Immersing tool for solar welding strips

A solar ribbon and tooling technology, applied in auxiliary devices, manufacturing tools, welding equipment, etc., can solve the problems of ribbon bending and softening, and achieve the effect of preventing bending and ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

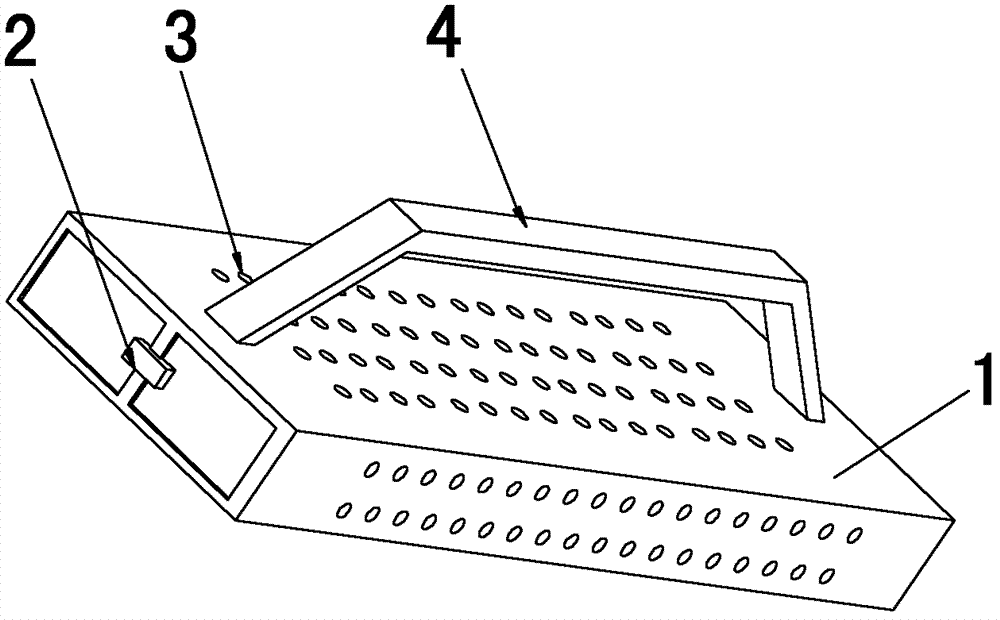

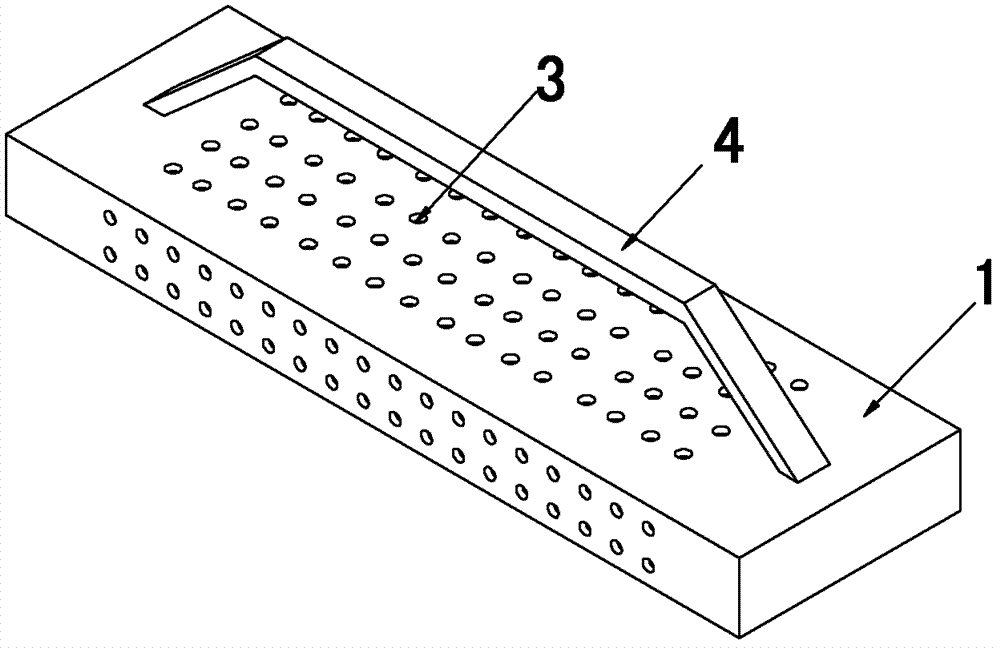

[0010] see figure 1 , figure 2 , the solar welding ribbon soaking tool of the present invention includes a box body 1 for placing the welding ribbon, one end surface of the box body is provided with a closeable opening 2, and the upper, lower and two sides of the box body are provided with multiple A leak hole 3. A handle 4 is connected to the top of the box body. The length of the cavity inside the box matches the length of the welding strip to be soaked. The specific size of the tooling can be made according to different lengths of welding strips.

[0011] When soaking the welding ribbon, first open the opening, put all the welding ribbon into the tooling and lay it flat, and close the opening. Submerge the entire tooling in the flux solution, and grab the handle and shake it left and right in the flux to fully soak the solder strip. After soaking for a certain period of time according to the requirements of the process time, take the tooling out of the flux solution a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com