Conveying device for connecting elements and pulling-on piece assembler using conveying device

A technology of conveying device and connecting piece, applied in the directions of feeding device, positioning device, storage device, etc., can solve the problem of low production efficiency of automatic pull tab assembly machine, and achieve the effect of high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

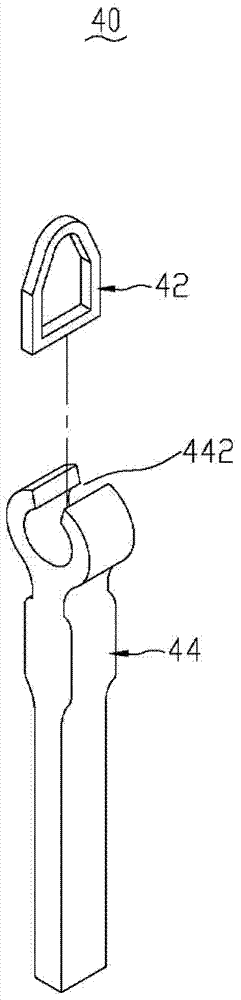

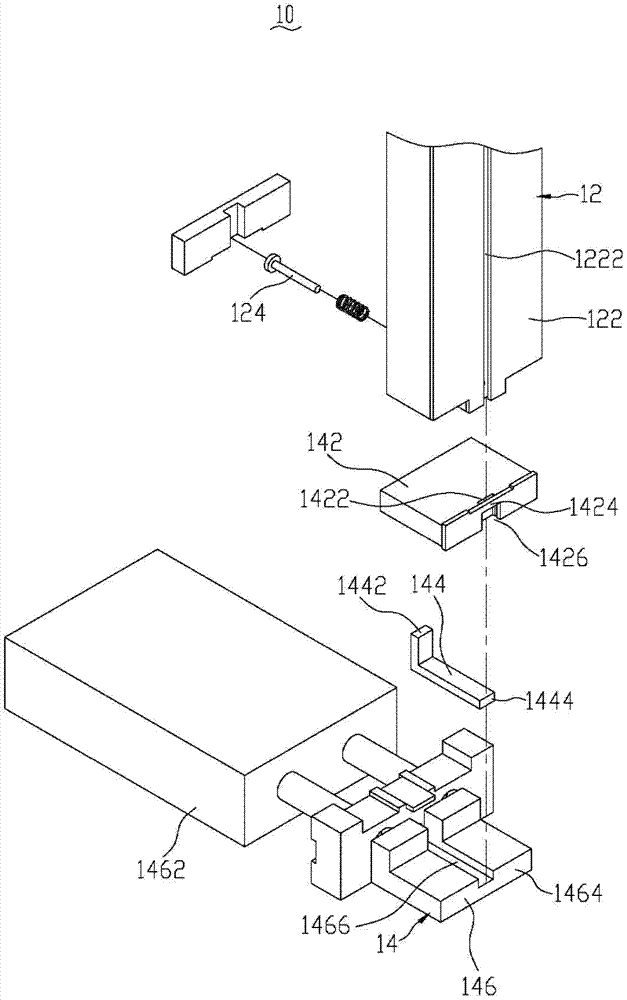

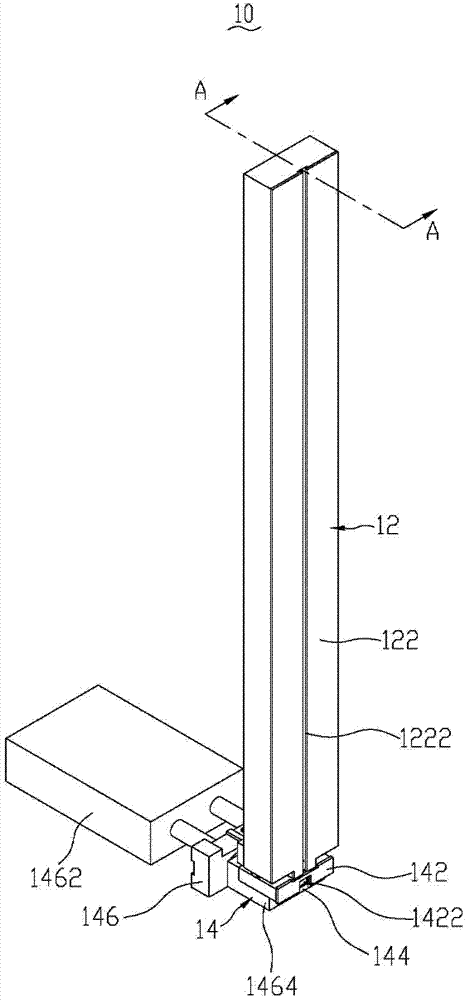

[0034] Please refer to figure 1 and figure 2 , the connector conveying device 10 is used to automatically and accurately place the connector 42 into the opening 442 of the handle 44 . The connector delivery device 10 includes a connector alignment mechanism 12 and a connector guide mechanism 14 . The connector arranging mechanism 12 is used to sort and orient a plurality of connectors 42 , and transport the connectors 42 one by one into the connector guide mechanism 14 in a certain orientation. The connecting piece guiding mechanism 14 is used for accommodating the connecting piece 42 and delivering the connecting piece 42 into the opening 442 of the handle 44 at a predetermined orientation.

[0035] The connector arrangement mechanism 12 includes a delivery block 122 and a reciprocating and slidable retaining pin 124 . The front side of the conveying block 122 is provided with a connecting member conveying slideway 1222 , and the connecting member conveying slideway 1222 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com