Thulium-holmium co-doped zirconia upconversion phosphor and preparation method thereof

A technology of co-doping and phosphor powder, applied in the field of phosphor powder

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

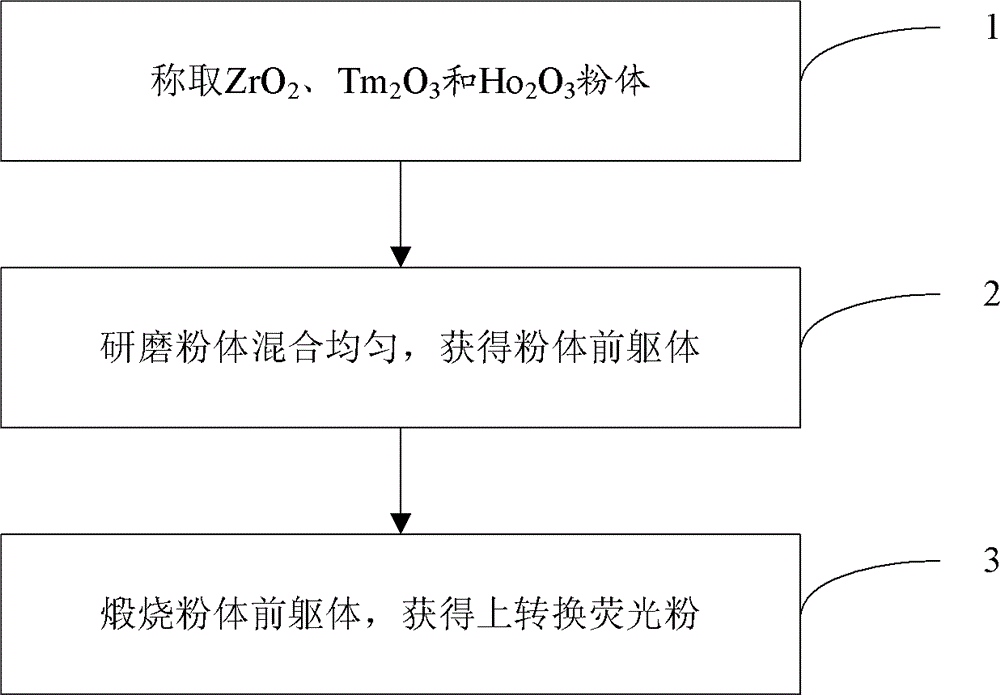

[0016] The preparation method of the above-mentioned thulium-holmium co-doped zirconia up-conversion phosphor, such as figure 1 As shown, its preparation process steps are as follows:

[0017] Step S1, weighing ZrO with a mass ratio of 1.04 to 1.2: 0.2 to 1.17: 0.17 to 1.7 2 、Tm 2 o 3 and Ho 2 o 3 Powder;

[0018] Step S2, grinding and mixing the powder in step S1 for 20 to 60 minutes (preferably 40 minutes), to obtain a uniformly mixed powder precursor;

[0019] Step S3, putting the powder precursor in step S2 into a calcination device (such as a muffle furnace), calcination treatment at 800-1300°C (preferably 1150°C) for 0.5-5h (preferably 3h), and then cooling to room temperature , the general chemical formula is Zr 1-y-x o 2 :xTm 3+ ,yHo 3+ The thulium-holmium co-doped zirconia up-conversion phosphor; wherein, Zr 1-y-x o 2 is the matrix, Tm and Ho are doping elements, the value range of x is 0.01-0.06, and the value range of y is 0.01-0.1.

[0020] In the ab...

Embodiment 1

[0024] 1. Weigh 1.11g of ZrO powder 2 , Tm of 0.78g 2 o 3 and 1.02g of Ho 2 o 3 ;

[0025] 2. Grind and mix the powder in step 1 in a corundum mortar for 40 minutes to make it evenly mixed to obtain the powder precursor;

[0026] 3. Put the corundum mortar containing the powder precursor in step 2 into a muffle furnace, and burn it at 1150°C for 3 hours; then cool it to room temperature and take it out to obtain Zr 0.9 o 2 :0.04Tm 3+ , 0.06Ho 3+ Thulium-holmium co-doped zirconia up-conversion phosphor.

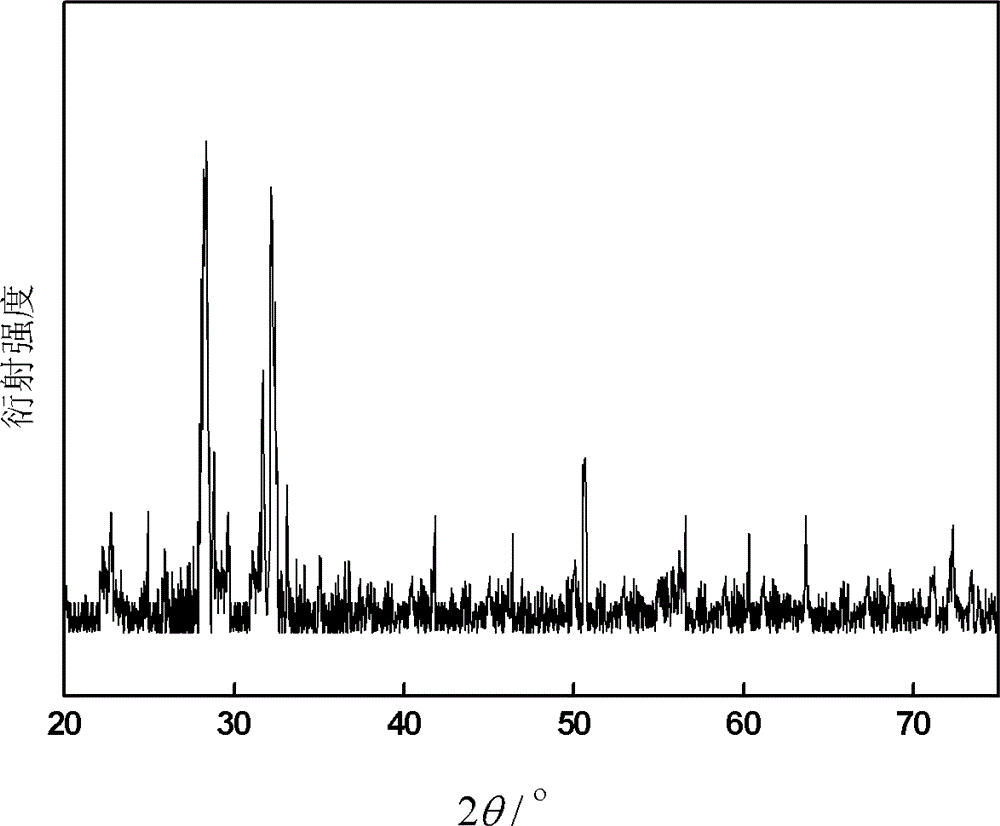

[0027] figure 2 It is the YRD figure of the thulium-holmium co-doped zirconia up-conversion phosphor powder obtained in Example 1; figure 2 It can be seen that compared with the standard PDF card, the diffraction peaks show the crystal orientation of monoclinic zirconia and tetragonal zirconia. There were no impurity peaks and no peaks of rare earth ions; indicating that the ions were doped into the crystal lattice of zirconia.

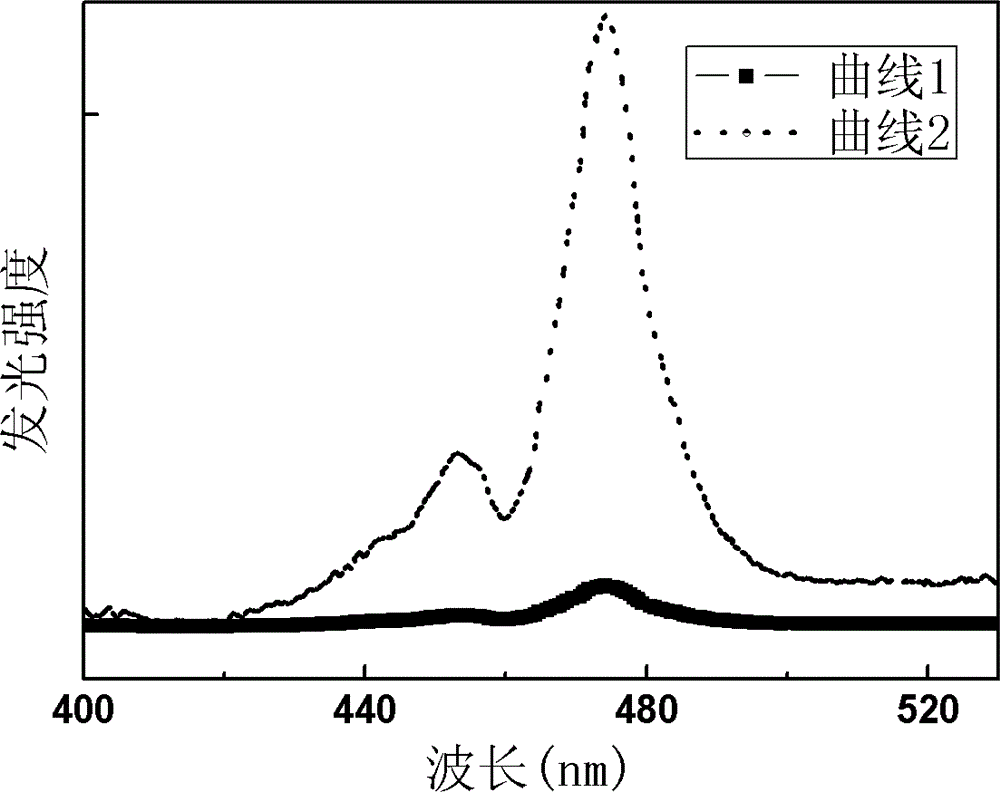

[0028] image 3 Be that embodime...

Embodiment 2

[0030] 1. Weigh 1.2g of ZrO powder 2 , Tm of 0.2g 2 o 3 and 0.17g of Ho 2 o 3 ;

[0031] 2. Grind and mix the powder in step 1 in a corundum mortar for 20 minutes to make it evenly mixed to obtain the powder precursor;

[0032] 3. Put the corundum mortar containing the powder precursor in step 2 into a muffle furnace, and burn it at 800°C for 0.5h; then cool it to room temperature and take it out to obtain Zr 0.98 o 2 :0.01Tm 3+ , 0.01Ho 3+ Thulium-holmium co-doped zirconia up-conversion phosphor.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com