Automatic pipe cutting machine feeding device

A pipe cutting machine and automatic technology, which is applied in the field of automatic pipe cutting machine feeding devices, can solve the problems that the working continuity and stability of the automatic pipe cutting machine cannot be guaranteed, it is difficult to accurately control the quantity and transfer timing of pipes, and the equipment cost is high. Simple structure, high production efficiency, and the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

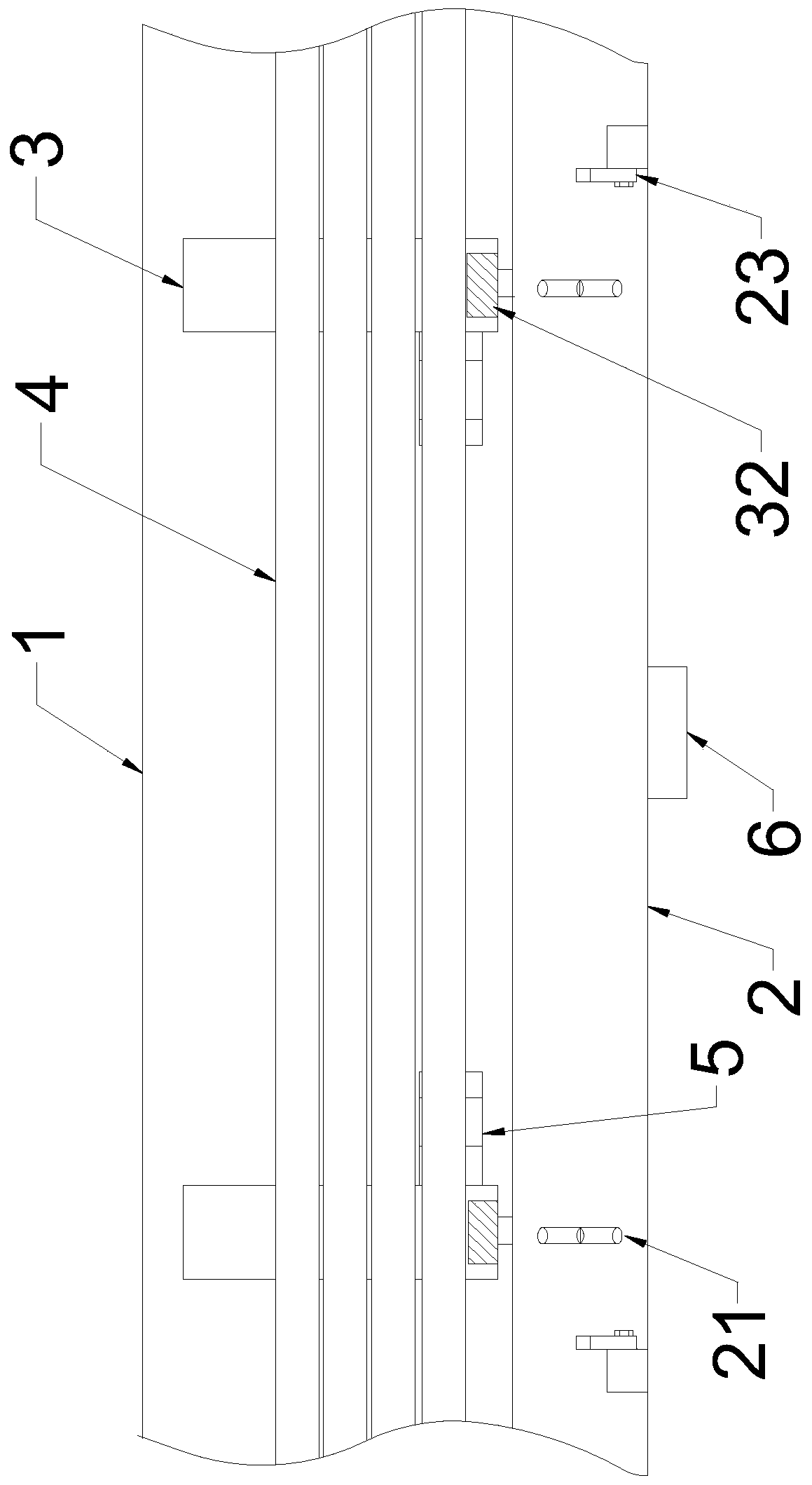

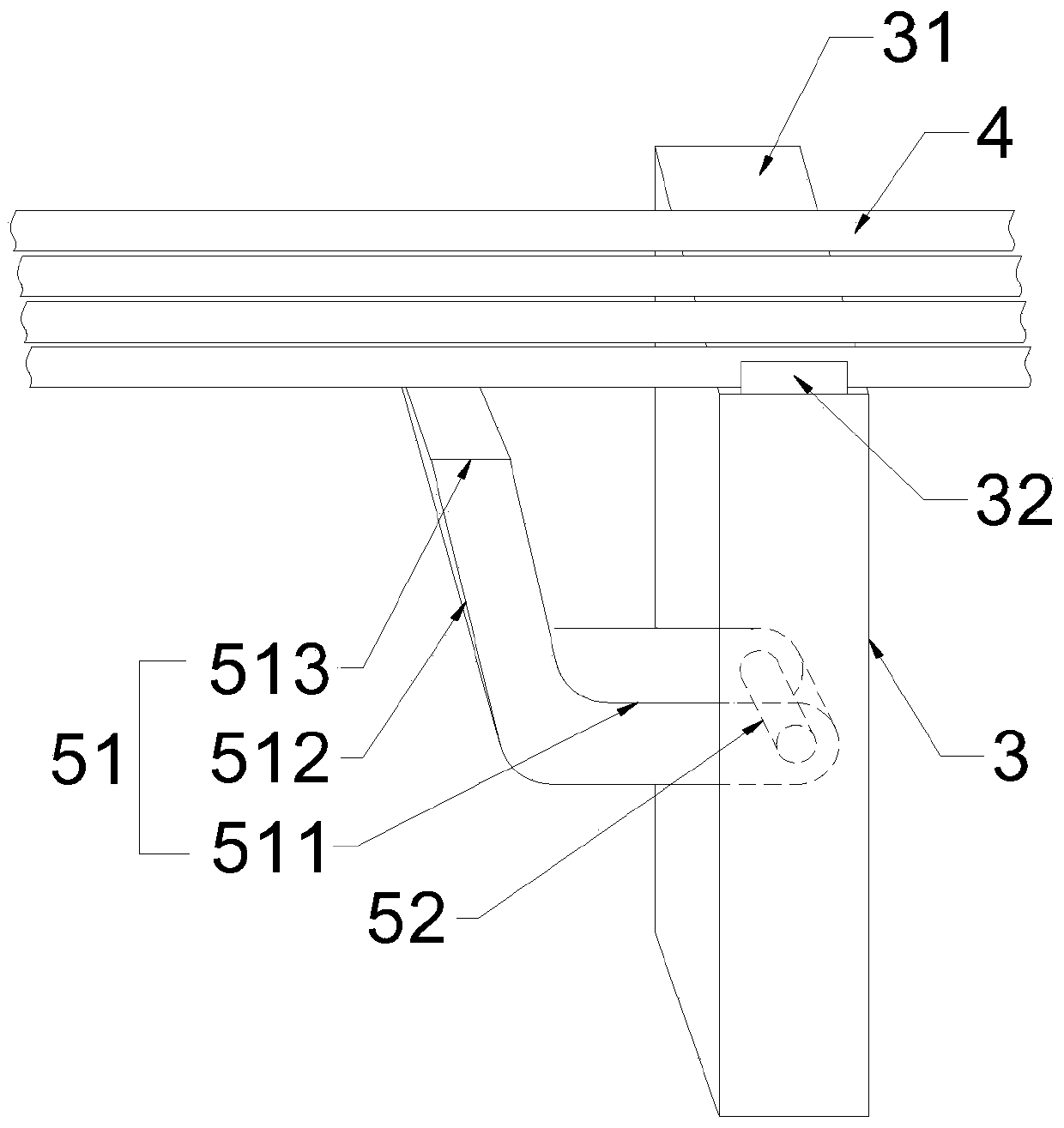

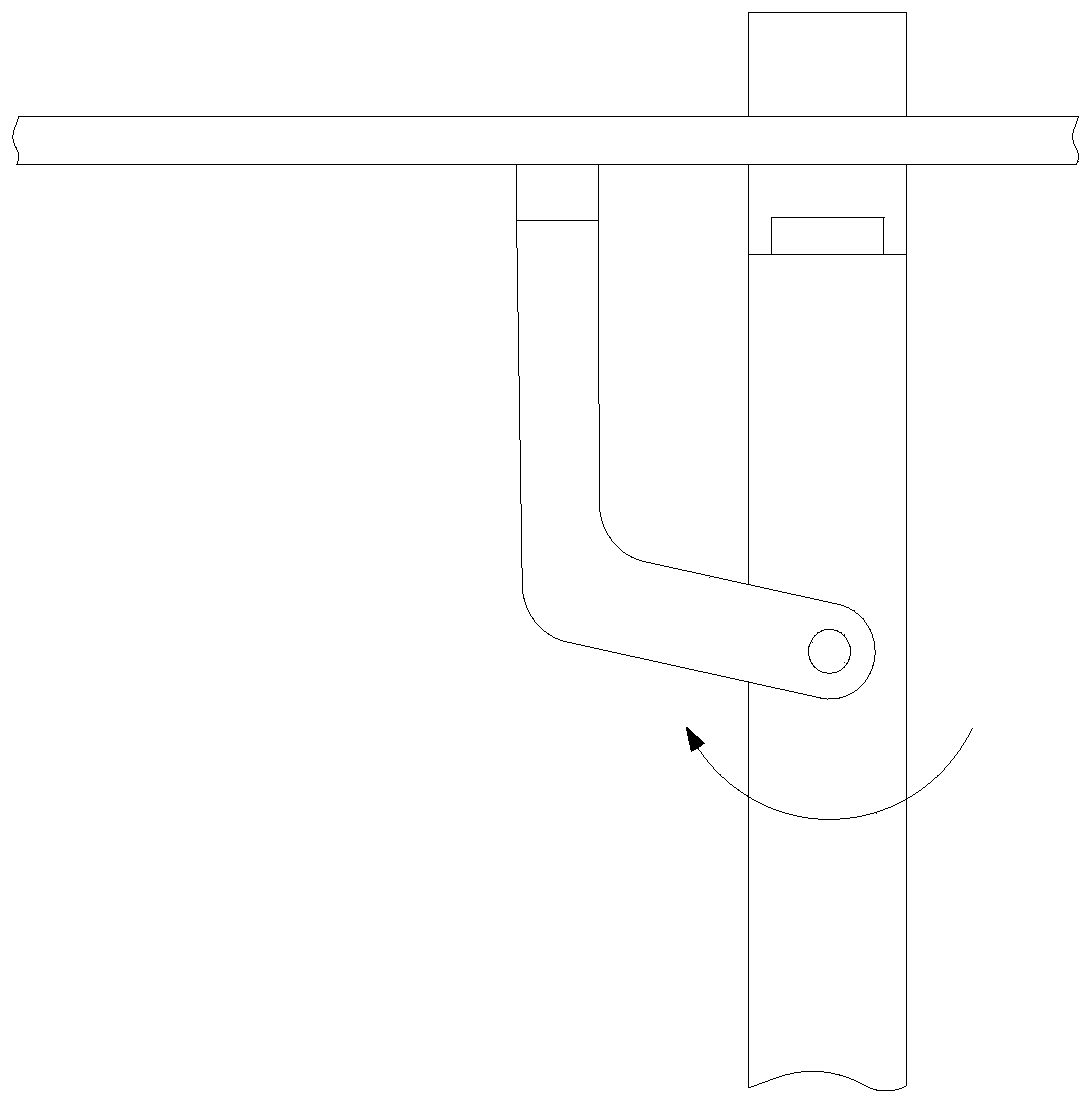

[0021] Such as Figure 1 to Figure 3 As shown, a feeding device for an automatic pipe cutting machine includes a machine platform 1, a conveying platform 2 and two storage racks 3 are arranged above the machine platform 1, the conveying platform 2 is located below the material storage rack 3, and the upper conveying platform 2 is spaced There are at least two branch pipe racks 21 for supporting the bearing tubes 4; the storage racks 3 are arranged at intervals, and the storage racks 3 include a stock top 31 inclined to the conveying table 2 side, and a plurality of bearing tubes 4 can temporarily Stored in the top of the stock 31, the end of the top of the stock 31 close to the conveying table 2 is provided with a limit block 32, the limit block 32 can resist the bearing tube on the bottom side, preventing the bearing tube from rolling down from the top of the stock 31 to the conveying table 2; the storage rack 3 is also provided with a jacking assembly 5, the jacking assembly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com