AGC (Automatic Gain Control) method capable of calculating thickness based on second flow

A control method and second flow technology, applied in the direction of rolling mill control devices, metal rolling, manufacturing tools, etc., can solve the problem of strip breakage in the first stand, loss of tension at the entrance, large fluctuations in the thickness of the strip steel at the exit of the first stand, etc. problems, to achieve the effect of improving control accuracy and reducing production accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described through the embodiments below in conjunction with the accompanying drawings.

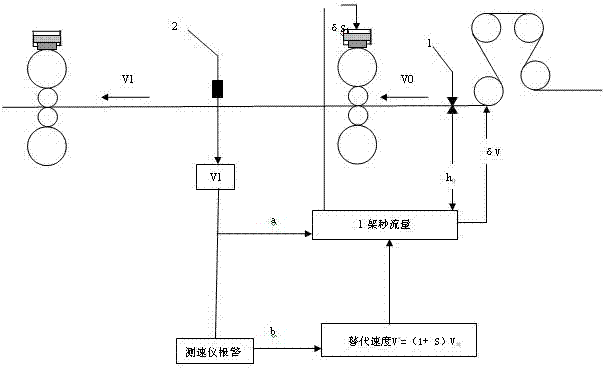

[0016] figure 1 It is the control principle diagram of the second flow AGC system that replaces the velocity gauge to calculate the thickness in the embodiment of the present invention. The entrance of the first stand of the continuous rolling mill is equipped with an IRM thickness gauge, and the exit is equipped with a laser velocity gauge. The laser velocity gauge is involved in the measurement of the speed in the normal production process The control of the second flow AGC is shown in path a; when the laser velocimeter cannot be used normally, the method of measuring the speed instead of the laser velocimeter is adopted, and the method of path b is used to ensure the normal closed-loop control of the second flow AGC control.

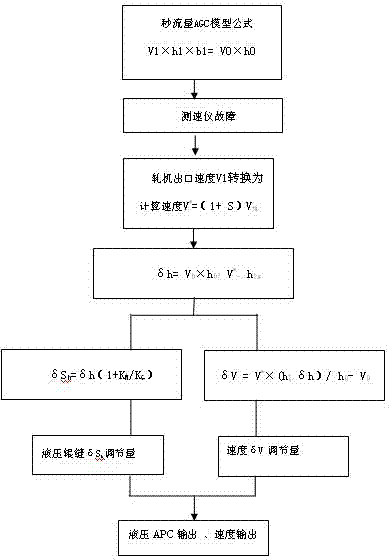

[0017] figure 2 It is the flow chart of the AGC control method for calculating the thickness in seconds according t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com