Electronic jacquard needle selection solenoid valve

A technology of solenoid valves and flower pillows, which is applied in jacquard machines, textiles, textiles, and papermaking, etc., can solve the problems of heavy coil frame weight, deformation, and increased coil frame weight, and achieve reliable and accurate operation, reduce use costs, and be replaceable strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

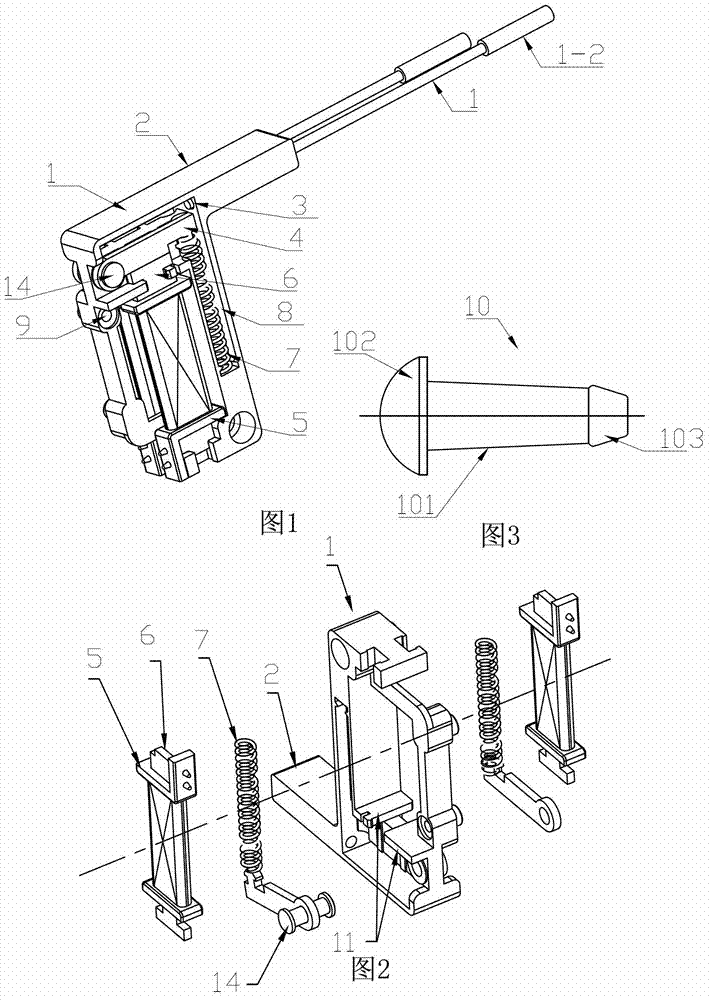

[0023] Example 1: Electronic flower pillow needle selection solenoid valve, such as figure 1 , figure 2 As shown, it includes a valve seat 1 with an installation chamber for the actuator, an actuator assembly installed in the installation chamber, a guide column 2 arranged at one end of the valve seat 1 and extending outward, passing through the guide column 2 and on the valve There is a push pin channel of the push pin hole 3 at the corresponding position of the seat 1 , and the actuator assembly cooperates with the push pin hole 3 to realize the opening or closing of the push pin hole 3 .

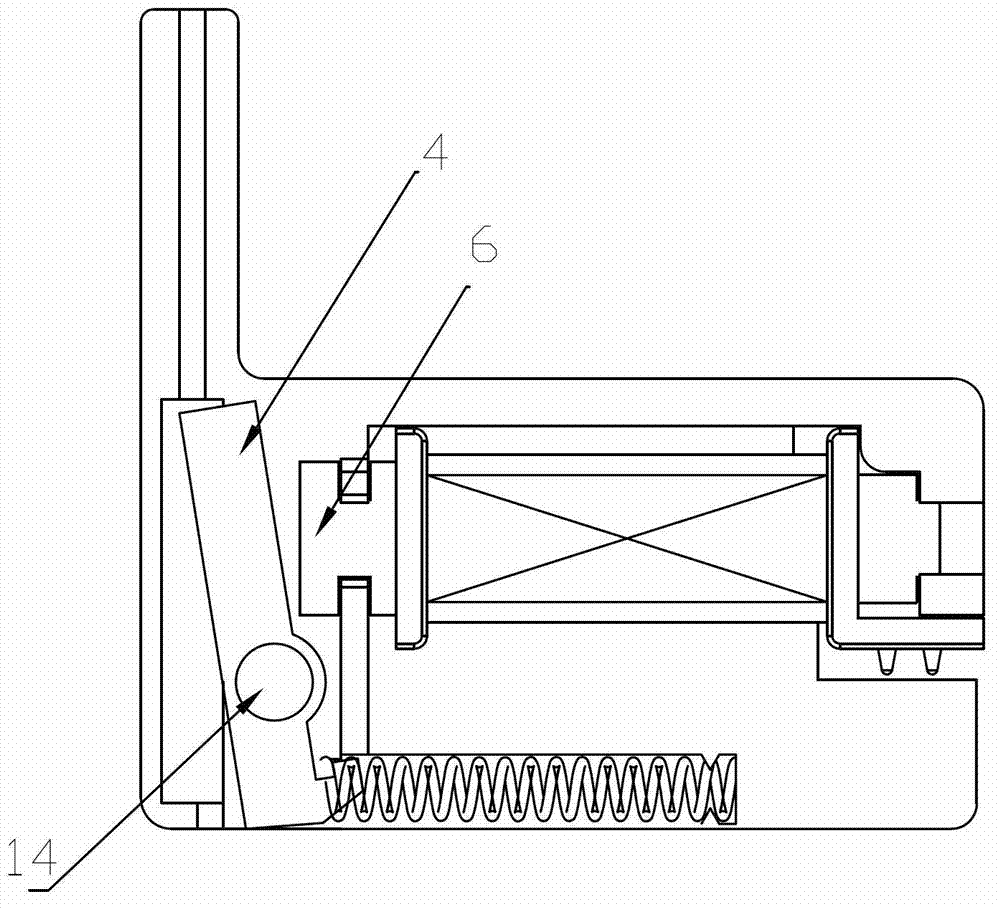

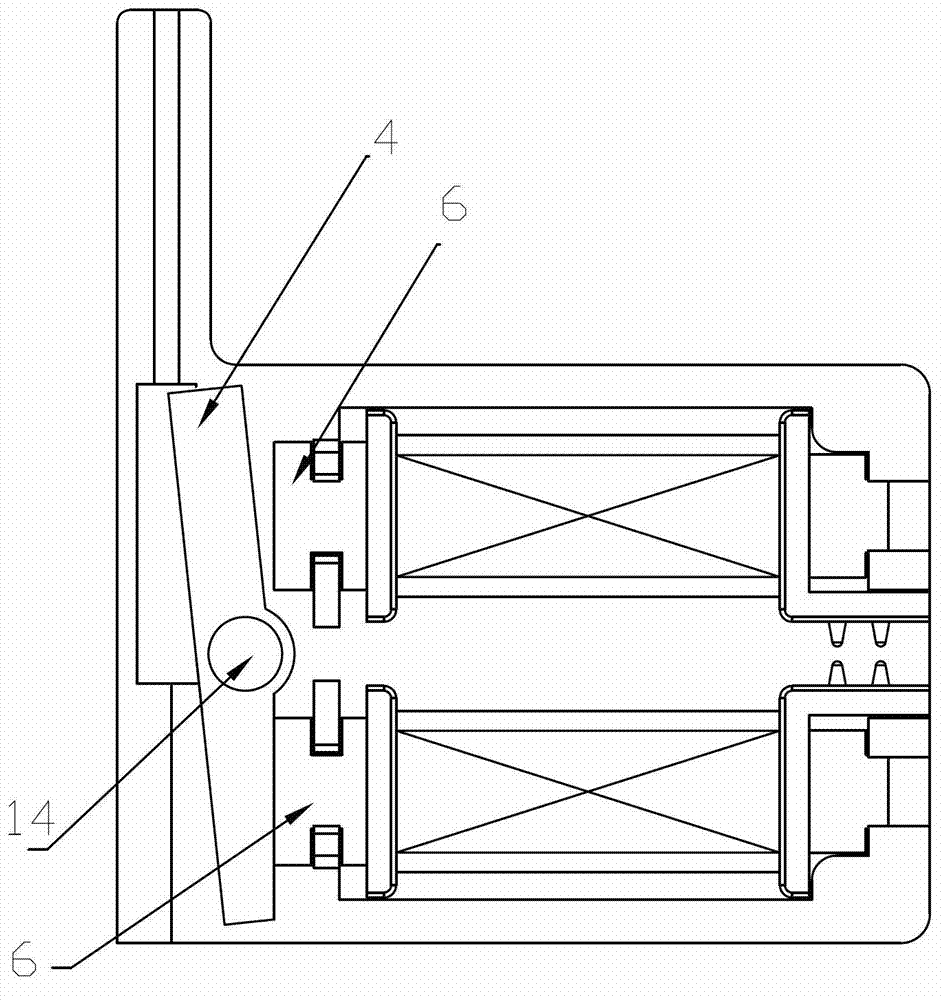

[0024] Specifically, the executive assembly includes a swing arm 4 that is pivotally connected to the valve seat 1 through a pivot 14 and whose working end corresponds to the push pin hole 3, and a power assembly that drives the swing arm 4 to open and close the push pin hole 3. The power assembly includes at least The electromagnet and push-pull parts, the electromagnet includes a c...

Embodiment 2

[0034] Example 2: Electronic flower pillow needle selection solenoid valve, the other end of the swing arm 4 away from the working end is the pivot end, the push-pull member is another electromagnet, the working ends of the two iron cores 6 are respectively connected with the middle part of the swing arm 4 and the swing arm 4 working end fit. When working, only one electromagnet is energized. The rest of the structure is the same as that of Embodiment 1. Those skilled in the art can realize the technical solution through the above description. In order to save space, the schematic diagram of the structure is omitted.

Embodiment 3

[0035] Example 3: Electronic flower pillow needle selector solenoid valve, such as Figure 4 As shown, the middle part of the swing arm 4 is a pivot part, the push-pull member is a spring 7, and the spring 7 and the electromagnet are respectively arranged on both sides of the pivot part. The rest of the structure is the same as that of Embodiment 1. Those skilled in the art can realize the technical solution through the above description. In order to save space, the schematic diagram of the structure is omitted.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com