Belt type automatic-cleaning coal feeder

A technology for automatic cleaning and coal loading, applied in cleaning devices, conveyors, conveyor objects, etc., can solve problems such as operator's health injury, belt conveyor inoperable, increase labor production costs, etc., to prevent casualties, Simple structure and the effect of reducing labor cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

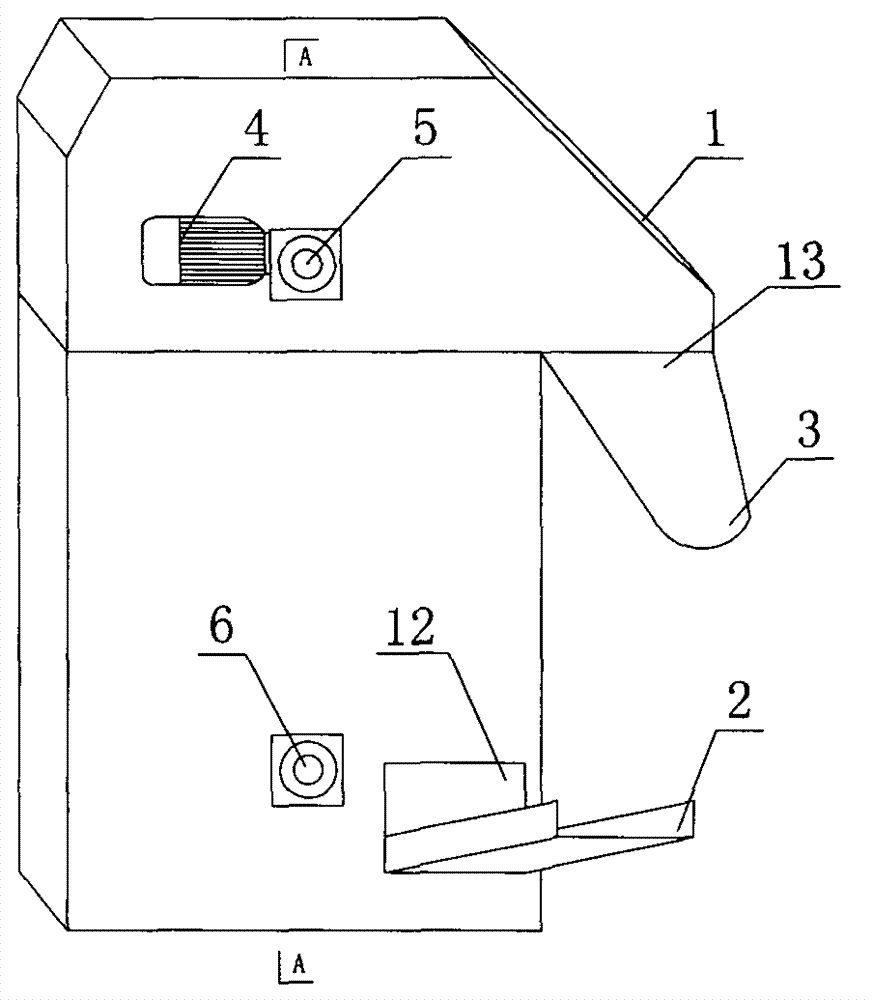

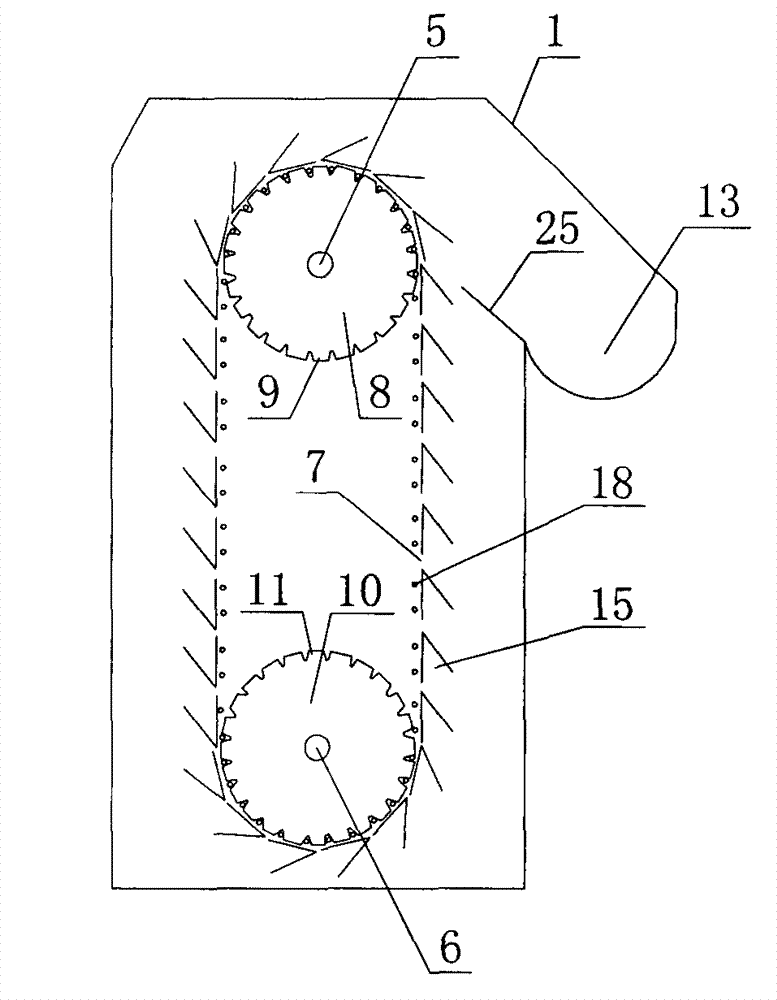

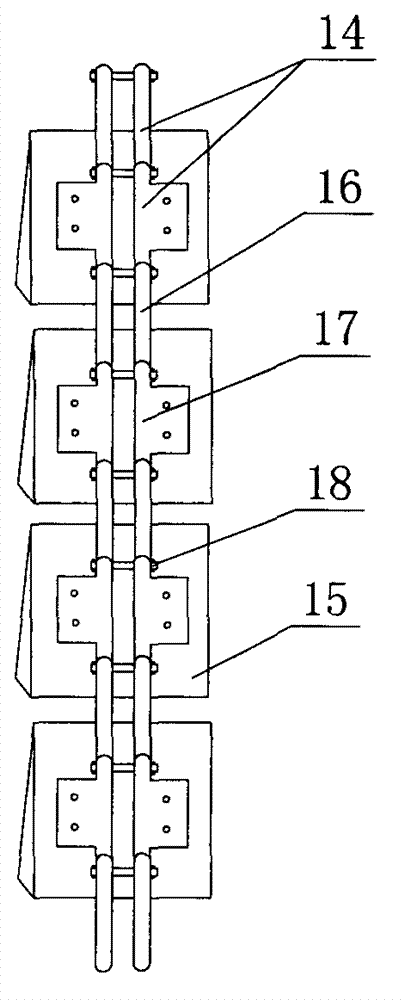

[0015] Such as figure 1 , figure 2 As shown, the belt automatic cleaning coal loader of the present embodiment is provided with a body 1, a hopper 2, a hopper 3, a motor 4, a driving wheel 5, a driven wheel 6 and a loading and unloading conveying device 7. The two ends of the driving wheel 5 are fixedly connected on both sides of the upper part of the body 1 through two bearings respectively, the outer end of the driving wheel 5 protruding from the body 1 is engaged with the motor 4, and the driving wheel 5 is fixedly provided with a driving wheel chainring 8, the driving wheel The driving wheel teeth 9 are equidistantly arranged around the toothed disc 8 . The two ends of the driven wheel 6 are fixedly connected on both sides of the bottom of the body 1 by two bearings respectively, and the driven wheel 6 is fixedly provided with a driven wheel toothed disc 10 which is equal in shape and size to the driving wheel 5, and the periphery of the driven wheel toothed disc 10 is e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com