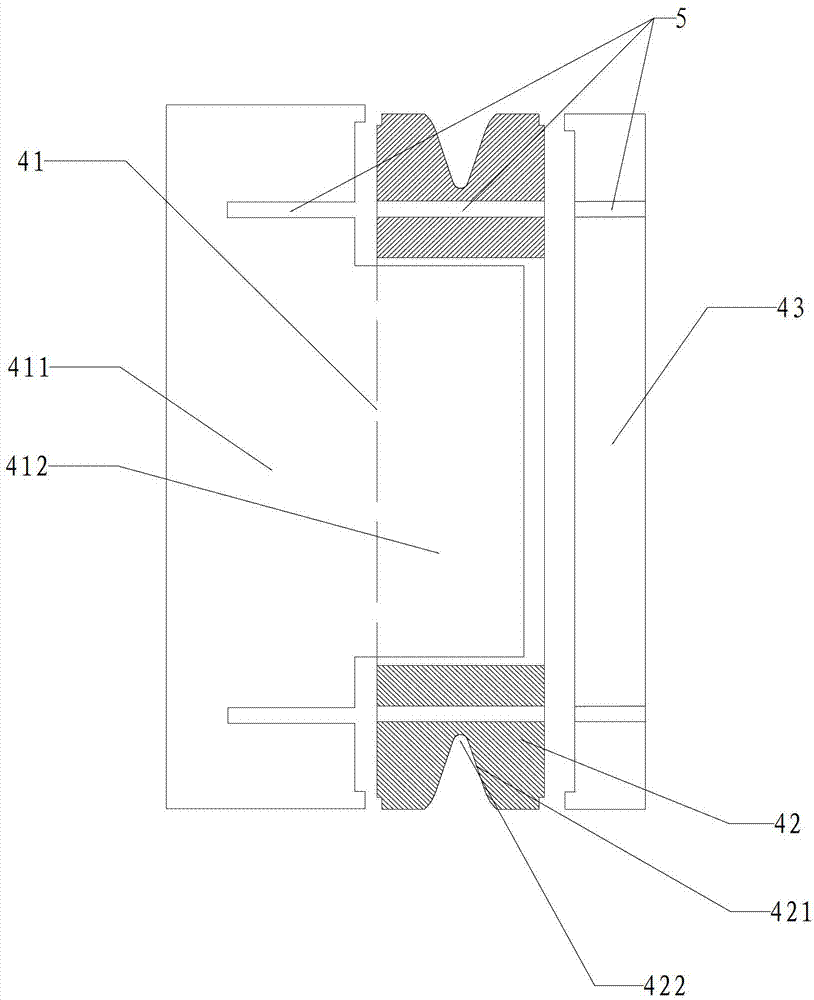

[0022] see figure 1 as well as figure 2 , one embodiment of the present invention is to provide a kind of net lifting machine that is provided with rubber ring traction wheel, comprises machine head 1, machine base 2, and described machine head 1 is installed on the machine base 2, and described machine head 1 comprises power Device 3 and traction wheel 4, traction wheel 4 is installed on one side of machine base 2, and power unit 3 is installed on the other side, and described power unit 3 can be electric motor, engine, hydraulic motor etc. The traction wheel 4 is driven to rotate by the power unit 3, and a rubber ring 42 is embedded on the traction wheel 4, and the rubber ring 42 is integrally formed, and the surface of the rubber ring...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com