A fixed-length cutting equipment for industrial production of steel pipes

A cutting equipment, fixed-length technology, applied in metal processing equipment, shearing machine equipment, pipe cutting devices, etc., can solve the problems of low degree of automation and reduced production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

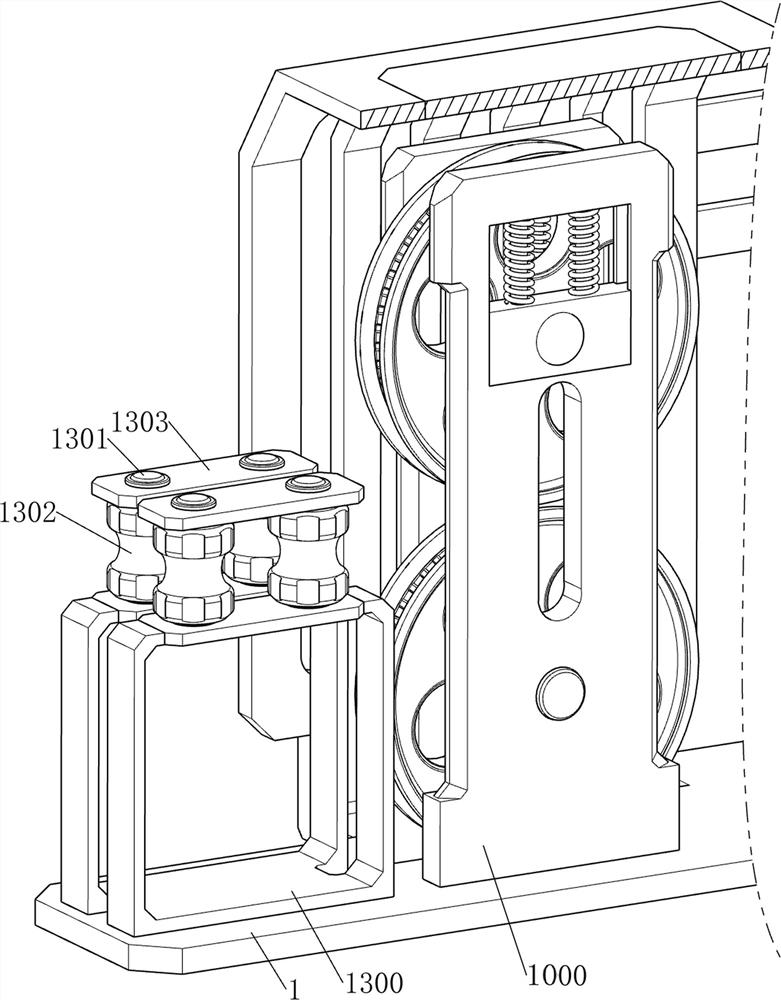

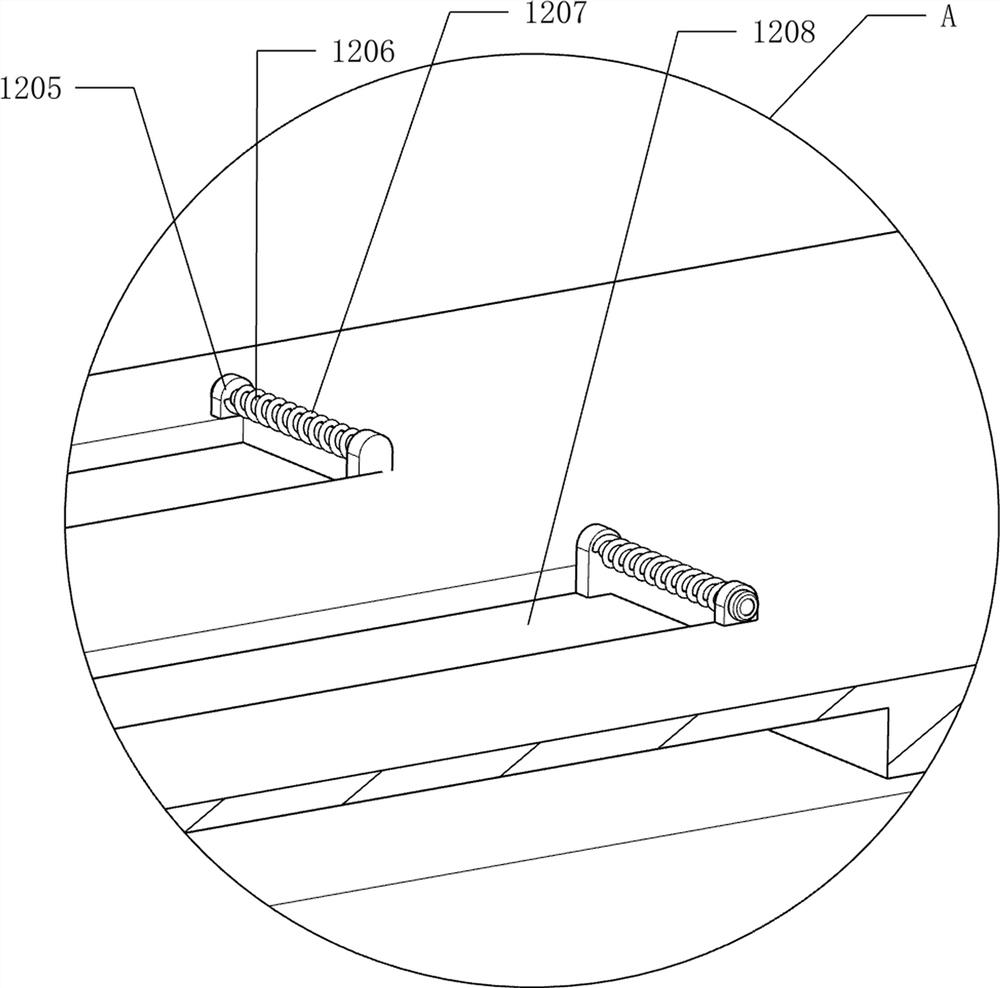

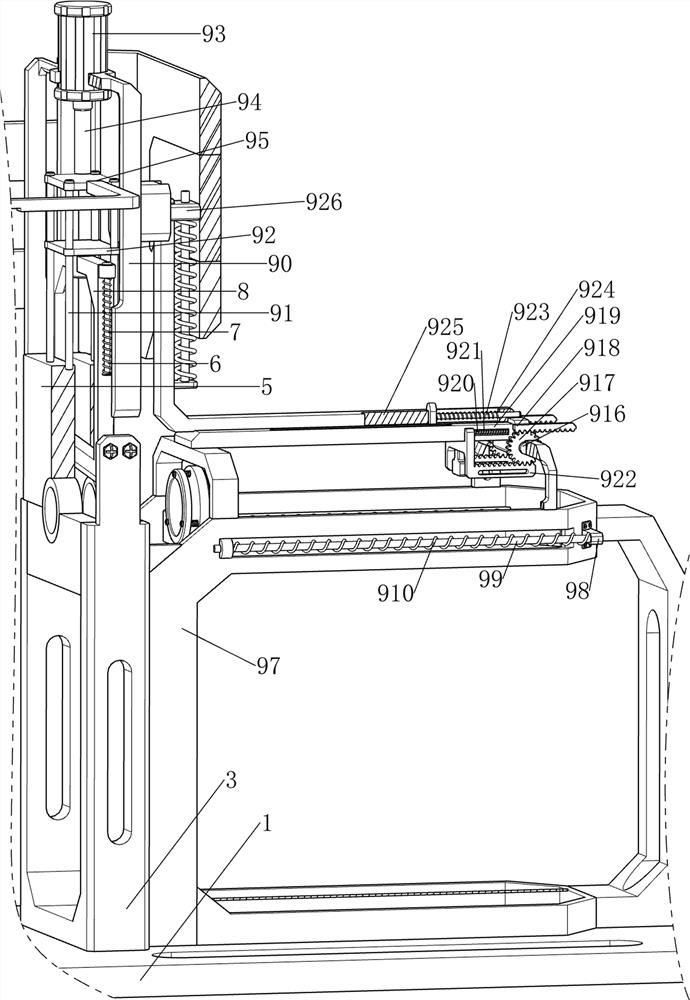

[0027] A kind of fixed-length cutting equipment for industrialized production of steel pipes, such as Figure 1-5 As shown, it includes a bottom plate 1, a protective plate 2, a first support frame 3, a backing plate 4, a guide block 5, a guide rod 6, a first spring 7, a guillotine 8, a pressing mechanism 9 and a feeding mechanism 10, and the bottom plate 1 A protective plate 2 is provided in the middle, a first support frame 3 is provided on the top right side of the bottom plate 1, a backing plate 4 is provided on the upper part of the first support frame 3, and a guide block 5 is provided on the top of the first support frame 3, and the top of the guide block 5 is symmetrical front and rear Guide rods 6 are provided, guillotines 8 are slidingly arranged between the guide rods 6, first springs 7 are arranged between the guillotines 8 and the guide rods 6, a pressing mechanism 9 is provided on the guide block 5, and a pressing mechanism 9 is provided on the bottom plate 1 Fee...

Embodiment 2

[0032] On the basis of Example 1, such as Figure 6-10 As shown, a power mechanism 11 is also included, and the power mechanism 11 includes a movable rod 1100, a second fixed block 1101, a seventh limit rod 1102, an eighth spring 1103, a fourth movable block 1104, a fifth movable block 1105, a limiter Position plate 1106, the eighth limit rod 1107, the ninth spring 1108, the second support plate 1109, the one-way gear 1110, the second gear 1111 and the third gear 1112, and the second lower pressing plate 95 is symmetrically provided with movable rods 1100 front and back, The middle part of the bottom plate 1 is symmetrically provided with a second fixed block 1101 front and back, and four seventh stop rods 1102 are arranged on the top of the second fixed block 1101, and fourth stop rods 1102 are arranged in a sliding manner between the four similar seventh stop rods 1102. Movable block 1104, the fourth movable block 1104 cooperates with the movable rod 1100, and four eighth sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com