Wire feeding mechanism of welding machine

A wire feeding mechanism and welding machine technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve problems such as welding wire blocking, poor welding, enterprise loss, etc., to reduce tin explosion and prevent leakage The effect of welding, precision wire feeding or wire withdrawal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

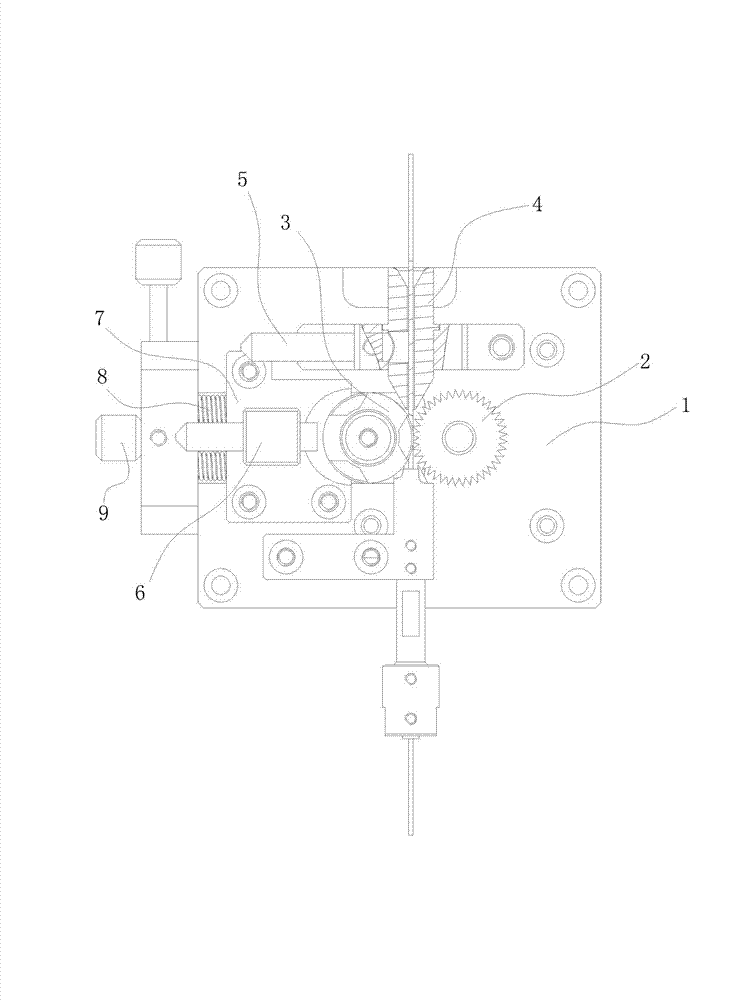

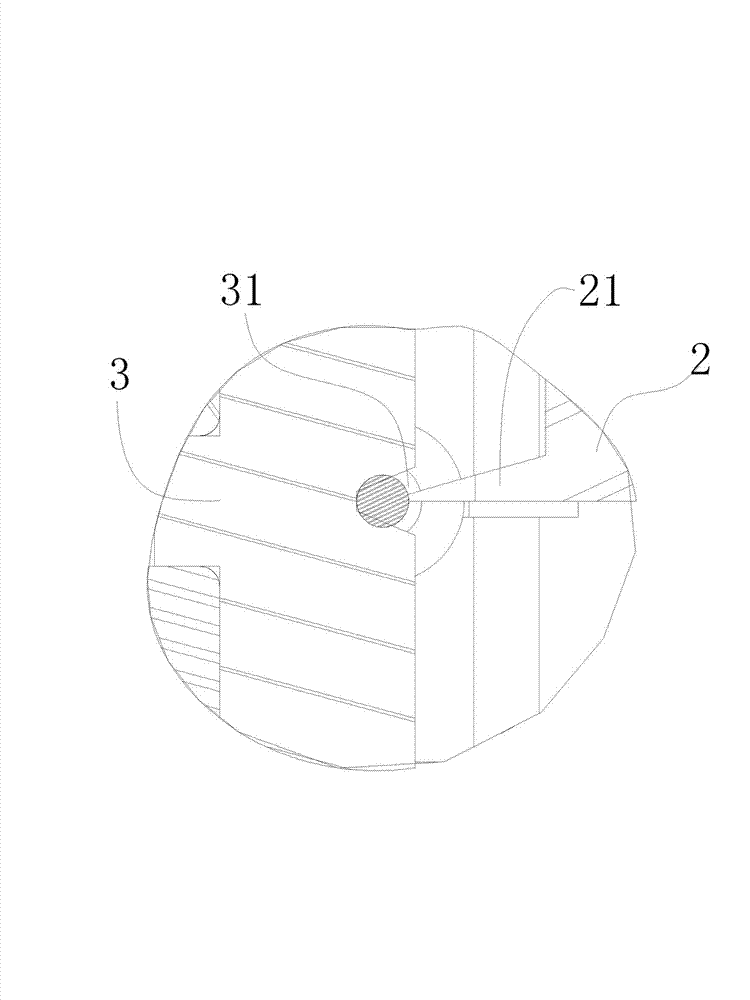

[0014] Example: see figure 1 and figure 2 , a wire feeding mechanism of a welding machine in the present invention, which includes a machine base 1, which also includes a wire feeding gear 2, a wire jam induction wheel 3, a welding wire guide block 4, a first sensor 5 and a second sensor 6. The wire jam induction wheel 3 is rotatably set on a slide plate 7, and the slide plate 7 is set on the machine base 1 so as to slide left and right, and the left end and several ends of the slide plate 7 are fixed on the machine base 1 The pressure spring 8 at the left end is connected, and the wire feeding gear 2 and the wire jamming induction wheel 3 are arranged on the base 1 in a level manner, and there is a gap between the wire feeding gear 2 and the wire jamming induction wheel 3 for the welding wire to pass through. gap, the welding wire guide block 4 is arranged directly above the gap, the first sensor 5 is arranged on the base 1 and is facing the welding wire guide block 4, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com